Blog

- Home

- Blog

Tips for Maintaining Your Working Valve Effectively?

Maintaining a working valve is crucial for optimal performance in various industries. According to a report by the American Society of Mechanical Engineers, over 60% of valve failures are due to inadequate maintenance. This highlights the importance of regular inspections and timely repairs. A well-maintained working valve not only enhances efficiency but also extends equipment life.

Ignoring regular maintenance can lead to costly downtime. In some sectors, valve malfunctions can result in production losses exceeding $100,000 per day. Such figures emphasize the need for proactive measures. Simple tasks like lubrication and leak checks can make a significant difference.

In addition, monitoring system pressures and temperatures is vital for identifying potential issues early. Many professionals overlook these aspects, risking severe complications. Effective maintenance strategies can significantly reduce these risks. Through diligence and attention to detail, one can ensure that working valves function reliably and efficiently.

Understanding the Importance of Valve Maintenance in Industrial Settings

Proper valve maintenance is crucial in industrial settings. According to a report by the American Society of Mechanical Engineers, poor valve maintenance can lead to equipment failure, resulting in significant downtime. In fact, it’s estimated that over 30% of unplanned outages in manufacturing are due to valve issues. Understanding this importance is fundamental to maintaining operational efficiency.

To ensure valves function optimally, regular inspections are necessary. These inspections can reveal wear and tear, corrosion, or buildup. The best practices include checking seals and actuation mechanisms. Don’t ignore minor leaks; they can escalate into bigger problems. Implementing a routine schedule could prevent unexpected costs.

Additionally, training staff on the signs of valve failure can improve maintenance effectiveness. Encourage your team to monitor operational performance closely. They should report even slight anomalies. Proper documentation of any observed issues is vital for historical reference. Sometimes, issues arise from neglect. No one wants to deal with preventable problems.

Identifying Common Issues and Signs of Valve Malfunction

When managing valves, recognizing early signs of malfunction is crucial. One common issue is leakage. If you notice moisture around the valve, it's a warning sign. Manage this by checking seals and connections regularly. A leaking valve can lead to severe damage and high repair costs.

Another sign of malfunction is noise. Unusual sounds during operation may indicate internal problems. Rattling or whistling noises often signal wear or debris inside. Regular maintenance can prevent these issues. Don’t ignore these sounds; they often get worse if left unchecked.

Finally, sticking valves present another challenge. If a valve does not open or close smoothly, check for debris or corrosion. These problems often develop over time and can complicate operations. Keeping a close eye on these signs may save you time and money in the long run.

Tips for Maintaining Your Working Valve Effectively

| Issue | Signs of Malfunction | Maintenance Tips |

|---|---|---|

| Leakage | Visible fluid accumulation around the valve | Check seals and gaskets; replace if worn. |

| Sticking | Valve does not fully open or close | Ensure proper lubrication and inspect for debris. |

| Noise | Unusual sounds during operation | Investigate alignment and wear; repair as needed. |

| Corrosion | Rust or deterioration on valve exterior | Use protective coatings and regular inspection. |

| Pressure Issues | Inconsistent flow or pressure drops | Check operator settings and valve integrity. |

Step-by-Step Guide to Regular Valve Inspection Processes

Regular valve inspection is crucial for maintaining efficiency and safety. Start by checking for leaks. Look for visible signs of wear. A simple visual inspection can reveal many issues. Pay attention to unusual sounds during operation. This could indicate a problem.

Next, clean the valve regularly. Dirt can block movement. Use a soft cloth to wipe down the exterior. For more thorough cleaning, consider proper tools and products. Avoid harsh chemicals that might damage the valve. Always consult guidelines for the best practices in cleaning.

One key tip is to document findings during inspections. Write down any discrepancies. This can help track issues over time. Reflections on these records can lead to better maintenance decisions. Maintain a checklist for valve inspections. It can be easy to miss something without a structured approach. Make note of any parts that seem worn or require replacement.

