Blog

- Home

- Blog

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

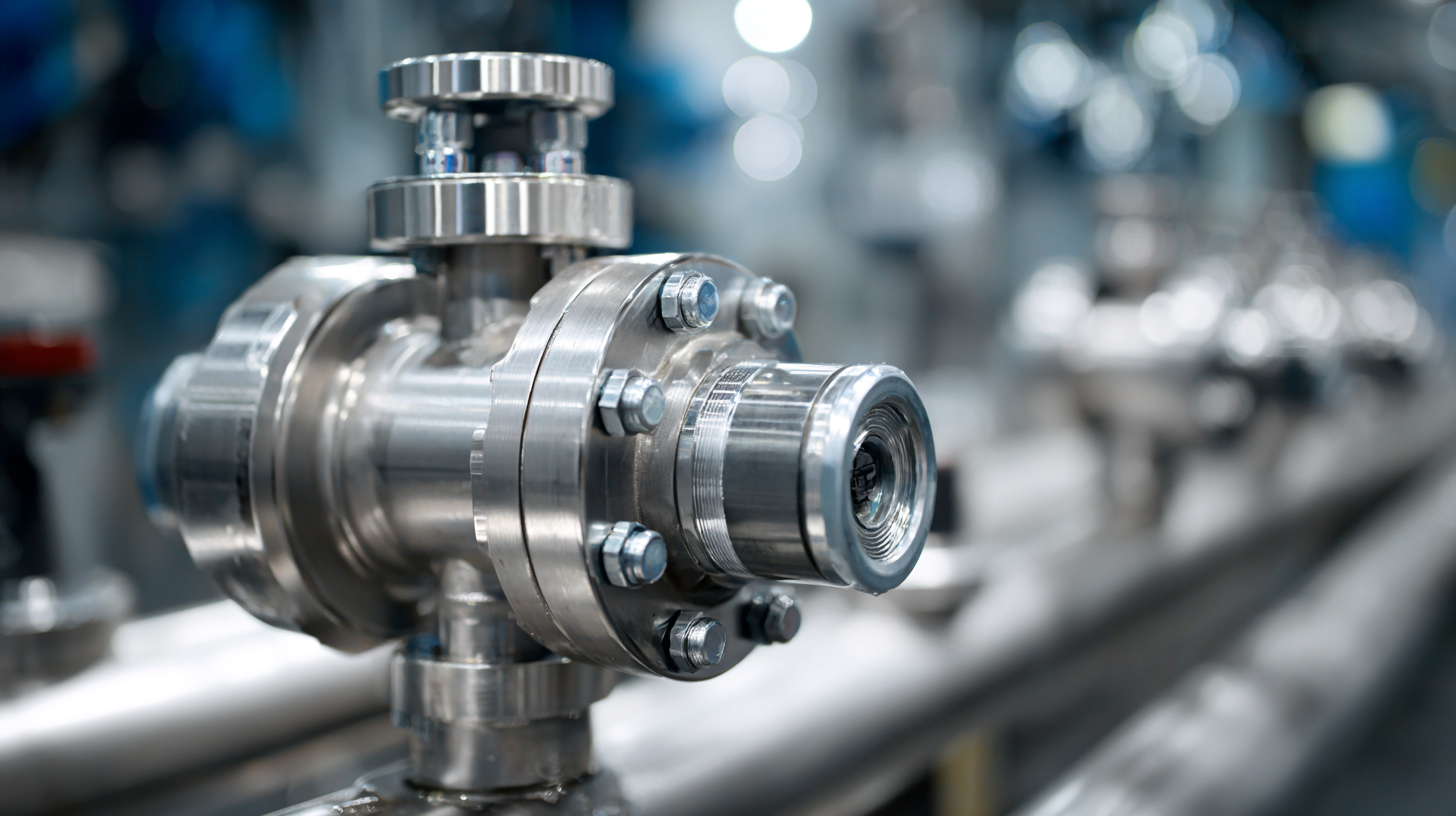

In the realm of modern engineering, fluid control stands as a cornerstone of efficiency and precision, and at the heart of this process lies the single valve system. Understanding how to effectively implement and utilize single valve technology is crucial for engineers aiming to optimize fluid dynamics in various applications. These systems, characterized by their simplicity and reliability, allow for seamless control of fluid flow, reducing the complexity typically associated with multi-valve arrangements. This article explores the fundamental principles behind single valve systems, offering insights into their design, operational efficiency, and integration into contemporary engineering projects. By mastering the mechanics and advantages of single valve solutions, engineers can enhance system performance, minimize potential failures, and contribute to more sustainable practices in fluid management.

