Blog

- Home

- Blog

What is Steel Valves and How They Benefit Your Industrial Applications

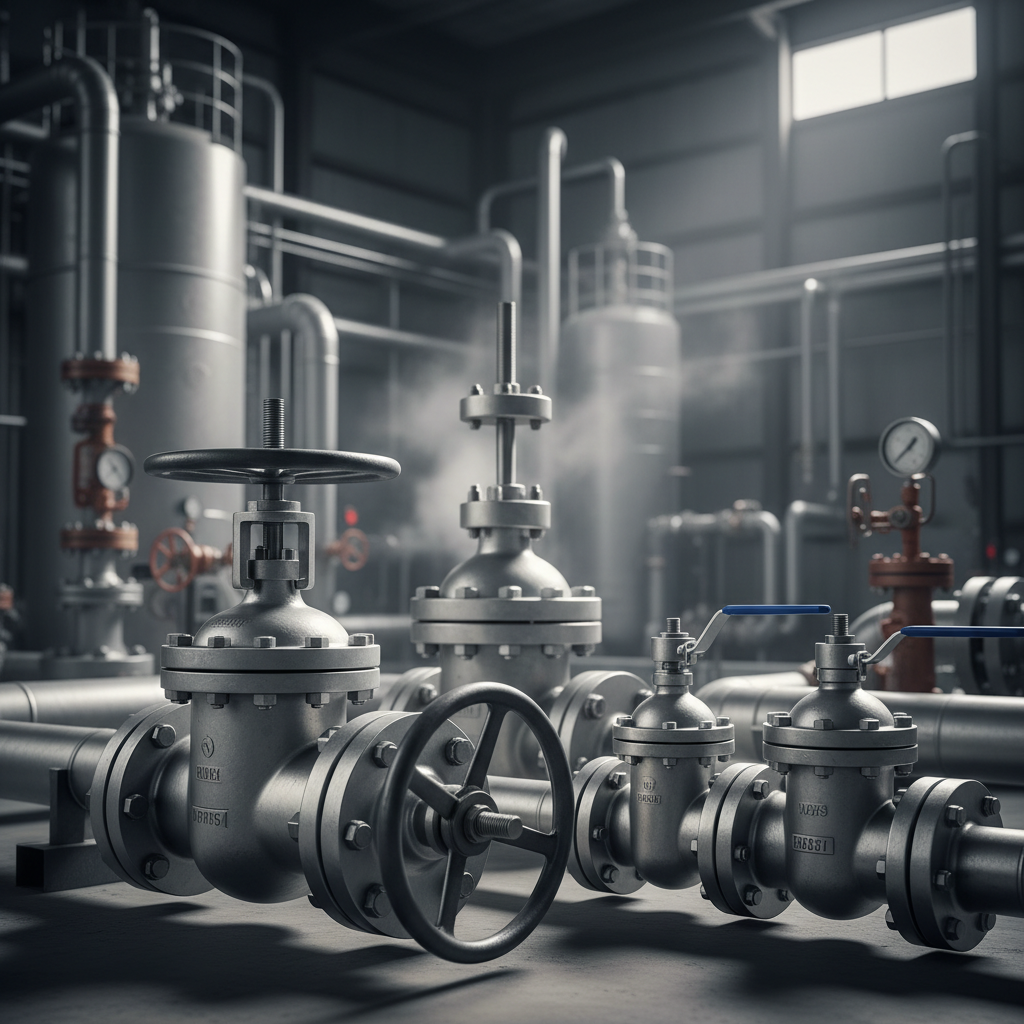

Steel valves are integral components in various industrial applications, serving as essential devices to regulate the flow of liquids and gases. Made from durable steel materials, these valves are designed to withstand high pressure and temperature, making them ideal for even the most demanding environments. Their robust nature not only ensures longevity but also enhances the overall efficiency of industrial processes. Understanding the functionality and advantages of steel valves is crucial for industries aiming to optimize their operations and reduce maintenance costs.

In this exploration of steel valves, we will delve into their various types and how they benefit industrial applications. From gate valves and globe valves to ball valves and check valves, each type serves a specific purpose, catering to different operational needs. Their versatility allows them to be utilized across multiple sectors, including oil and gas, water treatment, and manufacturing. By examining the inherent characteristics and performance metrics of these valves, we can uncover the significant role they play in maintaining system integrity and operational reliability.

Ultimately, this article aims to provide insights into steel valves, highlighting their importance and the advantages they bring to the industrial landscape. By understanding these components better, industries can make informed decisions that enhance productivity and ensure safety in critical processes.

Understanding Steel Valves: Definition and Types for Industrial Use

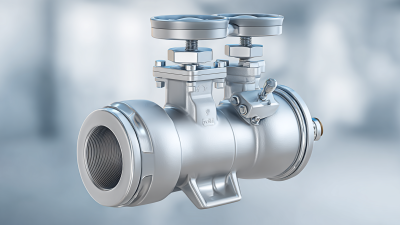

Steel valves are crucial components in various industrial applications, designed to control the flow of fluids and gases. They are primarily made from different grades of steel, offering strength, durability, and resistance to corrosion. Understanding the types of steel valves is essential for optimizing their use in industrial settings. Common types include gate valves, globe valves, ball valves, and check valves, each serving unique functions depending on the requirements of the system.

