Blog

- Home

- Blog

Top Gate Valve Types Explained for Your Industrial Needs?

In the industrial sector, **gate valves** play a critical role in flow control. According to a recent report by the Research Institute of Valve Technology, the global gate valve market is projected to grow by 4% annually. This growth reflects the increasing demand for reliable flow management in various applications. Industry expert Dr. Emily Hartman emphasizes this, stating, "Gate valves are fundamental in ensuring safety and efficiency in industrial processes."

Despite their importance, many industries overlook the nuances of gate valve types. Each type serves specific operational needs, and understanding these differences is essential. For instance, rising temperatures and pressures can affect valve performance. A misapplication can lead to inefficiencies or even failures, highlighting the need for proper selection.

Moreover, the maintenance of gate valves is often underestimated. Regular inspections can prevent unexpected downtimes. However, some operators may ignore these best practices, which can lead to serious operational hitches. A deeper exploration of gate valve types and their applications is not just informative; it is crucial for sustaining industrial efficiency.

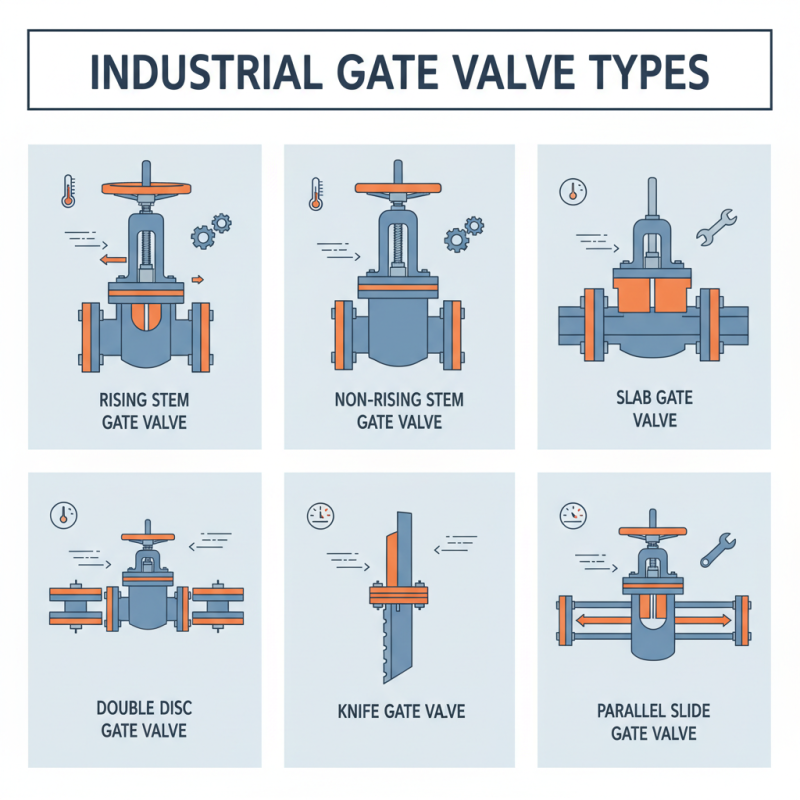

Types of Gate Valves Commonly Used in Industrial Applications

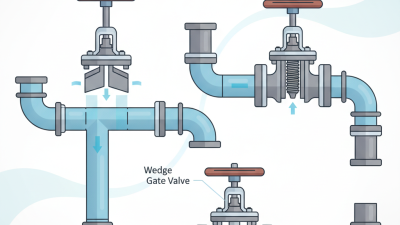

Gate valves are crucial in many industrial applications. They control fluid flow with precision and reliability. Two common types include wedge gate valves and parallel gate valves. Each has unique benefits and limitations.

Wedge gate valves are often used in high-pressure systems. They can handle large volumes of fluid. Industry data suggests that these valves account for nearly 70% of gate valve usage in oil and gas sectors. However, they can be slow to open and close, which might lead to operational delays.

Parallel gate valves excel in applications requiring quick responses. They have a straightforward design that minimizes flow obstruction. Yet, they may not seal as tightly as wedge types. According to a recent report, more than 50% of water treatment facilities prefer parallel gate valves for their efficiency. Choosing the right valve type can be challenging. Each application presents specific requirements, and what works for one may not suit another. It’s essential to evaluate the operational context.

Top Gate Valve Types Used in Industrial Applications

This chart illustrates the relative usage frequency of various gate valve types in industrial applications, highlighting the Wedge Gate Valve as the most commonly used type, followed by Parallel and Slab Gate Valves.

Characteristics of Wedge Gate Valves and Their Uses

Wedge gate valves are popular in industrial applications. Their design features two wedge-shaped pieces. This shape allows for a tight seal when closed. They are widely used in piping systems. The main advantage is their ability to handle high pressure.

Wedge gate valves work well with liquids and gases. They can also handle slurries effectively. The construction is durable. However, they may require manual operation. This can sometimes be inconvenient in automated systems. Regular maintenance is essential to prevent leaks.

