Blog

- Home

- Blog

How to Fix a Working Valve Issues Troubleshooting Guide

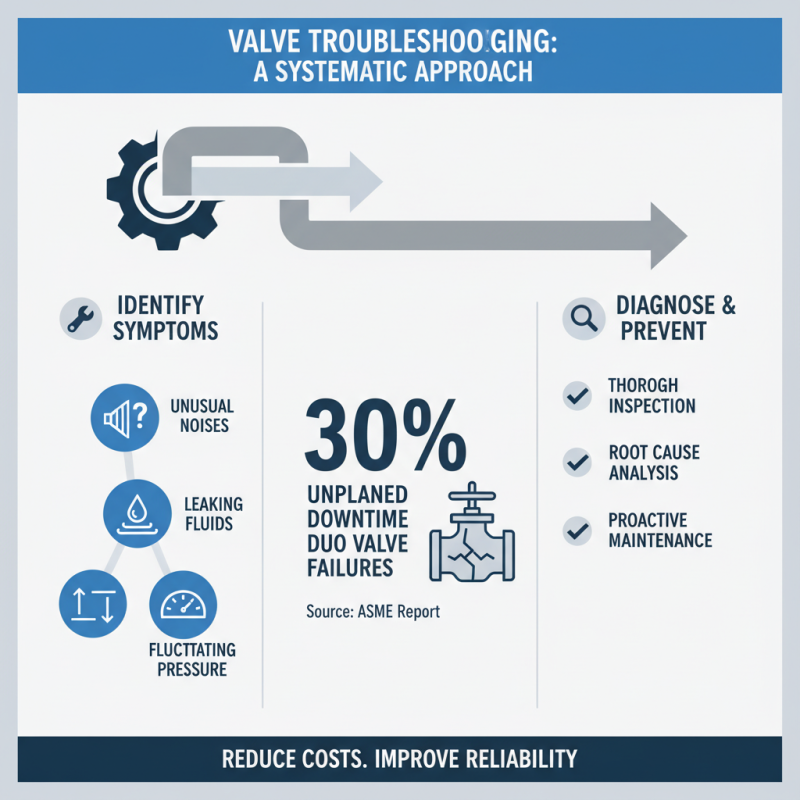

In the realm of industrial operations, the reliability of equipment is crucial, and among these, the functionality of working valves stands at the forefront. Valves are essential components responsible for regulating fluid flow in various systems, and their performance directly impacts the efficiency and safety of operations. According to a report from the National Institute of Standards and Technology, failures in valve operations can account for up to 30% of all maintenance issues in industrial settings. This statistic underscores the significance of addressing working valve problems promptly to avoid costly downtime and ensure seamless processes.

Identifying and troubleshooting working valve issues can often be challenging due to the complexity of systems involved. Factors such as environmental conditions, wear and tear over time, and improper installation can contribute to valve malfunction. The American Society of Mechanical Engineers notes that proactive maintenance and regular inspections can reduce valve failures by as much as 40%. Therefore, understanding how to effectively diagnose and fix valve issues is not only a matter of operational integrity but also a vital aspect of ensuring long-term cost efficiency in plant management. In this troubleshooting guide, we will explore systematic approaches to identify, evaluate, and resolve common working valve anomalies, empowering operators to sustain optimal functionality in their systems.

Understanding the Basics of Valve Functionality and Common Issues

Understanding the basics of valve functionality is crucial for troubleshooting common issues that may arise in various systems. Valves are essential components in controlling fluid flow, and their proper operation is vital for maintaining efficiency and safety. Most commonly, valves operate through a mechanism that opens or closes to regulate the flow of liquids or gases.

Familiarity with different valve types, including gate, globe, and ball valves, helps in recognizing their unique functionalities and the potential problems they may encounter.

Common issues with valves often stem from mechanical wear, build-up of debris, or improper installation. Symptoms such as leaks, erratic flow, or failure to open or close can indicate specific problems. For instance, a leaking valve may require inspecting seals and gaskets for wear or damage, while a valve that won’t open can result from debris blocking the mechanism.

Understanding these fundamental characteristics and issues not only allows for effective troubleshooting but also aids in preventive maintenance, ensuring the longevity and reliability of the entire system.

Identifying Symptoms of Valve Malfunctions in Various Systems

When dealing with valve malfunctions, identifying symptoms is crucial for efficient troubleshooting. Various systems utilize valves in numerous applications, and recognizing the signs of a malfunction can prevent further complications. Common symptoms include unusual noises such as hissing or rattling, which may indicate leakage or internal wear. Additionally, a noticeable drop in system pressure may point to a valve that is not sealing properly, allowing fluid or gas to escape.