Benefits of Implementing Single Valve Systems in Fluid Dynamics

The implementation of single valve systems in fluid dynamics has become a game-changer for modern engineering, providing numerous benefits that enhance efficiency and performance. According to a report by the Fluid Control Institute, adopting single valve systems can reduce energy consumption by as much as 30% compared to traditional multi-valve arrangements. This reduction is primarily due to the streamlined design, which minimizes pressure loss and optimizes flow rates, resulting in lower operational costs for businesses.

Furthermore, single valve systems contribute significantly to simpler maintenance processes. A study published in the Journal of Fluid Engineering highlights that systems with single valves require 50% less maintenance time, which translates into operational uptime and productivity increases. This simplification not only decreases labor costs but also mitigates the risks associated with complex valve configurations that are often prone to faults due to multiple moving parts. As industries increasingly shift towards more sustainable practices, the ability to harness the advantages of single valve systems will be pivotal in driving innovation and efficiency in fluid control applications.

Key Principles of Fluid Control in Engineering Applications

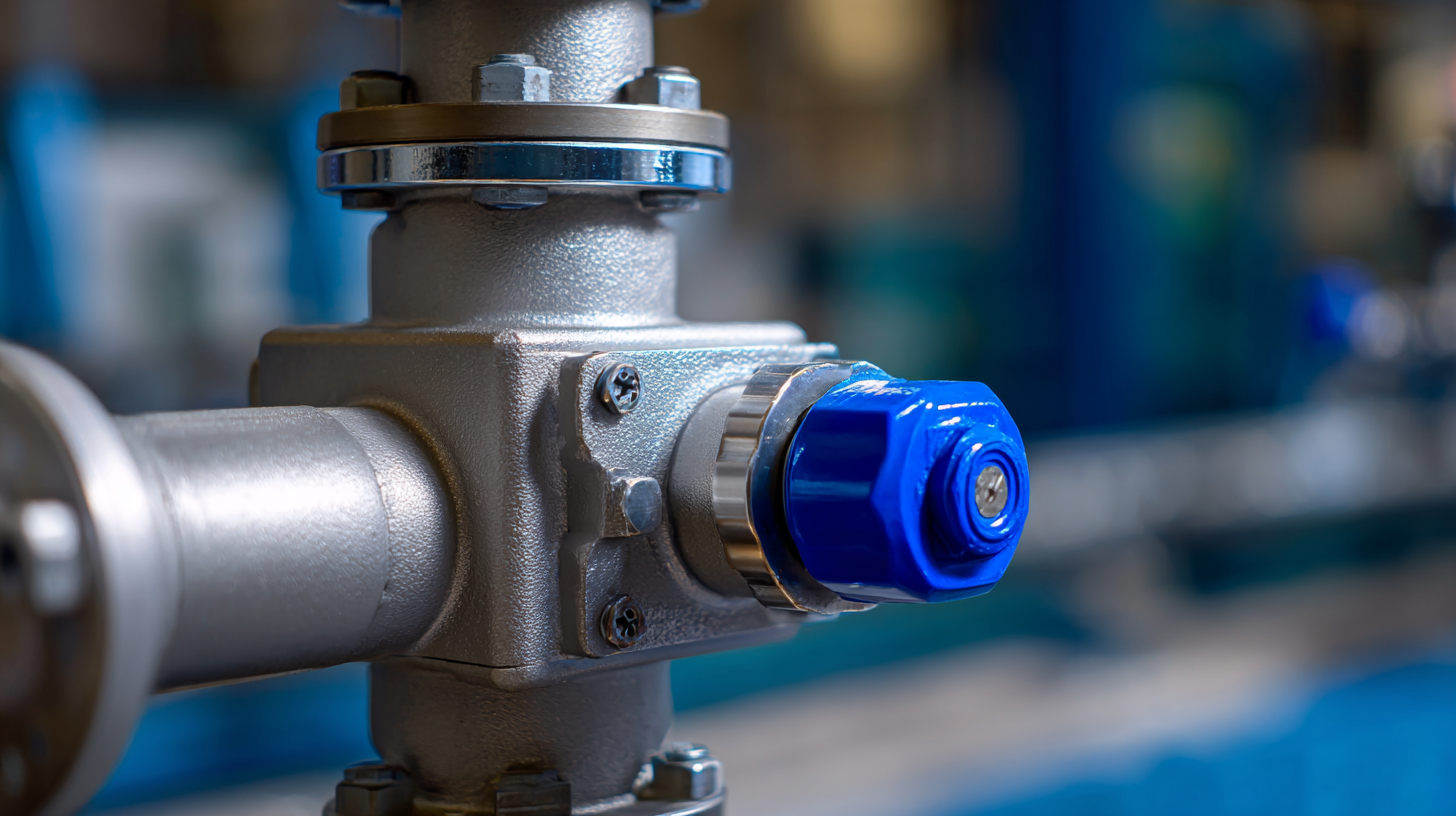

In modern engineering, fluid control is pivotal in ensuring the efficiency and reliability of various applications. Single valve systems are designed to simplify the management of fluid flow, enabling precise control over pressure and volume. By using a single valve, engineers can minimize the complexity of the system, reducing potential points of failure and improving maintenance efficiency. This streamlined approach enhances the overall performance and safety of fluid systems across numerous industries, from manufacturing to chemical processing.

Tip: Always consider the material compatibility of the valve with the fluids being handled. Using the right materials will prevent corrosion or degradation, ensuring longevity and reliability in your fluid control systems.

The key principles of fluid control involve understanding the dynamics of flow, pressure regulation, and the importance of response time. Engineers must focus on how these elements interact within a system, ensuring that the design can accommodate fluctuations while maintaining optimal performance. Moreover, the integration of smart technologies, such as sensors and automated control systems, plays a crucial role in modern fluid control strategies.

Tip: Regularly test and calibrate your fluid control systems to ensure they are functioning as intended. This proactive approach helps in identifying potential issues before they escalate, maintaining operational efficiency.