Tips:

Always check the sealing surfaces for wear. This ensures the valve operates smoothly. Additionally, consider the flow direction. Installing valves the wrong way can lead to malfunctions. Make sure to use the right size. A poorly sized valve can impact system performance.

Benefits of Parallel Gate Valves in Pipeline Systems

Parallel gate valves are essential in pipeline systems. They offer several advantages, especially in high-flow applications. These valves can maintain consistent flow rates, reducing turbulence. Their design allows for a full-open position which promotes efficient fluid transport.

One key benefit is their ability to handle large volumes of fluid. With less restriction, parallel gate valves reduce energy costs. They tend to have longer lifespans due to their robust construction. However, regular maintenance is crucial to ensure optimal performance. Neglecting routine checks can lead to unexpected failures.

Another aspect to consider is their installation. While parallel gate valves are versatile, they require precise alignment. Misalignment during installation can cause operational issues. Maintenance can be tricky in tight spaces. This may challenge technicians trying to access the valve for repairs. Understanding both the benefits and limitations can lead to better decisions in industrial applications.

Comparing Rising Stem and Non-Rising Stem Gate Valves

Gate valves play a crucial role in industrial applications. They come in various designs, including rising stem and non-rising stem types. Understanding these two can enhance your industrial system's efficiency.

Rising stem gate valves provide visual confirmation of the valve's position. When you turn the handwheel, the stem rises with the disc. This type is beneficial when you need to monitor operations visually. However, they require more vertical space. If your setup has limited room, consider this limitation carefully.

On the other hand, non-rising stem gate valves save space. The stem remains in place while the disc moves up and down. They are ideal for confined areas. Yet, without a visual indicator, knowing the valve's status can be tricky. This could lead to inconvenient situations during maintenance or unexpected shutdowns.

Tips: Always assess your space before choosing a gate valve type. If visibility is essential, opt for rising stem types. Ensure proper training for staff on valve operation and maintenance. A well-informed team can avert operational hiccups.

Factors to Consider When Selecting a Gate Valve for Industrial Needs

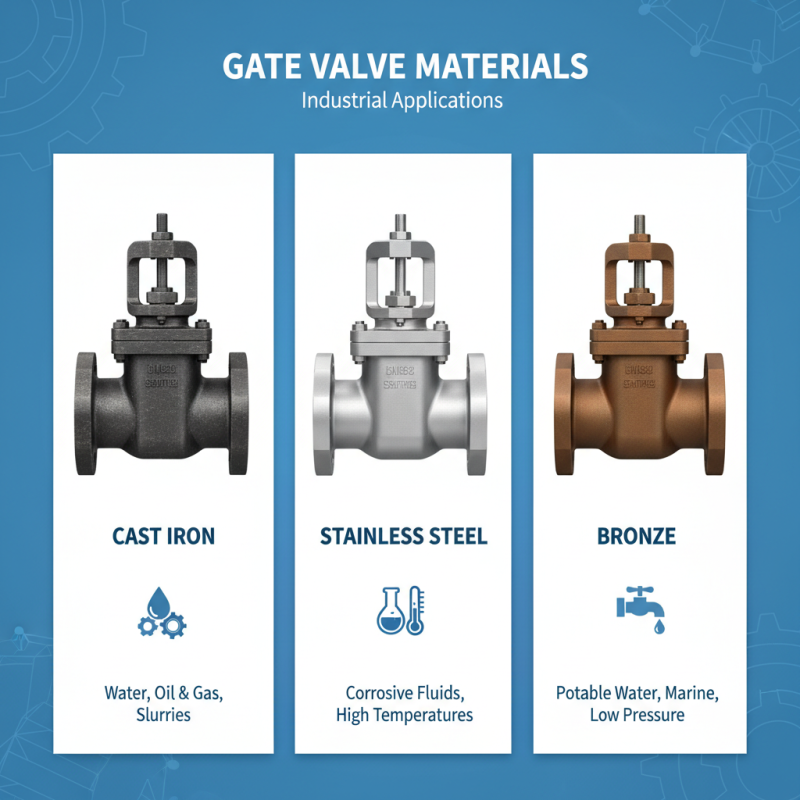

When selecting a gate valve for industrial applications, several factors come into play. The first is the valve size. Correct sizing ensures optimal flow rates and prevents leaks. A valve that’s too large may not seal properly, while one too small can cause pressure loss. Material choice also matters. Choosing the right material helps resist corrosion and wear. Common materials include cast iron, stainless steel, and bronze. Each serves a different purpose based on the fluid type.

Another important consideration is the operating pressure. Valves need to handle the specific pressure of the system. Overlooking this can lead to failures or safety hazards. Pay attention to the temperature range as well. High temperatures may require special materials or designs. Lastly, installation type affects valve selection. Some valves are better for horizontal while others suit vertical installations. Reflecting on these factors can prevent costly mistakes. Each decision layer impacts overall performance.

Related Posts

-

2026 Top Gate Valve Types for Your Industrial Applications?

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose DHV Gate Valve for Your Industrial Applications

(780) 669-9420

(780) 669-9420