Another critical symptom to observe is irregular flow rates. If a valve is partially open or stuck, it can disrupt the flow in a piping system, leading to inconsistent performance. Temperature fluctuations in systems relying on valves for thermal regulation can also signal underlying issues. In some cases, visible leaks around the valve body might be the most apparent sign of malfunction, demanding immediate attention to prevent damage to the system. By paying close attention to these symptoms, operators can quickly diagnose valve issues and implement appropriate repairs.

How to Fix a Working Valve Issues Troubleshooting Guide

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Leaking Valve | Worn out seal or gasket | Replace seals or gaskets |

| Sticking Valve | Corrosion or debris build-up | Clean and lubricate the valve |

| No Response | Electrical failure or signal loss | Check electrical connections and signals |

| Unusual Noises | Loose components or misalignment | Tighten and align components |

| Slow Operation | Insufficient pressure or blockages | Check pressure levels and clear blockages |

| Erratic Function | Electrical interference or control issues | Inspect control system and eliminate interference |

Step-by-Step Troubleshooting Procedures for Valve Problems

When addressing valve problems, a systematic approach is essential for effective troubleshooting. Begin by identifying the symptoms of the issue. Common signs may include unusual noises, leaking fluids, or fluctuating pressure levels. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of unplanned downtime in industrial operations can be attributed to valve failures. This statistic underscores the importance of a thorough diagnosis in preventing costly interruptions.

Once symptoms are noted, proceed with a step-by-step examination of the valve components. Start by checking for mechanical obstructions or damage that might hinder the valve's operation. Engaging in regular inspections as suggested by the International Organization for Standardization (ISO) can reduce failure rates significantly, with some industries reporting up to a 50% decrease in malfunction occurrences when comprehensive maintenance schedules are followed. After mechanical issues are assessed, evaluate the actuator and control systems to ensure signals and movements are functioning correctly.

In conclusion, each step in the troubleshooting process should be documented, as maintaining a detailed maintenance history can help identify patterns over time, leading to more effective preventive measures. By following these procedures, industries can enhance reliability and extend the lifespan of their valve systems, ultimately resulting in increased operational efficiency.

Essential Tools and Techniques for Effective Valve Repair

When dealing with valve issues, having the right tools and techniques is fundamental for effective repair and troubleshooting. Essential tools include valve wrenches, pressure gauges, and torque tools. According to industry reports, utilizing specialized torque wrenches can reduce the risk of valve failure by up to 30%, ensuring that seals are secured without damaging components. Additionally, pressure gauges play a critical role in identifying leaks and assessing the health of a valve system.

Tips for effective valve repair include conducting regular maintenance checks to identify wear and tear before they develop into major issues. Documentation of maintenance history is crucial; a study shows that companies with organized maintenance logs report 50% fewer valve issues compared to those without. Furthermore, employing techniques such as ultrasonic testing can detect internal valve issues that are not visible externally, adding an extra layer of reliability to maintenance practices.

For troubleshooting, start with identifying the symptoms, whether it's leakage, failure to open, or erratic performance. Once symptoms are noted, proper isolation of the valve from the system is key to safely carrying out repairs. Utilizing a systematic approach based on data and observations not only expedites the troubleshooting process but significantly enhances the chances of a successful repair.

Valve Repair Effectiveness by Technique

Preventative Maintenance Tips to Avoid Future Valve Issues

Preventative maintenance is essential for ensuring that valves in various applications operate effectively and avoid troublesome issues in the future. Regular inspections should be part of your maintenance routine, allowing you to identify early signs of wear or damage. Checking for leaks, unusual noises, and pressure fluctuations can help detect problems before they escalate. Additionally, ensure that the working environment is clean, as debris and contaminants can lead to malfunctioning valves.

Lubrication plays a significant role in the longevity of valve components. Ensuring that moving parts are well-lubricated can prevent rust and reduce friction, contributing to smoother operation. It’s also important to follow manufacturer guidelines for maintenance schedules and recommended practices specific to the type of valve in use. Conducting periodic tests of the valve’s function, including pressure and flow rate evaluations, will help maintain optimal performance and extend the life of the equipment. By actively engaging in these preventative measures, you can significantly reduce the likelihood of valve-related issues arising in the future.

Related Posts

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

2025 Top Valve Applications You Need to Know for Future Innovations

(780) 669-9420

(780) 669-9420