Blog

- Home

- Blog

What is a Single Valve and How Does it Work?

In the world of fluid control, the concept of a "single valve" plays a crucial role. A well-known expert in this field, Dr. Alice Harper, once stated, "The simplicity of a single valve design often belies its complexity." This statement encapsulates the dual nature of single valves; they are straightforward yet sophisticated in their functionality.

Single valves operate by regulating the flow of liquids or gases in various systems. Their design typically features one inlet and one outlet. This simplicity allows for efficient and effective control. However, the true challenge lies in the precision required for their operation. Miscalculations or improper installations can lead to significant inefficiencies.

Consider a irrigation system that relies on a single valve to distribute water. If that valve fails, the consequences can be severe. Fields may go dry, crops could wilt, and the entire agricultural yield suffers. Such scenarios highlight the essential nature of a single valve and the necessity for meticulous attention in its application. Understanding their mechanics is more than theoretical; it involves a deep awareness of the potential pitfalls that come with their use.

What is a Single Valve?

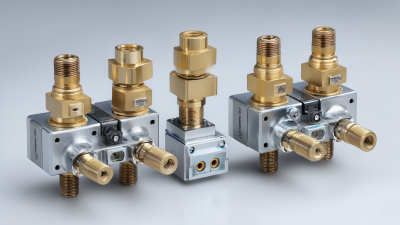

A single valve is a crucial component found in many systems, particularly in plumbing and gas applications. It controls the flow of fluids or gases through a pipe. Essentially, it allows or prohibits passage based on its position. This simplicity makes it widely used in various fields, from household systems to industrial setups.

The working principle of a single valve is straightforward. When the valve is open, fluid can flow freely. When closed, the flow is stopped entirely. It may be operated manually or automatically. In some cases, the design includes a spring mechanism that provides resistance, helping to maintain the valve's position. This simplicity often leads to reliability, but there are considerations.

Tips: Regular maintenance is essential. Check for leaks or erosion regularly. Small issues can escalate quickly. Ensure that the valve operates smoothly without sticking. Be mindful of any unusual noises during operation. These can signal underlying problems that need attention.

Many people overlook the importance of understanding their system's components. Knowing how a single valve functions can prevent costly repairs. If something feels off, it's worth investigating. Pay attention to your valve's performance, as it directly impacts system efficiency.

Single Valve Performance Analysis

This bar chart illustrates the performance metrics of a single valve, showcasing its flow rate, pressure drop, and operating temperature. These factors are crucial for assessing valve efficiency and operational suitability in various applications.