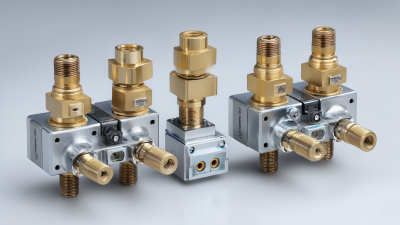

Gate valves are primarily used for on/off control, providing minimal flow resistance when fully open. Globe valves, on the other hand, are ideal for regulating flow due to their design that offers higher pressure drop capabilities. Ball valves are known for their quick operation and are often utilized in applications requiring tight sealing. Lastly, check valves prevent backflow, ensuring fluid flows in the desired direction. By selecting the appropriate type of steel valve, industries can enhance operational efficiency, maintain safety, and reduce maintenance costs.

Key Benefits of Steel Valves in Enhancing Operational Efficiency

Steel valves play a crucial role in various industrial applications, primarily due to their strength, durability, and resistance to corrosion. According to a report by MarketsandMarkets, the global valve market is expected to reach USD 92.3 billion by 2027, growing at a CAGR of 5.3%. This growth showcases the increasing reliance on steel valves in sectors such as oil and gas, water treatment, and chemical processing, where operational efficiency is paramount.

One of the significant benefits of steel valves is their ability to enhance operational efficiency through improved flow control and reduced leakage. A study from the American Society of Mechanical Engineers (ASME) indicates that improper valve selection can lead to energy losses of up to 30% in industrial systems. By utilizing high-quality steel valves, companies can minimize these losses, resulting in lower operational costs. Furthermore, steel valves are known for their longevity, with many industrial applications seeing lifespan extensions of 20-50% compared to other materials. This reliability translates to fewer maintenance stops and enhanced productivity, allowing for continuous operations with minimal downtime.

Key Benefits of Steel Valves in Enhancing Operational Efficiency

Industry Standards and Specifications Influencing Steel Valve Selection

When selecting steel valves for industrial applications, understanding the industry standards and specifications is crucial. The American National Standards Institute (ANSI) provides a set of guidelines that dictate the design, testing, and performance of valves, ensuring they meet stringent safety and reliability requirements. According to a report by the Valve Manufacturers Association of America, adherence to ANSI standards significantly enhances valve performance, particularly in high-pressure environments where even minute failures can lead to catastrophic outcomes.

Another key specification is the American Society for Testing and Materials (ASTM) standards, which address the material properties of steel valves. For instance, ASTM A216 covers the specifications for cast carbon steel valves, ensuring they can withstand various environmental conditions and stresses. The use of valves that comply with ASTM standards can reduce maintenance costs by up to 30%, as stated in a 2021 industry analysis. Furthermore, the International Organization for Standardization (ISO) standards complement these specifications by providing a framework for quality assurance in manufacturing.

These industry standards not only guide the selection process but also influence long-term operational efficiency and sustainability. Companies that prioritize compliance with these specifications often experience improved process control and reduced downtime, contributing to overall productivity and cost savings.

Cost Analysis: Long-term Savings with Steel Valves in Industrial Setups

When considering industrial applications, the choice of materials for components like valves can significantly affect both operational efficiency and long-term expenditure. Steel valves, known for their durability and resistance to harsh environments, offer substantial cost benefits over time. Their robust construction leads to a longer lifespan, reducing the frequency of replacements and maintenance interventions. This durability translates into decreased downtime, allowing operations to run smoothly and efficiently, ultimately saving money.

In addition to their longevity, steel valves maintain a high performance under extreme conditions, such as high pressure and temperature, which is often required in industrial settings. This resilience reduces the likelihood of failures that could lead to costly repairs and losses in productivity. Furthermore, the reduced need for frequent replacements means less waste and lower overall material costs. In the long run, investing in steel valves may result in significant savings, making them a smart choice for industries looking to optimize their operations while minimizing expenses.

Future Trends in Steel Valve Technology and Their Impact on Industries

The future of steel valve technology is poised for significant advancements, driven by the increasing demand for efficiency, durability, and sustainability across various industries. One of the most notable trends is the integration of smart technology into valve systems. This includes the adoption of IoT (Internet of Things) capabilities, which allow for real-time monitoring and control of valve operations. By harnessing data analytics, industries can predict maintenance needs, optimize performance, and enhance overall system reliability, ultimately reducing downtime and operational costs.

Additionally, the development of advanced materials and coatings is transforming steel valve production. Manufacturers are focusing on enhancing resistance to corrosion and wear, which is crucial in industries such as oil and gas, water treatment, and chemical processing. The introduction of lightweight, high-strength alloys further contributes to improved performance and longevity, addressing both environmental concerns and the need for cost-effective solutions. As these innovations continue to evolve, the impact on industries will be profound, leading to more efficient processes and a shift towards sustainable practices in industrial applications.

What is Steel Valves and How They Benefit Your Industrial Applications - Future Trends in Steel Valve Technology and Their Impact on Industries

| Dimension | Data |

|---|---|

| Material Type | Stainless Steel, Carbon Steel, Alloy Steel |

| Common Applications | Oil & Gas, Water Treatment, Chemical Processing |

| Pressure Ratings | 150 - 1500 PSI |

| Temperature Range | -50°F to 1000°F |

| Recent Trends | Smart Valves, Eco-friendly Materials, Enhanced Durability |

| Future Impacts | Increased Efficiency, Reduced Energy Costs, Improved Safety |

Related Posts

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

(780) 669-9420

(780) 669-9420