Blog

- Home

- Blog

Top Insights on Through Valve Technology for 2025 and Beyond

As we look toward 2025 and beyond, the landscape of valve technology is undergoing significant transformation, particularly with the advent of through valve innovations. This technology is not only reshaping traditional methods of controlling fluid dynamics but also enhancing efficiency and reliability across various industries. The through valve mechanism provides a seamless flow path that minimizes turbulence and pressure drops, enabling systems to operate more smoothly and effectively.

The advancements in through valve technology promise to drive improvements in performance metrics, reduce maintenance costs, and extend the life of critical infrastructure. By integrating smart technologies and materials with enhanced durability, these valves are set to meet the rising demands for sustainability and operational excellence. As industries continue to innovate, understanding the implications of through valve advancements will be crucial for engineers, manufacturers, and stakeholders alike. They will need to adapt to these changes to leverage the benefits that come with improved fluid control solutions in an increasingly competitive marketplace.

Advancements in Through Valve Technology: A 2025 Perspective

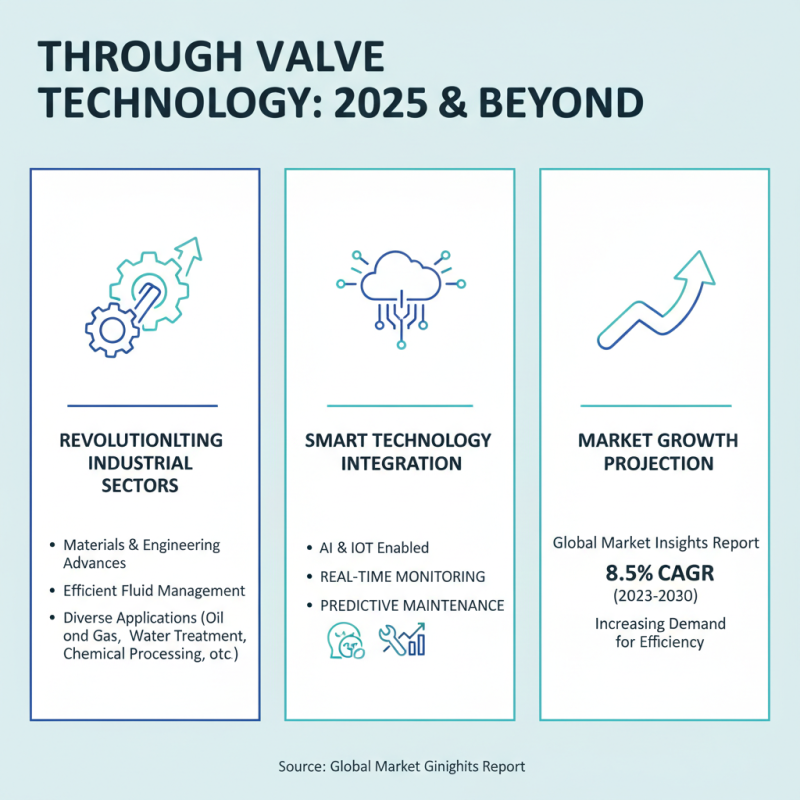

Through valve technology is poised to revolutionize various industrial sectors in 2025 and beyond, driven by continued advancements in materials and engineering practices. The integration of smart technologies, such as artificial intelligence and the Internet of Things (IoT), is enhancing the capabilities of through valves by enabling real-time monitoring and predictive maintenance. According to a recent report by Global Market Insights, the market for through valve technology is expected to grow at a CAGR of 8.5% from 2023 to 2030, reflecting the increasing demand for efficient fluid management solutions.

As industries prioritize sustainability, through valve technology is increasingly designed with eco-friendly materials that reduce environmental impact while maintaining performance. This not only helps in compliance with stricter regulations but also reduces life-cycle costs. Data from the International Energy Agency indicates that optimizing fluid systems via advanced through valve technologies can result in energy savings of up to 20%, making it a critical component in achieving sustainability goals.

