Blog

- Home

- Blog

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

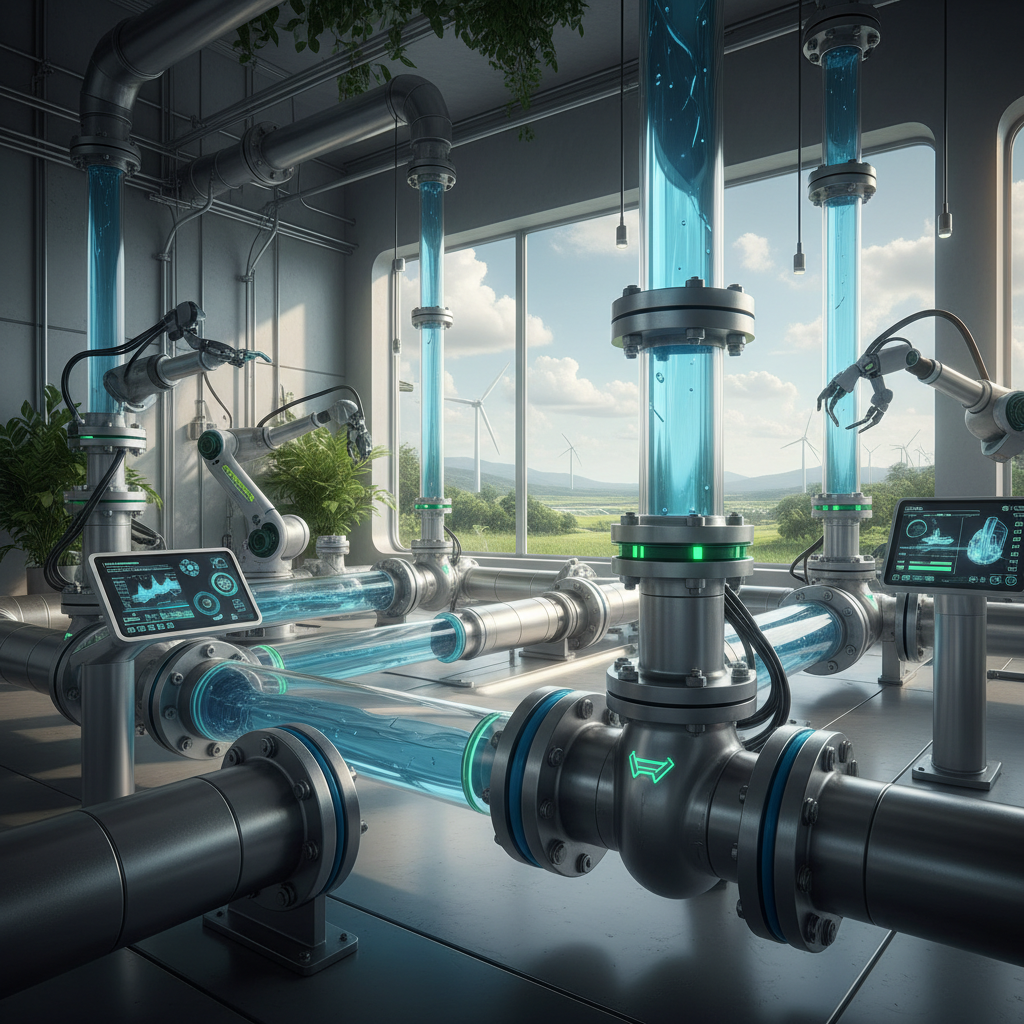

In the landscape of fluid management, the role of valve control has become increasingly pivotal. As industries strive for efficiency, sustainability, and reliability, the advancements in valve control technologies are revolutionizing how fluids are managed across various applications. This article delves into the top ten innovations set to shape the future of valve control by the year 2025, highlighting how these breakthroughs can optimize processes, reduce waste, and enhance energy efficiency.

