Blog

- Home

- Blog

Top 10 Engineered Solutions Transforming Modern Industries?

In today’s rapidly evolving world, engineered solutions play a pivotal role in transforming industries. Experts like Dr. Emily Chen, a leading innovator in industrial engineering, emphasize, “Engineered solutions are reshaping how we approach challenges in every sector.” This statement highlights the profound impact of tailored technologies in contemporary practices.

Industries across the globe are experiencing a significant shift. From advanced manufacturing to sustainable energy, engineered solutions are essential. They introduce efficiency and optimize performance. However, the journey is not always smooth. Integration challenges and resistance to change can impede progress.

As we explore the top ten engineered solutions, it’s crucial to recognize their potential and limitations. Each solution brings unique benefits, but they also demand adaptability and careful consideration. Balancing innovation with practicality can be daunting. Moving forward, reflection on past implementations will guide future advancements in engineered solutions.

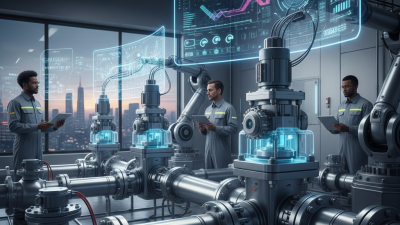

The Role of Artificial Intelligence in Smart Manufacturing Solutions

In the realm of smart manufacturing, artificial intelligence plays a crucial role. According to a report by McKinsey, AI could contribute up to $3.7 trillion in value annually in the manufacturing sector. This is a significant shift in how industries operate. Companies are leveraging AI to streamline production processes and enhance efficiency.

AI technologies enable predictive maintenance. They analyze machinery data to predict failures before they occur. This reduces downtime and lowers maintenance costs. A specific study found that companies using AI for predictive maintenance could decrease their maintenance costs by 10-30%. Yet, full implementation remains a challenge. Many manufacturers are still hesitant to adopt these advanced tools.

Furthermore, AI-driven automation can optimize supply chains. Intelligent algorithms manage inventories and logistics. They respond to market changes in real time. While this offers immense potential, discrepancies still exist. Some industries lag in digital maturity, struggling with integration. Genuine transformation requires a cultural shift within organizations, not just technological upgrades. Embracing such changes is pivotal for achieving long-term success in modern manufacturing.

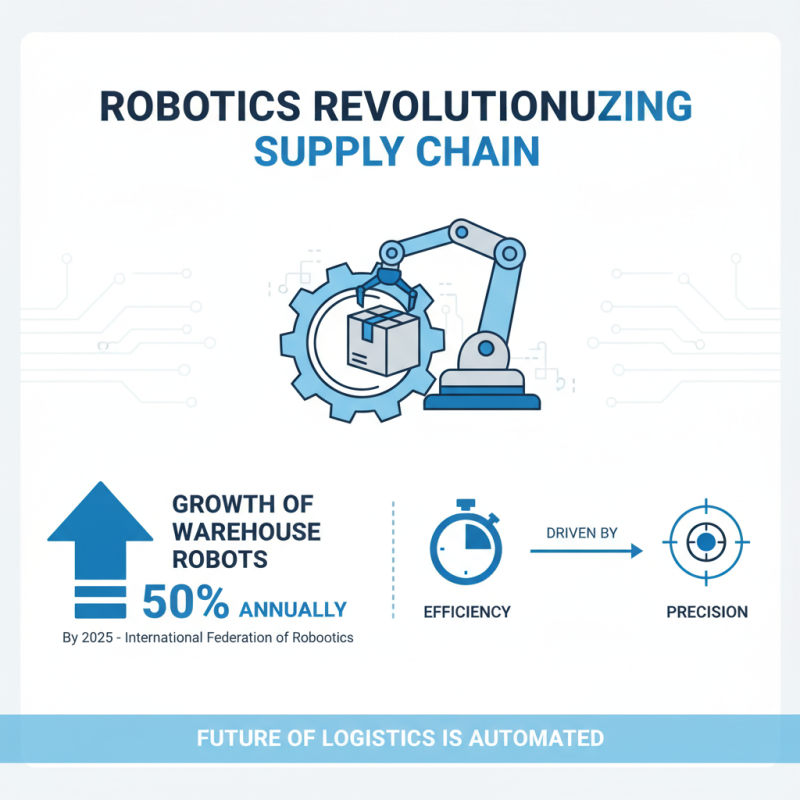

Advancements in Robotics Revolutionizing Supply Chain Management

The supply chain management landscape is undergoing a dramatic transformation due to advancements in robotics. A report by the International Federation of Robotics indicated that by 2025, the growth of warehouse robots could reach 50% annually. This shift is primarily driven by the need for efficiency and precision in logistics.

Robots are no longer mere assembly line workers. They now sort, store, and retrieve goods in massive warehouses. These machines enhance productivity by operating 24/7. However, reliance on automation invites scrutiny. Human jobs are at risk, and the quality of control may diminish without adequate oversight. Some reports suggest that up to 20 million jobs could be lost in the next decade if companies do not plan for reskilling.