Tips: When considering through valve technology for your operations, assess the compatibility of materials with the fluids being managed to ensure durability and efficiency. Additionally, integrating IoT devices can provide significant insights into valve performance, allowing for optimized operational strategies. Stay updated on industry reports to benchmarks your practices against emerging trends and innovations.

Key Industries Impacted by Through Valve Technology Innovations

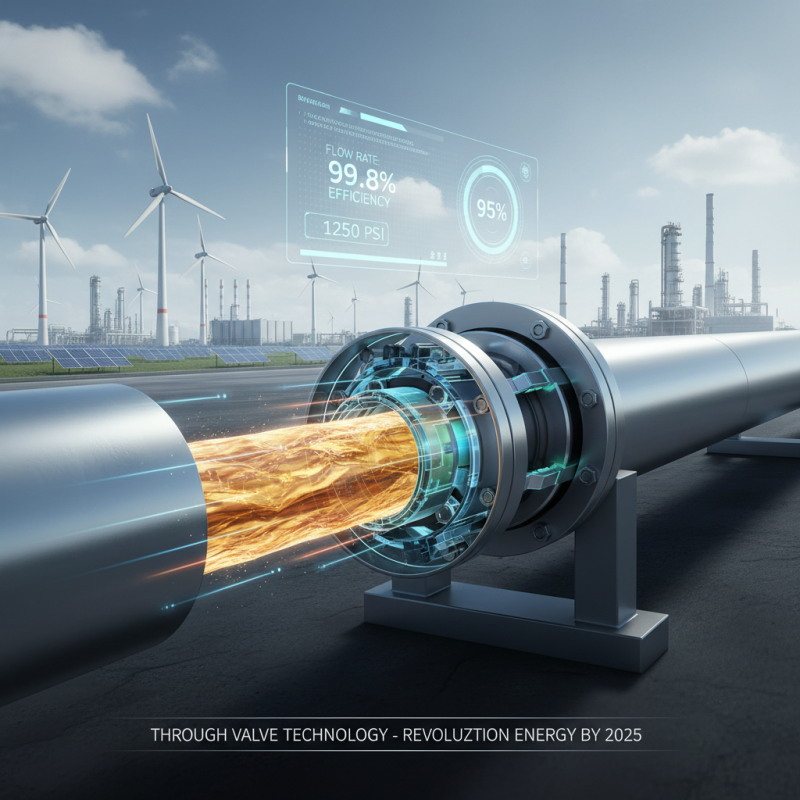

Through valve technology is poised to revolutionize several key industries by 2025 and beyond. One of the primary sectors benefiting from these innovations is the energy industry, particularly in oil and gas. The ability to control flow and pressure more efficiently will not only enhance operational safety but also reduce environmental impact. Advanced through valve systems can help in minimizing leaks and emissions, allowing companies to adopt cleaner practices while maintaining productivity.

Another significant area impacted is the manufacturing sector. As industries strive for greater automation and efficiency, through valve technology will streamline processes and enhance equipment reliability. With intelligent control mechanisms, manufacturers can achieve better precision in their operations, leading to increased output and reduced downtime. Furthermore, the integration of smart through valve systems will facilitate real-time monitoring and predictive maintenance, enabling companies to respond swiftly to potential issues and optimize their production lines. The advances in this technology will contribute significantly to more sustainable manufacturing practices, promoting resource conservation and efficiency.

Potential Environmental Benefits of Modern Through Valve Systems

The modern advancements in through valve technology are poised to offer significant environmental benefits, particularly as we move toward more sustainable practices in various industries. As reported in a recent study by the Environmental Protection Agency, the adoption of high-efficiency through valve systems can reduce greenhouse gas emissions by up to 30% compared to traditional systems. This is primarily achieved through improved flow dynamics and reduced energy consumption, allowing for more efficient operation in applications ranging from water treatment to industrial processes.

Additionally, the integration of smart technologies into through valve systems enables real-time monitoring and control, which is crucial for minimizing waste. According to a report by the International Energy Agency, intelligent valve management systems can decrease water loss in distribution systems by approximately 25%, resulting in significant conservation of one of our planet’s most vital resources. Moreover, these systems often require less maintenance and fewer replacement parts, leading to reduced material waste and a smaller environmental footprint over their lifecycle.

