Blog

- Home

- Blog

How to Effectively Control Flow Through Valve Systems for Optimal Performance

In the realm of industrial operations, optimizing fluid movement is fundamental to maximizing efficiency and minimizing operational costs. The effectiveness of a system often hinges on the proper management of flow through valve systems. A recent report by the International Society of Automation highlights that approximately 30% of energy costs in process industries stem from improper valve control. This staggering statistic underscores the necessity for meticulous management of flow through valves to achieve optimal performance and resource conservation.

Industry expert Dr. Thomas R. Kimble, a recognized authority in fluid dynamics, emphasizes, "The control of flow through valve systems not only enhances system reliability but also significantly reduces energy consumption." His insights align with numerous studies indicating that improved valve positioning and response times can lead to substantial energy savings and increased system longevity. By embracing cutting-edge technologies and methodologies for valve control, industries can not only meet the growing demands for operational efficiency but also contribute to sustainability efforts by minimizing resource waste associated with fluid handling.

The pursuit of effective flow control through valve systems is, therefore, more than a technical necessity—it is a strategic imperative that can yield economic and environmental benefits. As organizations strive toward these goals, the implementation of advanced control strategies and intelligent systems becomes essential for not only enhancing operational performance but also not compromising on cost-effectiveness.

Understanding Valve Systems: Key Components and Functionality

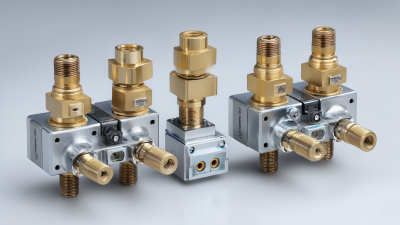

Valves are integral components in fluid control systems, playing a crucial role in regulating flow, pressure, and temperature across various industries. Understanding the key components and functionality of valve systems is essential for optimizing performance. Typically, a valve system comprises several key elements, including the valve body, actuator, and control mechanism. The valve body provides the structure for fluid flow, while the actuator, which may be manual or automated, serves to open or close the valve based on system requirements. Control mechanisms, often integrated with sensors and feedback loops, ensure precise operation tailored to specific pressure and flow demands.

According to a report by Global Market Insights, the valve market is projected to reach $100 billion by 2027, driven largely by the growing need for efficient resource management in industrial applications. Research indicates that proper valve selection and maintenance can lead to a 20-30% improvement in system efficiency. Moreover, advanced technologies such as smart valves, which use IoT capabilities for real-time monitoring, provide operators with critical data to make informed decisions. This integration not only enhances overall system reliability but also contributes to significant cost savings by reducing downtime and maintenance requirements. Understanding the nuances of these components can lead to more effective flow control and improved overall system performance.

Flow Control Through Valve Systems

Importance of Flow Control in Valve Systems for Performance

Effective flow control in valve systems is critical for optimizing the performance of processes across various industries. According to a report by Global Industry Analysts, the demand for precision flow control systems is projected to grow significantly, driven by the need for improved efficiency and reduced operational costs. In industrial applications, maintaining the correct flow rates through valves can lead to enhanced system reliability and longevity, thus avoiding costly downtimes and maintenance.

The importance of flow control becomes evident when examining its effects on energy consumption and overall productivity. The Hydraulic Institute reports that optimizing flow control can lead to energy savings of up to 30% in fluid systems. This is particularly vital in sectors such as water treatment and chemical processing, where even minor adjustments in flow rates can result in significant variations in operational efficiency. By integrating advanced flow control technologies and techniques, industries can achieve greater precision and responsiveness in their systems, aligning with sustainability goals and regulatory requirements. Such improvements not only enhance performance but also contribute to more eco-friendly operations, reducing the carbon footprint associated with excessive energy use.