Data from McKinsey reveals that robotic solutions reduce supply chain costs by up to 30%. Yet, integrating robotics is not seamless. Many companies face challenges in retraining their workforce to coexist with robotic systems. Balancing technology with human insight remains a delicate task. Companies must consider this as they push forward. The benefits are evident, but the potential downsides warrant cautious implementation. How will the future workforce adapt to these rapid changes? Only time will tell.

The Impact of IoT-Driven Solutions on Industrial Efficiency Metrics

The rise of IoT-driven solutions is significantly impacting industrial efficiency metrics. Smart sensors and connected devices gather real-time data. This enables industries to monitor processes closely. For instance, manufacturers can track machine performance continuously. They identify potential failures before they happen. This proactive approach reduces unexpected downtimes.

However, reliance on technology comes with challenges. Not all IoT solutions are intuitive. Some require extensive training for staff. This can lead to confusion and errors if not managed properly. Additionally, not every company is ready to embrace these changes. Resistance to new technology can stifle innovation.

**Tip:** Start with small IoT pilots in your operations. Assess what works before scaling up.

Another critical factor is data security. With more connected devices, vulnerabilities increase. Companies must prioritize securing their networks. Neglecting this aspect can lead to significant breaches, disrupting operations.

**Tip:** Regularly update software and conduct security audits. Ensure your team is trained on cybersecurity protocols.

Monitoring efficiency metrics with IoT is powerful. However, a careful, strategic approach is essential. Balancing technology with human expertise will yield the best outcomes.

Top 10 Engineered Solutions Transforming Modern Industries

| Solution | Industry | Efficiency Improvement (%) | Implementation Cost (USD) | Return on Investment (ROI) |

|---|---|---|---|---|

| Predictive Maintenance | Manufacturing | 20% | $50,000 | 150% |

| Asset Tracking | Logistics | 25% | $30,000 | 200% |

| Robotic Process Automation | Finance | 30% | $100,000 | 250% |

| Smart Energy Management | Utilities | 15% | $80,000 | 180% |

| Supply Chain Management | Retail | 22% | $40,000 | 190% |

| Smart Manufacturing | Manufacturing | 28% | $200,000 | 300% |

| Real-time Analytics | Healthcare | 18% | $75,000 | 170% |

| Telematics Solutions | Transport | 24% | $70,000 | 210% |

| Quality Control Automation | Pharmaceuticals | 26% | $120,000 | 220% |

| Digital Twin Technologies | Construction | 30% | $90,000 | 260% |

Sustainable Engineering Practices in Renewable Energy Industries

Sustainable engineering plays a crucial role in transforming the renewable energy sector.

Advanced solutions are being developed to harness natural resources.

Solar panels, wind turbines,

and bioenergy systems are common examples. Each technology comes with its own challenges.

For instance, solar energy relies heavily on weather conditions. This can limit its efficiency.

Wind energy presents its own complexities as well. The placement of turbines is vital for optimum energy capture.

However, wildlife protection needs to be considered. There are often trade-offs between energy output and environmental impacts.

Engineers must constantly innovate to address these concerns. New materials and designs are emerging, but issues remain.

Sustainable practices are not without their flaws.

Recycling efforts for old systems are often inadequate.

Additionally, the production process of renewable technologies can be resource-intensive.

Engineers face the dilemma of balancing production needs with sustainability goals.

Continuous reflection and improvement are essential to achieve true sustainability in the energy sector.

Big Data Analytics Transforming Predictive Maintenance Strategies

Predictive maintenance is evolving, driven by big data analytics. Industries are now able to anticipate equipment failures before they occur. Analyzing vast amounts of data from machinery, companies can identify patterns that suggest when maintenance is necessary. This proactive approach reduces downtime significantly. Yet, implementing these strategies is not without challenges.

Data quality remains a critical issue. Many organizations struggle with inconsistent or incomplete data. Without accurate information, predictions can be misleading. As a result, businesses must invest in data cleansing processes. Ensuring the integrity of data can enhance reliability in predictions.

Moreover, there is a need for skilled personnel who can interpret data effectively. The gap between technology and human capability can hinder progress. Organizations understand the value of predictive maintenance, but they must refine their strategies. Continuous learning and adaptation are crucial in this fast-paced landscape. Only then can companies truly harness the power of big data in their maintenance approaches.

Top 10 Engineered Solutions Transforming Modern Industries

This bar chart illustrates the impact of big data analytics on predictive maintenance strategies across different sectors. The data reflects the percentage improvement in maintenance efficiency due to the adoption of advanced analytics.

Related Posts

-

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

-

10 Best Gate Valves You Need to Know About

-

Top Gate Valve Types Explained for Your Industrial Needs?

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

How to Fix a Working Valve Issues Troubleshooting Guide

-

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

(780) 669-9420

(780) 669-9420