Blog

- Home

- Blog

Exploring the Future: Top Valve Engineering Innovations of 2025

In the ever-evolving landscape of valve engineering, the year 2025 promises to bring groundbreaking innovations that will redefine industry standards and operational efficiencies. According to Dr. Emily Carter, a leading expert in valve engineering, “The future of valve technology lies in the integration of smart materials and real-time data analytics, paving the way for more adaptive and responsive systems.” Her insights underscore the significance of technological advancements that harness artificial intelligence, automation, and sustainable practices within the valve engineering sector.

As we delve into the top innovations set to shape the future of valve engineering, it becomes evident that the convergence of these technologies is not merely a trend but a necessity for enhancing performance and safety in various industrial applications. From predictive maintenance to enhanced sealing mechanisms, these innovations hold the potential to streamline operations and reduce downtime, ultimately leading to significant cost savings for businesses.

This exploration not only highlights the cutting-edge developments on the horizon but also emphasizes the critical role of valve engineering in maintaining the integrity and efficiency of complex systems worldwide. As we look ahead, the commitment to innovation within this field serves not only the industry but also contributes to broader environmental and economic sustainability goals.

Emergence of Smart Valves in Industrial Automation

The industrial landscape is on the brink of a significant transformation with the emergence of smart valves. These advanced devices are not just mechanical components; they incorporate sophisticated sensors and communication technologies that facilitate real-time data exchange. By integrating IoT capabilities, smart valves can monitor system performance, detect faults, and optimize flow control automatically. This synergy enhances operational efficiency and reduces the likelihood of costly downtime, leveraging predictive maintenance strategies that keep industrial processes running smoothly.

Moreover, the transition to smart valves is bolstered by the rise of automation in manufacturing and process industries. As facilities strive for higher levels of productivity and reliability, intelligent valve systems can adjust to fluctuating conditions autonomously, enabling a more responsive and flexible operation. With machine learning algorithms, these innovations can learn from historical data, leading to improved decision-making and energy savings. This shift not only promotes sustainability but also aligns with the broader trend towards digital transformation in industrial environments, setting the stage for smarter, more connected operations in 2025 and beyond.

Exploring the Future: Smart Valve Innovations in Industrial Automation (2025)

This chart illustrates the anticipated growth in the adoption of various smart valve technologies in industrial automation by 2025. The data showcases the increasing significance of each technology level, indicating a clear trend toward higher adoption rates for advanced smart valves.

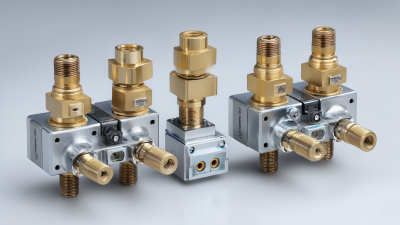

Advancements in Valve Materials for Enhanced Durability

The future of valve engineering is poised for significant transformations, especially in the realm of materials innovation aimed at enhancing durability. According to a recent report by the Valve Manufacturers Association, the global valve market is expected to exceed $90 billion by 2025, driven in large part by advancements in material science. Innovations such as the development of advanced ceramics and composites are emerging, offering improved wear resistance and corrosion protection, which are critical for industries like oil and gas and water treatment. By leveraging these new materials, manufacturers can produce valves that not only perform better under extreme conditions but also have a longer operational lifespan, reducing maintenance costs and downtime.

Furthermore, a study by Market Research Future indicates that the demand for durable valves will increase by approximately 5% annually, highlighting the need for industries to adopt innovative materials. The introduction of high-performance polymers and metal alloys, which can withstand extreme temperatures and pressures, is crucial in this landscape. These materials provide enhanced mechanical properties, making them ideal for applications in chemical processing and energy generation. As engineers explore these options, they are also focused on sustainability, leading to the development of eco-friendly valve materials that minimize environmental impact while maximizing efficiency and longevity. This next generation of valve engineering will not only revolutionize industry standards but also ensure that operational efficiency meets the demands of a rapidly evolving global market.

Integration of IoT Technology in Valve Management Systems

The integration of IoT technology in valve management systems is poised to revolutionize the industry by 2025. As the demand for automation grows, the market for smart valves is expected to reach $10 billion, according to a report by MarketsandMarkets. This increase is driven by the need for more efficient fluid management, reduced operational costs, and enhanced safety measures in various industrial sectors, including oil and gas, water management, and manufacturing.

Implementing IoT in valve management allows for real-time monitoring and predictive maintenance, which significantly reduces downtime and extends the life cycle of valve systems. By utilizing sensors and cloud computing, operators can receive instantaneous alerts regarding valve performance, detect leaks, and optimize flow control based on real-time data analytics. A report from Grand View Research forecasts that the global IoT in the manufacturing sector will reach approximately $273 billion by 2026, highlighting the critical role of connected devices in enhancing operational efficiencies.

Moreover, the integration of advanced data analytics facilitates better decision-making, offering insights into usage patterns and resource allocation. As industries increasingly embrace digital transformation, the adoption of IoT-enabled valve management systems will be crucial in streamlining operations and meeting regulatory requirements. The trend indicates a future where traditional valve management systems evolve into sophisticated, interconnected platforms that contribute significantly to operational flexibility and resilience.

Sustainability Practices in Valve Engineering Innovations

The future of valve engineering in 2025 is poised to embrace sustainability as a core principle driving innovation. As industries worldwide prioritize environmentally friendly practices, valve engineering is adapting to meet these demands by developing materials and designs that minimize environmental impact. Advanced composite materials and bio-based alternatives are increasingly being integrated into valve manufacturing processes. These innovations not only reduce the carbon footprint but also enhance the durability and performance of valves under various operating conditions.

Moreover, the role of automation and smart technology in valve systems is becoming critical for promoting sustainability. Intelligent valves equipped with sensors and IoT capabilities can monitor and optimize flow rates and pressure, enabling energy-efficient operations. This real-time data collection allows industries to detect leaks or inefficiencies promptly, leading to significant resource conservation. Integrating renewable energy sources into valve operations further supports sustainable engineering goals, showcasing a commitment to reducing reliance on non-renewable resources in valve applications.

Future-Proofing Valves: Adaptive Designs for Changing Environments

The evolving landscape of valve engineering is increasingly characterized by innovations aimed at future-proofing designs for diverse and changing environments. As industries face heightened demands for efficiency and adaptability, the focus has shifted to creating valves capable of reacting dynamically to varying conditions. According to a recent industry report by Research and Markets, the global valve market is expected to grow from $60 billion in 2022 to nearly $90 billion by 2025, underscoring the critical need for adaptable solutions in valve design.

Adaptive valve systems integrate advanced technologies such as IoT and AI, allowing for real-time monitoring and control. These innovations facilitate predictive maintenance and enhance operational efficiency, ultimately reducing downtime and maintenance costs. A study from the Valve Manufacturers Association indicates that by implementing adaptive designs, companies could achieve up to a 30% reduction in maintenance expenses, as these systems can self-adjust to optimize performance under varying pressures and temperatures.

The implementation of such adaptive valves is essential for industries like oil and gas, water treatment, and chemical processing, where environmental conditions can shift rapidly. Moreover, with growing regulatory pressures for sustainability and safety, the development of materials that can withstand harsher environments also plays a pivotal role. Enhanced corrosion resistance and improved sealing technologies are key areas of focus, enabling valves to operate effectively in more demanding circumstances while ensuring compliance with stringent environmental regulations.

Related Posts

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

(780) 669-9420

(780) 669-9420