How to Effectively Control Flow Through Valve Systems for Optimal Performance - Importance of Flow Control in Valve Systems for Performance

| Metric | Value | Unit | Impact on Performance |

|---|---|---|---|

| Max Flow Rate | 500 | L/min | Determines system capacity |

| Pressure Drop | 20 | kPa | Affects energy efficiency |

| Response Time | 0.5 | s | Influences control precision |

| Leakage Rate | 0.01 | L/h | Indicates maintenance needs |

| Temperature Range | -10 to 90 | °C | Ensures material compatibility |

Techniques for Adjusting and Controlling Flow in Valves

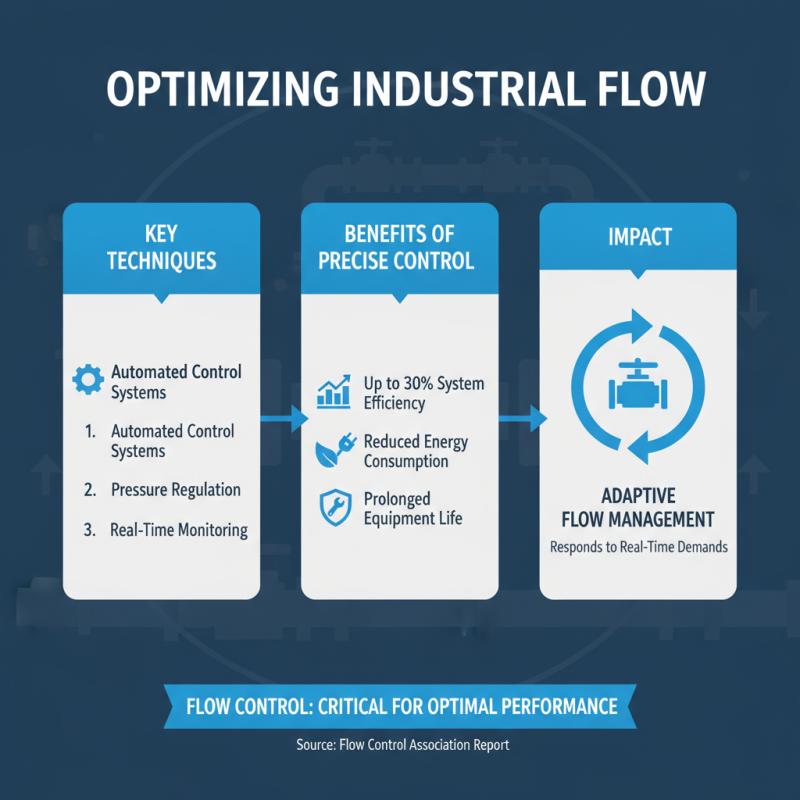

Controlling flow through valve systems is critical for optimizing performance across various industrial applications. Techniques for adjusting and controlling flow effectively encompass a range of strategies, including the use of automated control systems, pressure regulation, and real-time monitoring. According to a report by the Flow Control Association, proper valve flow control can improve system efficiency by up to 30%, reducing energy consumption and prolonging equipment life. This highlights the importance of implementing precise flow control measures that can adapt to real-time process demands.

One effective technique involves the integration of automatic control valves with smart sensors that monitor flow rates and adjust valve positions accordingly. This allows for dynamic adjustments to maintain desired flow conditions without manual intervention. Furthermore, utilizing variable frequency drives (VFDs) in conjunction with flow control valve systems can yield significant energy savings. Research from the American Society of Mechanical Engineers indicates that VFD applications can lead to a 25% reduction in pump energy usage when combined with flow control strategies. By prioritizing these advanced techniques, industries can ensure optimal performance and enhance operational efficiency.