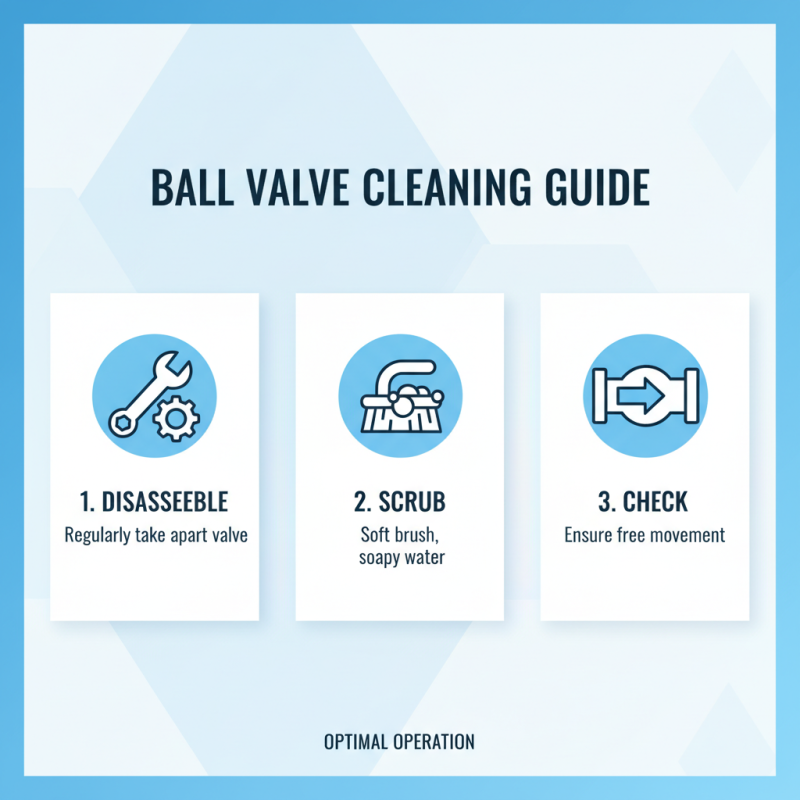

Effective Cleaning Techniques for Different Types of Valves

Cleaning your working valve is crucial for optimal operation. Different types of valves require distinct cleaning techniques. For ball valves, regular disassembly can help remove debris. Use a soft brush and soapy water to scrub the exterior. Ensure the internal parts move freely after cleaning.

For gate valves, a thorough inspection is necessary. Sometimes, the internal surfaces can corrode or accumulate dirt. A mixture of vinegar and water can effectively dissolve buildup. Apply it carefully, and rinse thoroughly to avoid any residue.

Incorporate these tips into your maintenance routine. Regularly scheduled checks can prevent costly repairs. Remember, neglecting minor issues can lead to bigger problems. Take the time to reflect on your process. Are you being consistent? Effective cleaning is not just about technique; it’s also about commitment.

Best Practices for Lubrication and Component Replacement

Lubrication plays a crucial role in maintaining valves. Regular application of the right lubricant helps reduce friction and wear. Remember, not all lubricants are suitable. Check compatibility with your valve materials. Use a silicone-based lubricant for high-temperature environments. A grease that withstands extreme pressures can be crucial too. Apply lubricant sparingly to avoid buildup. Excess grease can attract dirt, complicating maintenance down the line.

Component replacement is equally important. Over time, seals and gaskets wear out, leading to leaks. Inspect these parts frequently. Look for signs of damage or degradation. Delaying replacement can cause unnecessary downtime. Choose high-quality components to ensure longevity. There’s no harm in having a few spare parts on hand. This can save time during an unexpected failure.

Performing these maintenance tasks isn’t always easy. Be prepared to get your hands dirty. Sometimes, valves may require disassembly for proper lubrication. This can be frustrating and time-consuming. However, thoughtful attention can extend the life of your valve. Keep a maintenance log to track when each task was performed. This can help you stay organized and proactive. Regular care and attention will significantly enhance performance.

Related Posts

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Top Benefits of Engineered Valves for Industrial Applications

-

How to Fix a Working Valve Issues Troubleshooting Guide

-

How to Choose the Right Working Valve for Your Project?

(780) 669-9420

(780) 669-9420