Common Challenges in Single Valve Systems and Their Solutions

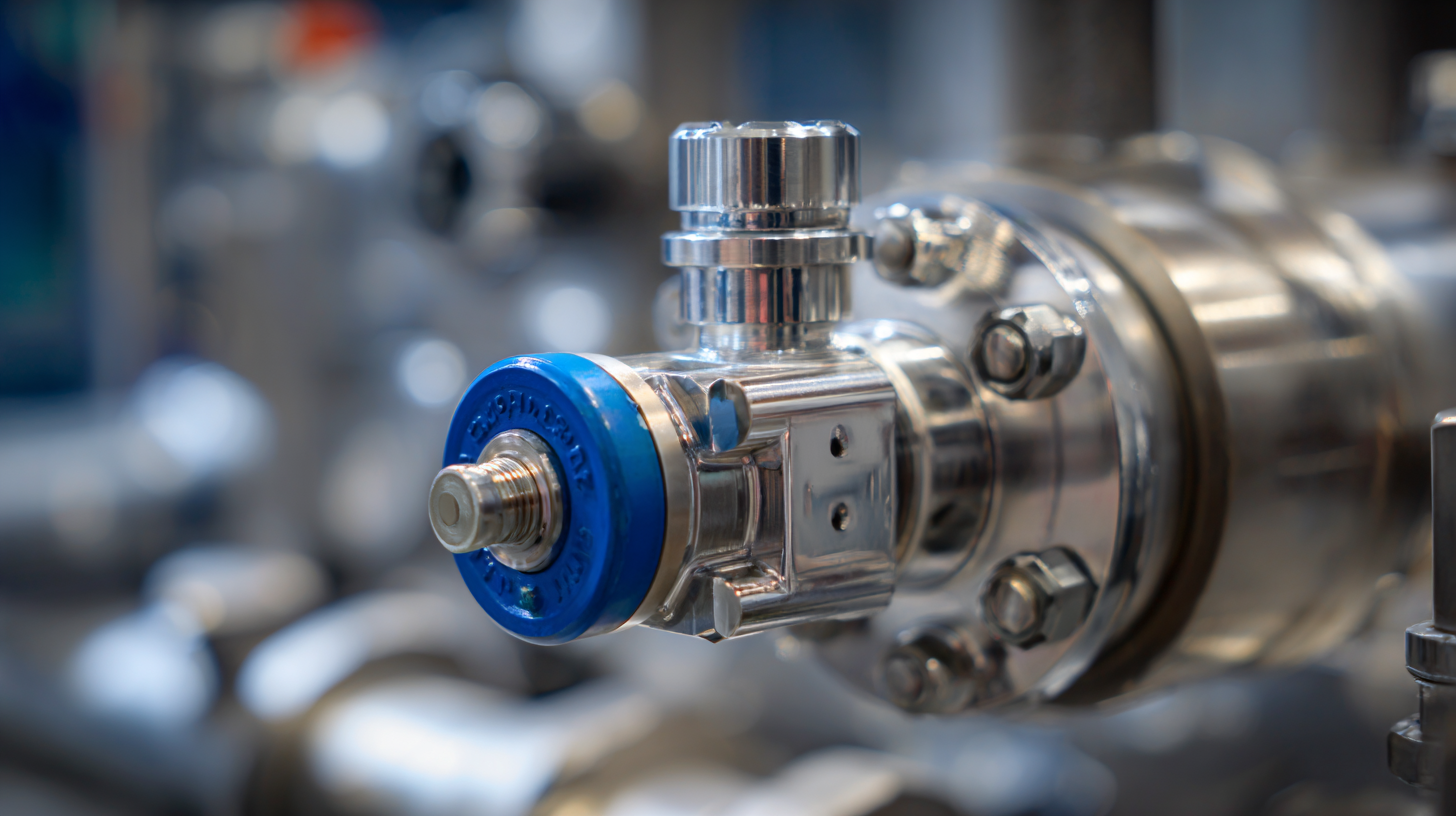

Single valve systems play a crucial role in efficient fluid control within various engineering applications.

However, common challenges often arise, particularly concerning the reliability and performance of these systems. For instance, malfunctioning components such as valves can lead to significant operational disruptions.

A recent report highlighted that leaky valves in light rail cars caused reduced service reliability, underscoring the importance of regular maintenance and immediate troubleshooting. By addressing these issues, engineers can mitigate potential failures and enhance overall system efficiency.

Moreover, advancements in technology are paving the way for innovative solutions to these common challenges. The introduction of new optimized valves in industries such as water treatment demonstrates a proactive approach to improving system performance.

These advancements not only enhance fluid control but also reduce repair costs associated with typical faults, such as unreasonable parameter settings in control systems of turbo-generators.

By systematically diagnosing and addressing these common failures, engineers can significantly improve the functionality and lifespan of single valve systems, adhering to best practices for fluid management in modern engineering.

Innovative Techniques for Optimizing Valve Performance

Single valve systems play a crucial role in fluid control across various engineering applications. Innovations in valve technology have made it possible to optimize performance, ensuring that systems operate at maximum efficiency. By incorporating advanced materials and designs, engineers can enhance the responsiveness and reliability of valves, leading to better fluid management in processes ranging from water treatment to chemical production.

Tips: To enhance valve performance, consider regular maintenance checks to identify wear and tear. Additionally, optimizing the valve sizing and selection based on the specifics of the fluid being managed can greatly increase efficiency. Using smart sensors can also facilitate real-time monitoring, helping to preempt issues before they escalate.

