Blog

- Home

- Blog

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

In the intricate world of plumbing and HVAC systems, the T valve emerges as a crucial component that facilitates efficient water flow and temperature regulation. Defined by its unique three-way design, the T valve plays a pivotal role in directing fluid movement within complex piping networks. According to industry reports, the global plumbing market is projected to grow significantly, with a compound annual growth rate (CAGR) of around 6% over the next several years, highlighting the increasing importance of reliable components like T valves. Furthermore, the HVAC industry is expected to reach a market size of $280 billion by 2023, with T valves being integral in achieving energy-efficient systems. Understanding the functionalities, types, and applications of T valves is essential for professionals aiming to optimize performance and ensure longevity in plumbing and HVAC installations.

In the intricate world of plumbing and HVAC systems, the T valve emerges as a crucial component that facilitates efficient water flow and temperature regulation. Defined by its unique three-way design, the T valve plays a pivotal role in directing fluid movement within complex piping networks. According to industry reports, the global plumbing market is projected to grow significantly, with a compound annual growth rate (CAGR) of around 6% over the next several years, highlighting the increasing importance of reliable components like T valves. Furthermore, the HVAC industry is expected to reach a market size of $280 billion by 2023, with T valves being integral in achieving energy-efficient systems. Understanding the functionalities, types, and applications of T valves is essential for professionals aiming to optimize performance and ensure longevity in plumbing and HVAC installations.

What Are T Valves and Their Function in Plumbing and HVAC?

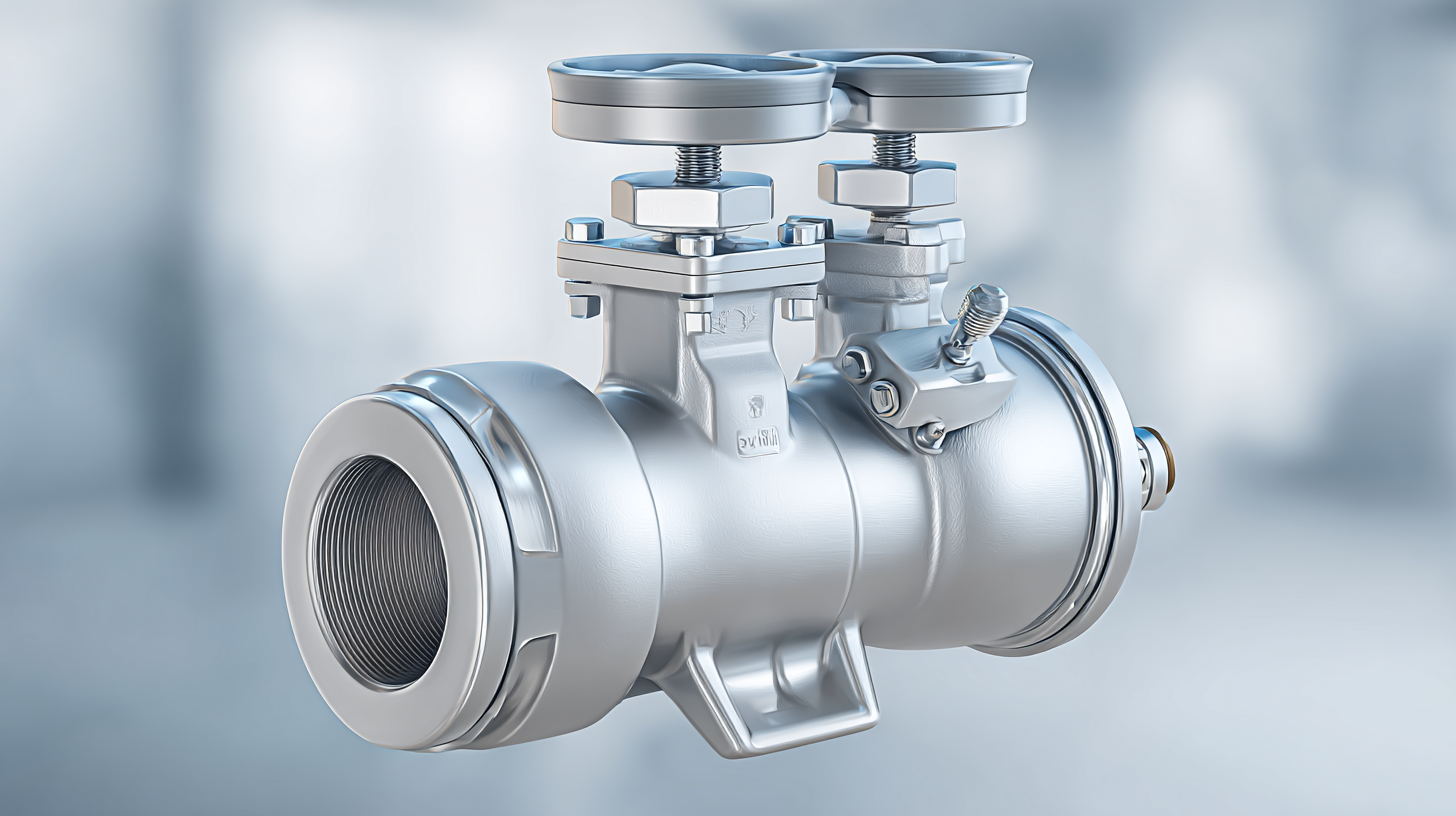

T valves are crucial components in plumbing and HVAC systems, serving as directional control devices that manage the flow of fluids. They are designed to either direct or split the flow into multiple pathways, which is essential for regulating the temperature and pressure in heating and cooling systems. According to industry reports, proper maintenance and monitoring of these valves can significantly impact the efficiency and longevity of HVAC systems, preventing costly repairs and ensuring optimal performance.