From smart sensors that provide real-time data to automated systems capable of adaptive control, the innovations discussed here are designed to address the growing demands for precision and dependability in fluid management. Each innovation not only represents a leap forward in technology but also underscores the importance of integrating advanced solutions into existing infrastructure. By exploring these transformative trends, we aim to equip professionals with the knowledge to harness the power of modern valve control systems and drive significant improvements in their operations.

2025: Advanced Smart Valve Technologies Driving Efficiency in Fluid Management

The landscape of fluid management is undergoing a transformative shift in 2025, largely driven by advanced smart valve technologies. These innovations promise not just enhanced efficiency but also a more responsive approach to fluid control within various industrial applications. Smart valves equipped with IoT capabilities allow for real-time monitoring and adjustments, optimizing flow rates and reducing energy consumption. By integrating sensors and data analytics, these systems can detect anomalies and perform predictive maintenance, significantly minimizing downtime and operational costs.

Moreover, the implementation of artificial intelligence in valve control systems is paving the way for adaptive management of fluid systems. AI algorithms can analyze vast amounts of operational data to optimize valve performance dynamically, ensuring that resources are allocated effectively. This level of intelligence not only boosts efficiency but also enhances safety measures within complex fluid management networks. As industries increasingly prioritize sustainability and cost-effectiveness, smart valve technologies stand at the forefront of this evolution, transforming the way fluids are managed, monitored, and controlled.

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

| Innovation | Description | Efficiency Improvement (%) | Key Benefits |

|---|---|---|---|

| Smart IoT Valves | Valves integrated with IoT for data collection and remote monitoring. | 30 | Real-time data analytics, predictive maintenance |

| Electro-Pneumatic Actuators | Combining electrical and pneumatic control for enhanced precision. | 25 | High precision, reduced energy consumption |

| Self-Diagnosing Valves | Valves that can monitor their own health and performance. | 20 | Improved reliability, reduced downtime |

| Wireless Control Systems | Allowing valve controls without the need for extensive wiring. | 28 | Flexible installation, reduced installation costs |

| Automated Flow Control | Systems that automatically adjust flow based on demand. | 35 | Optimized resource use, enhanced process control |

| Adaptive Control Algorithms | Learning algorithms that optimize valve response to conditions. | 22 | Improved efficiency, reduced losses |

| Compact Valve Designs | Space-saving designs that maintain performance. | 15 | Integration flexibility, space efficiency |

| Cloud-Connected Systems | Cloud-based management systems for global monitoring. | 27 | Centralized control, enhanced decision-making |

| Biomimetic Valves | Valves inspired by biological systems for better fluid dynamics. | 30 | Enhanced flow characteristics, reduced turbulence |

AI-Powered Predictive Maintenance Solutions Enhancing Valve Lifespan and Reliability

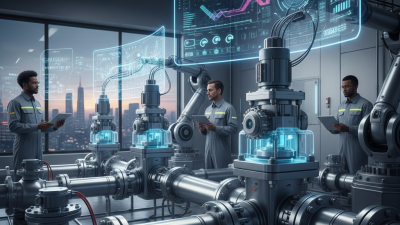

The advent of AI-powered predictive maintenance solutions is revolutionizing valve control systems, particularly in fluid management applications. These technologies leverage large datasets and advanced analytics to forecast potential failures before they occur, thus significantly extending the lifespan of valves. By continuously monitoring the operational parameters of the valves, AI systems can identify patterns that precede mechanical failure, allowing for timely interventions. As a result, organizations are shifting from reactive maintenance strategies to proactive approaches, reducing downtime and maintenance costs in the process.

Furthermore, these AI-driven solutions not only enhance reliability but also optimize overall system performance. With real-time diagnostics, operators can make informed decisions regarding valve operations, ensuring that fluid management remains efficient. This synergy between AI technology and valve control signifies a crucial step towards smarter industrial processes, where automation and data analytics coalesce to create more resilient and efficient fluid management systems. As industries adopt these innovations, we can expect a marked improvement in energy savings, production reliability, and environmental sustainability.