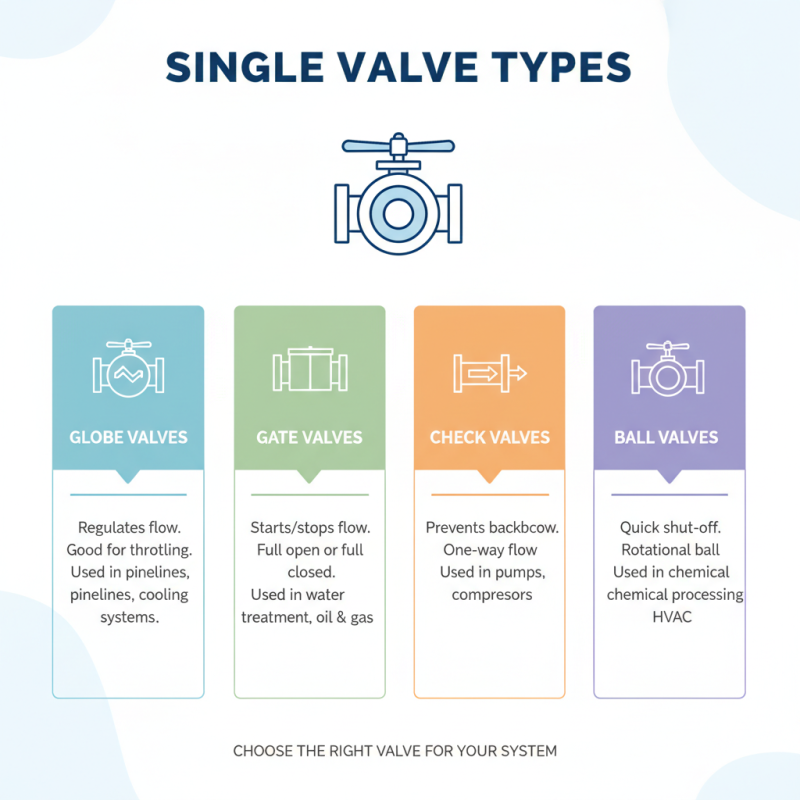

Types of Single Valves Used in Various Applications

Single valves are essential components in many systems. They control the flow of liquids or gases. These valves can be classified into different types based on their applications. Understanding these types can help in choosing the right valve for your needs.

One common type is the globe valve. This valve is great for throttling flow. It allows precise adjustments. However, it may cause pressure drops. Another type is the ball valve. It provides a quick shut-off. This valve operates with a simple quarter turn. It's fast and effective but may not be ideal for throttling purposes.

Check valves are also widely used. They prevent backflow in a system. This is crucial in many applications, such as water and wastewater treatment. But they can be prone to wear over time. Each type has its strengths and weaknesses. Choosing the right single valve can enhance efficiency in various operations. However, careful consideration is necessary to avoid potential issues.

How a Single Valve Operates Mechanically

A single valve is a critical component in various mechanical systems. Its primary function is to control the flow of fluids, often in pipes or tanks. When pressure is applied, the valve opens, allowing liquid or gas to pass through. Mechanical operation varies by design, but the core principle remains the same.

Understanding how a single valve operates mechanically is essential for maintenance. The valve typically contains a stem, disc, and seat. When the stem is turned, the disc moves, either blocking or allowing flow. This simple movement can significantly impact system efficiency. Data indicates that proper valve maintenance can enhance system lifespan by up to 30%.

Here are some tips for maintaining single valves effectively:

1. Regularly inspect for leaks or wear.

2. Clean the valve components to prevent clogging.

3. Ensure proper alignment of the stem and disc.

Single valves can sometimes fail unexpectedly, leading to increased downtime. Operators should remain vigilant and proactive in identifying potential issues. Often, taking the time to perform routine checks can prevent larger problems down the road.

Advantages of Using a Single Valve System

A single valve system offers several key advantages that make it a popular choice in various applications. This type of system simplifies the management of fluids. With only one valve to control, users can minimize the complexity of their setup. It reduces the number of failure points, making maintenance easier and less costly.

Another advantage is the compact design. A single valve requires less space than multiple-valve systems. This is crucial in tight environments, like small industrial facilities or residential setups. Less space can result in lower installation costs and greater design flexibility.

However, there are some considerations. A single valve may not provide the same level of control as a more complex system. Users might have limited options for adjusting flow rates. This could lead to inefficiencies in certain scenarios. Balancing ease of use with the need for precise control requires careful thought. Users should evaluate their specific needs thoroughly.

Common Applications of Single Valves in Industries

Single valves are essential components in various industries. They control fluid flow in systems ranging from water supply to chemical processing. Many industries rely on them for efficiency and safety.

In water treatment facilities, single valves help manage pressurized water. They ensure a steady flow during filtering processes. In manufacturing, these valves regulate steam in heating systems. This is crucial for temperature control. Food processing also integrates single valves to maintain hygiene. They help prevent contamination in liquids and gases, ensuring product safety.

Tips for Choosing a Single Valve: Always consider the pressure ratings. Compatibility with the fluid is also vital. Inspect materials used in the valve body. They should withstand chemical corrosivity.

Beyond these applications, single valves face challenges. Maintenance is often overlooked. Regular checks can prevent leaks and failures. Consider training for staff on proper handling. It helps avoid mistakes during operation.

Related Posts

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

10 Essential Tips for Maintaining Your Working Valve Efficiency?

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

(780) 669-9420

(780) 669-9420