With the rising costs of home repairs, understanding common plumbing sounds can help homeowners identify issues early. Experts warn that sounds like groaning, gurgling, or water hammer could indicate serious problems, such as main pipe blockages. Matthew Ferris emphasizes the importance of having a reputable plumber on hand to avoid emergencies that may arise from neglected plumbing systems. Data suggests that over 2.5 million homeowners experience water leaks annually, underscoring the value of regular plumbing maintenance, including checking and servicing essential components like T valves. By addressing these elements proactively, homeowners can enhance their home’s reliability and reduce the likelihood of expensive repairs.

Types of T Valves: A Comprehensive Overview of Styles and Designs

T valves are essential components in plumbing and HVAC systems, facilitating the efficient control of fluid flow. They come in various styles and designs, each tailored for specific applications. One of the most common types is the standard T valve, which allows flow from one inlet to two outlets or vice versa. This design is particularly useful in irrigation systems or heating applications, where redistributing fluid is necessary.

Another notable style is the multi-port T valve, which provides additional versatility. These valves can manage multiple paths for fluid to travel, making them suitable for complex HVAC systems where different zones require distinct temperature settings. Additionally, there are specialized T valves, such as ball valves and gate valves, designed for specific purposes. Ball valves provide quick shut-off capabilities, while gate valves are ideal for applications where minimal pressure drop is critical. Understanding these various designs is fundamental for selecting the right T valve for your system's needs and ensuring optimal performance.

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

| Type of T Valve | Material | Application | Pressure Rating |

|---|---|---|---|

| Plastic T Valve | PVC | Water supply | 150 PSI |

| Brass T Valve | Brass | Heating systems | 400 PSI |

| Stainless Steel T Valve | Stainless Steel | Chemical transfer | 300 PSI |

| Cast Iron T Valve | Cast Iron | Sewage systems | 250 PSI |

| Aluminum T Valve | Aluminum | Air conditioning | 200 PSI |

The Importance of T Valves in Fluid Control and System Regulation

T valves play a crucial role in fluid control and system regulation within plumbing and HVAC systems. These valves, often used to divert or mix fluids, contribute significantly to efficiency and performance in various applications. According to a report by the American Society of Plumbing Engineers (ASPE), well-designed T valves can improve system efficiency by up to 15%, highlighting their importance in both residential and commercial plumbing systems.

In HVAC applications, T valves are essential for maintaining desired temperature and pressure levels. A study conducted by the International Institute of Refrigeration reveals that improper valve selection and placement can lead to energy losses of nearly 20%. By ensuring correct installation and operation of T valves, HVAC systems can achieve a more balanced thermal environment and reduce energy consumption, effectively supporting sustainability goals. With the ongoing push for energy efficiency in modern infrastructure, understanding and utilizing T valves is more important than ever for optimizing system performance.

Applications of T Valves in Residential and Commercial Systems

T valves play a crucial role in both residential and commercial plumbing and HVAC systems, serving as essential components that facilitate the flow and direction of fluids. In residential systems, T valves are commonly used to control the water supply to various fixtures, such as sinks, showers, and appliances. These valves can efficiently split the flow from a single pipe into two separate lines, allowing for improved water distribution throughout the home. Homeowners benefit greatly from the reliability of T valves, as they help maintain consistent pressure and reduce the risk of clogs in the plumbing system.

In commercial applications, the use of T valves extends beyond basic water distribution. They are vital in HVAC systems, where they help regulate heating and cooling by directing the flow of air or refrigerant. In larger buildings, T valves enable the efficient management of temperature control across multiple zones, ensuring comfort for occupants. Their robust design and versatility make them suitable for a variety of settings, from office complexes to industrial facilities. As such, understanding the applications of T valves is essential for anyone involved in plumbing or HVAC maintenance, highlighting their importance in promoting system efficiency and reliability.

Maintenance Tips for Ensuring Optimal Performance of T Valves

Maintaining T valves is crucial for ensuring the efficient operation of plumbing and HVAC systems. According to the American Society of Plumbing Engineers, a well-maintained valve can enhance system performance by 15-20%. Regular inspections are key; professionals recommend checking for leaks, corrosion, and wear at least twice a year. Identifying minor issues early can prevent costly repairs and system failures down the line.

In addition to routine inspections, proper lubrication of T valves can significantly improve their lifespan and functionality. The National Institute of Standards and Technology has noted that inadequately lubricated valves can lead to a 30% increase in operating torque, causing strain on the entire system. Furthermore, cleaning the valve seats from debris build-up ensures a tight seal, minimizing the risk of flow restrictions that can reduce system efficiency. Implementing these maintenance practices can help achieve optimal performance and reliability in your plumbing and HVAC applications.

(780) 669-9420

(780) 669-9420