As industries continue to face pressure to adopt greener practices, the environmental implications of modern through valve technology will likely play a pivotal role in shaping operational strategies for the future. Emphasizing sustainability not only enhances compliance with environmental regulations but also reflects a commitment to corporate social responsibility, aligning with consumer expectations for eco-friendly practices in today’s market.

Top Insights on Through Valve Technology for 2025 and Beyond - Potential Environmental Benefits of Modern Through Valve Systems

| Insight Area | Description | Environmental Benefit | Projected Impact by 2025 |

|---|---|---|---|

| Energy Efficiency | Through valve systems improving energy consumption in fluid transport. | Reduction in carbon footprint. | Up to 30% energy savings across industries. |

| Emissions Control | Integration of smart technologies for real-time monitoring. | Lower air and water emissions. | Estimated reduction of 40% pollutant emissions. |

| Sustainability | Durable materials reducing the need for frequent replacements. | Increased lifecycle and waste reduction. | Lifecycle extension of up to 50% for components. |

| Maintenance Reduction | Self-diagnostics and predictive maintenance features. | Less resource consumption for maintenance. | Reduction in maintenance costs by 20%. |

| Water Conservation | Advanced flow control mechanisms for precise usage. | Significant reduction in water wastage. | Potential savings of millions of gallons per year. |

Challenges and Solutions in Implementing Advanced Through Valve Technology

The advent of advanced through valve technology presents a unique set of challenges that industry stakeholders must navigate as they prepare for 2025 and beyond. One significant hurdle is the integration of these technologies into existing systems. Many facilities operate with legacy infrastructure that may not be compatible with the latest innovations. Upgrading pipelines and control systems can be costly and time-consuming, requiring thorough planning and investment. Additionally, there is often resistance to change within organizations, as employees may be apprehensive about adopting new technologies. Effective training and communication strategies will be essential to ease this transition and foster acceptance.

Another challenge lies in the regulatory landscape. As technology evolves, so too do the regulations that govern it. Keeping abreast of changes in legislation and ensuring compliance can be daunting. Companies must also consider environmental implications, as there is a growing demand for sustainable practices in the industry. Developing through valve solutions that minimize environmental impact while maintaining efficiency will be crucial. Collaborating with regulatory bodies and engaging in proactive dialogue can help organizations anticipate and address these challenges, ensuring smoother implementation of through valve technology in the coming years.

Future Trends: What to Expect in Through Valve Technology by 2030

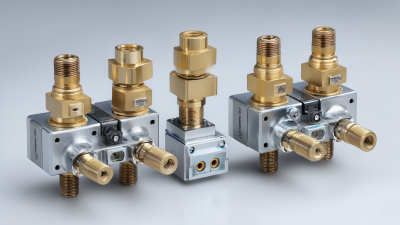

Through valve technology is anticipated to undergo significant evolution by 2030, driven by advancements in materials science and automation. As industries increasingly prioritize efficiency and sustainability, new lightweight yet durable materials will enhance valve performance, providing greater resistance to corrosion and wear. This will not only extend the lifespan of the valves but also reduce maintenance costs, making operations more economical.

Moreover, the integration of smart technology into through valves will revolutionize monitoring and control processes. Sensors and IoT capabilities will enable real-time data collection, allowing for predictive maintenance and efficient lifecycle management. As industries adopt more intelligent systems, expect a shift towards automated control mechanisms that facilitate adaptive responses to varying operational conditions. This trend will empower organizations to optimize their processes, ensuring better resource management and minimizing downtime. The decade ahead promises exciting developments that will ultimately enhance the reliability and functionality of through valve systems, shaping a more innovative industrial landscape.

Through Valve Technology Trends: 2025 to 2030

This chart illustrates the projected market growth percentage of through valve technology between 2025 and 2030. The data indicates a steady increase in market adoption and advancement over this period, highlighting the importance of this technology in various industries.

Related Posts

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Top 10 Tips for Choosing the Right Valve Steel for Your Projects

(780) 669-9420

(780) 669-9420