Integration of IoT for Real-Time Monitoring in Valve Control Systems

The integration of Internet of Things (IoT) technology in valve control systems marks a significant shift toward more efficient fluid management.

Real-time monitoring capabilities allow operators to gain instantaneous insights into valve performance and fluid dynamics, offering unprecedented opportunities for optimization. According to a 2023 report by MarketsandMarkets, the global IoT in the industrial sector is projected to grow from $20 billion in 2022 to over $50 billion by 2025, reflecting the rising demand for smart solutions in fluid control.

Real-time monitoring capabilities allow operators to gain instantaneous insights into valve performance and fluid dynamics, offering unprecedented opportunities for optimization. According to a 2023 report by MarketsandMarkets, the global IoT in the industrial sector is projected to grow from $20 billion in 2022 to over $50 billion by 2025, reflecting the rising demand for smart solutions in fluid control.

Real-time data collection and analytics capabilities provided by IoT systems enable predictive maintenance, reducing downtime and enhancing operational efficiency. A study conducted by McKinsey indicates that predictive maintenance can decrease maintenance costs by up to 25% and improve equipment lifespan by 30%. By integrating sensors and smart actuators into valve systems, operators can remotely monitor parameters such as pressure, temperature, and flow rates, allowing for immediate corrective actions and further enhancing process reliability. As the industry progresses toward automation, the role of IoT in valve control will become crucial for achieving tight fluid management and operational excellence.

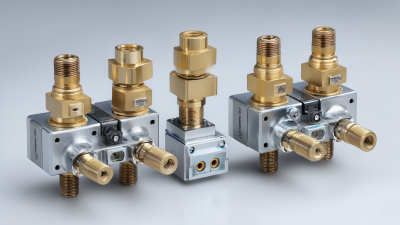

Impact of 3D Printing on Custom Valve Design for Increasing Efficiency

The integration of 3D printing technology into the design and manufacturing of valves is revolutionizing efficient fluid management. By enabling the production of customized valve designs, 3D printing addresses specific operational challenges, such as turbulence and pressure loss, which have traditionally impacted flow dynamics within gate valves. Recent studies highlight the importance of understanding these flow dynamics to optimize valve performance, emphasizing that tailored solutions can significantly enhance functionality and efficiency.

Furthermore, companies are leveraging 3D printing to create bespoke hydraulic valves that not only meet but exceed industry standards. This approach allows for rapid prototyping and production, leading to quicker deployment of critical parts across the globe. The customization capabilities afforded by 3D printing result in valves that are optimized for specific conditions, as demonstrated by successful implementations in various industrial settings, including power plants. This trend indicates a shift toward more adaptive manufacturing processes that prioritize efficiency and effectiveness in fluid management systems.

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

Sustainable Valve Solutions: Reducing Environmental Footprint in Fluid Management Systems

In today's rapidly evolving technological landscape, sustainable valve solutions are emerging as key players in minimizing the environmental impact of fluid management systems. With industries increasingly prioritizing eco-friendly practices, innovative valve designs are being developed to conserve resources, reduce waste, and minimize energy consumption. These advancements not only lead to enhanced operational efficiency but also support compliance with stringent environmental regulations.

One notable innovation is the integration of smart sensors and automated controls in valve systems, allowing for real-time monitoring and precise adjustments. This technology ensures optimal fluid flow while minimizing leaks and emissions, thus contributing to a greener operational footprint. Furthermore, the use of biodegradable materials and energy-efficient components in valve manufacturing exemplifies the commitment to sustainability, empowering companies to adopt fluid management systems that align with their environmental goals.

As the demand for sustainable solutions grows, the focus on reducing the environmental footprint in fluid management will continue to drive innovations in valve control technology. By embracing these sustainable practices, industries not only enhance their competitiveness but also play a crucial role in protecting our planet for future generations.

Related Posts

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

-

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Why Forged Steel Valves Are Essential for Industrial Applications

(780) 669-9420

(780) 669-9420