The implementation of innovative techniques, such as computational fluid dynamics (CFD) modeling, allows engineers to simulate and analyze flow behavior through single valve systems. This not only assists in identifying potential areas for improvement but also aids in the development of solutions that can minimize energy consumption. Adaptation of such technologies ensures that modern engineering can meet the evolving demands of fluid control with precision and sustainability.

Tips: Always assess the mounting location of valves to ensure that they are free from vibration or stress, which can lead to premature failure. Mobile monitoring systems can also track performance data and maintenance needs, ensuring optimal operation over time.

Case Studies: Success Stories of Single Valve Applications

In modern engineering, single valve systems have revolutionized the approach to fluid control, offering efficiency and reliability in various applications. One notable success story can be found in the oil and gas industry. A major offshore drilling operation utilized a single valve system to regulate the flow of drilling mud, significantly reducing the risk of spills and enhancing worker safety. The implementation of this technology not only streamlined operations but also improved the precision of fluid management, leading to a more sustainable approach to resource extraction.

In modern engineering, single valve systems have revolutionized the approach to fluid control, offering efficiency and reliability in various applications. One notable success story can be found in the oil and gas industry. A major offshore drilling operation utilized a single valve system to regulate the flow of drilling mud, significantly reducing the risk of spills and enhancing worker safety. The implementation of this technology not only streamlined operations but also improved the precision of fluid management, leading to a more sustainable approach to resource extraction.

Another compelling case study is in the food and beverage industry, where a leading manufacturer adopted a single valve system for pasteurization processes. This system allowed for precise temperature control and consistent flow rates, ensuring product quality while minimizing waste. As a result, the company saw a marked increase in production efficiency and a decrease in energy consumption, demonstrating how single valve systems can contribute to both cost savings and improved environmental impact. These examples highlight the versatility and effectiveness of single valve applications across diverse engineering fields.

(780) 669-9420

(780) 669-9420