Blog

- Home

- Blog

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

In today's fast-paced industrial landscape, optimizing operational efficiency has never been more crucial. Companies are constantly seeking innovative strategies to enhance productivity and reduce costs. One of the most effective approaches lies in the implementation of engineered solutions. These tailored strategies not only address specific operational challenges but also drive significant improvements in performance. By harnessing advanced technologies and methodologies, businesses can achieve notable efficiency gains, often targeting an increase of up to 30%.

Engineered solutions encompass a range of techniques, from automation integration to process re-engineering, each designed to streamline workflows and eliminate bottlenecks. As industries continue to evolve, the demand for customized solutions that can adapt to unique operational needs grows. In this context, understanding how to effectively leverage engineered solutions becomes paramount for organizations aiming to stay competitive and responsive to market demands. This article will explore key tips for implementing these solutions effectively, providing insights and practical strategies to boost efficiency in industrial operations significantly.

Maximizing Asset Utilization Through Smart Data Integration

In today's competitive industrial landscape, maximizing asset utilization is critical for enhancing operational efficiency. According to a report from the International Society of Automation, organizations can achieve an increase in equipment effectiveness of up to 30% by implementing data integration strategies. By harnessing smart data integration, industries can seamlessly connect disparate systems, thus enabling real-time visibility into asset performance and optimizing maintenance schedules. This proactive approach minimizes downtime and enhances productivity across all operations.

Moreover, a study from McKinsey & Company highlights that companies leveraging advanced analytics and integrated data environments can reduce operational costs by up to 25%. By utilizing predictive maintenance and IoT-enabled sensors, businesses can transform their operations, ensuring assets are utilized to their fullest potential. This strategic alignment of technology and data not only drives efficiency but also provides a pathway to greater innovation and responsiveness in an ever-evolving market.

Implementing Predictive Maintenance for Operational Downtime Reduction

In the realm of industrial operations, implementing predictive maintenance has emerged as a pivotal strategy for reducing operational downtime. According to a report by McKinsey & Company, organizations that adopt predictive maintenance techniques can achieve up to a 30% reduction in operational costs, directly correlating with enhanced efficiency. This proactive approach not only minimizes unplanned outages but also extends the lifespan of equipment, ultimately leading to significant savings.

To successfully implement predictive maintenance, companies should consider integrated data analytics and machine learning models to identify potential failures before they occur. This requires collecting real-time data from machinery and utilizing advanced algorithms to interpret this information effectively. Tip: Regularly update and calibrate your sensors and data-gathering devices to ensure accuracy and reliability of your predictive models.

Moreover, establishing a culture of continuous improvement and employee training plays a vital role in maximizing the benefits of predictive maintenance. By investing in staff development, companies can enhance skill sets required for effective maintenance strategies. Tip: Encourage cross-department collaboration to facilitate knowledge sharing and innovate maintenance solutions across the organization. As seen in various case studies, these measures have proven to lead to more streamlined operations and a notable boost in productivity across industries.

Streamlining Workflows with Automation and Real-Time Analytics

In today's fast-paced industrial landscape, the integration of automation and real-time analytics is essential for streamlining workflows and enhancing efficiency. By adopting automated processes, businesses can reduce manual labor and minimize human error, leading to faster production cycles and improved output quality. Automation tools can take over repetitive tasks, allowing employees to focus on higher-value activities that require critical thinking and problem-solving skills, ultimately contributing to increased productivity.

Real-time analytics plays a crucial role in monitoring operations and providing actionable insights. With the ability to analyze data as it happens, companies can make informed decisions swiftly, adapt to changing conditions, and identify potential bottlenecks before they escalate. This immediate feedback loop empowers managers to optimize resource allocation and enhance overall operational efficiency. By combining automation with real-time analytics, organizations can not only boost efficiency by 30% but also position themselves to respond proactively to market demands, ensuring sustained growth in a competitive environment.

Enhancing Team Collaboration Using Digital Communication Tools

In today's fast-paced industrial operations, enhancing team collaboration through digital communication tools is vital for boosting efficiency. Effective communication not only streamlines workflows but also fosters a culture of collaboration among team members. By leveraging digital solutions, organizations can break down communication barriers, ensuring that information flows seamlessly across departments. This integration ultimately leads to improved coordination and quicker decision-making processes.

Digital tools play a crucial role in enhancing workplace communication by allowing teams to share insights, monitor project progress, and provide timely feedback. Whether through video conferencing platforms, chat applications, or project management software, these tools are designed to create an interactive environment where team members can engage and resolve issues in real time. As companies embrace these technologies, they can expect a significant increase in productivity levels, ultimately driving overall operational efficiency.

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

This chart illustrates the efficiency improvements seen by implementing digital communication tools in industrial operations across five key areas.

Leveraging IoT Solutions for Continuous Performance Monitoring

The rapidly growing demand for global digital oilfield solutions emphasizes the necessity for operational efficiency and technological advancement, particularly in oil and gas exploration, production, and asset management. The integration of IoT solutions is critical for continuous performance monitoring, as it enables real-time data collection and analytics that drive informed decision-making. By leveraging IIoT and AI technologies, companies can optimize their operations, achieving significant improvements in performance and productivity.

According to market forecasts, the asset performance management market is expected to increase from $34.94 billion in 2025 to $91.80 billion by 2034, reflecting a compound annual growth rate (CAGR) of 11.33%. This growth signifies the increasing reliance on IoT-enabled monitoring systems across various industries. Moreover, the geostationary satellite IoT market is projected to reach a value of $1.34 billion in 2023, with expectations of a robust CAGR exceeding 20% during the forecast period from 2024 to 2032. Such advancements illustrate the significant role that IoT technologies are set to play in enhancing operational efficiency and overall industry performance.

Related Posts

-

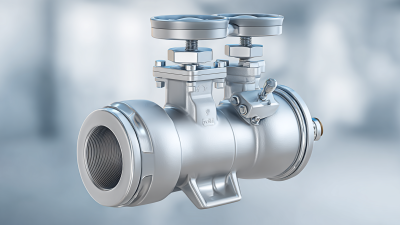

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

(780) 669-9420

(780) 669-9420