Common Issues in Valve Systems and Their Solutions

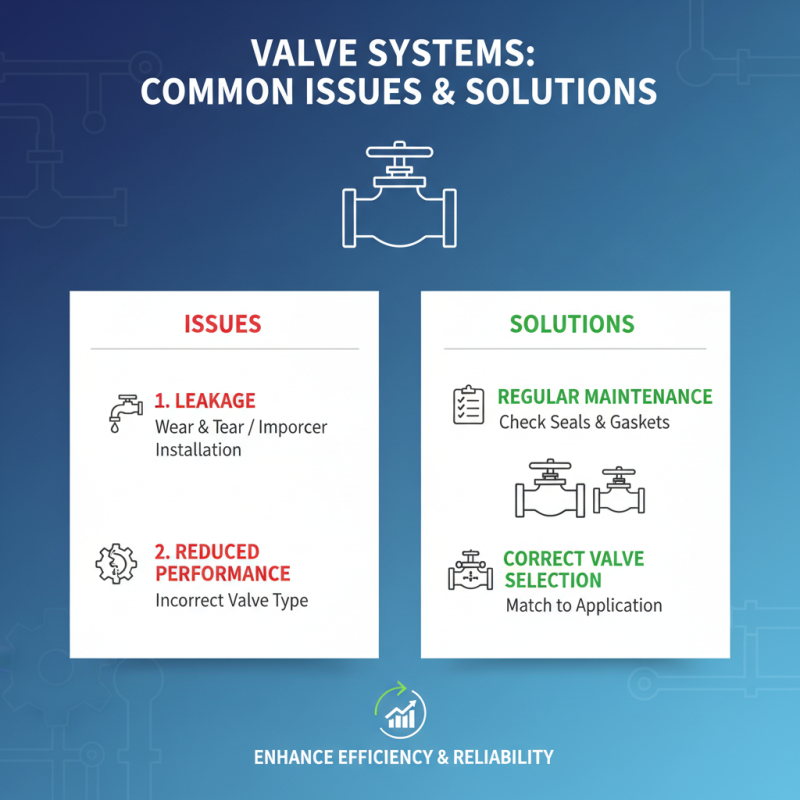

Valve systems are crucial components in various industries, yet they often encounter common issues that can hinder their performance. One prevalent problem is leakage, which can result from wear and tear or improper installation. To mitigate this, regular maintenance checks should be implemented, focusing on seals and gaskets, ensuring they are in good condition. Additionally, using the correct valve type for the specific application can significantly reduce the risk of leakage and enhance overall efficiency.

Another common issue is blockage, which can occur due to debris or corrosion buildup within the valve. This can lead to restricted flow and ultimately impact system performance. To address this, routine inspections and cleaning are essential. Employing strainers or filters upstream of the valve can also prevent debris from entering the system, thereby extending the life of the valve and maintaining optimal flow rates. Proactive measures, such as choosing appropriate materials and performing regular upkeep, are vital in overcoming these challenges and ensuring the longevity of valve systems.

Best Practices for Maintenance and Optimization of Valve Systems

Effective maintenance and optimization of valve systems are crucial for achieving optimal performance in industrial applications. According to a report by the International Society of Automation, up to 60% of all valve failures can be traced back to improper maintenance practices. Regular inspections and timely repairs can significantly enhance system reliability and reduce downtime, translating to substantial cost savings. It is crucial to develop a proactive maintenance schedule based on real-time monitoring of performance metrics, which allows for the early identification of potential issues before they escalate.

Tips: Implement a predictive maintenance strategy that utilizes advanced diagnostics and condition monitoring technologies. This approach can help operators anticipate valve wear and potential failures, enabling them to schedule maintenance during planned downtime rather than facing unexpected shutdowns. Additionally, training staff on best practices for valve operation and maintenance can lead to improved system performance and lifespan.

Regular optimization of valve settings is essential for maintaining efficient flow control. Data from the American Society of Mechanical Engineers suggests that improperly adjusted valves can cause energy losses of up to 30% in some systems. By continuously analyzing flow rates and pressure levels, organizations can fine-tune their valve systems to minimize losses and enhance overall system efficiency.

Tips: Consider employing advanced simulation tools that model valve performance under various operating conditions. This can provide valuable insights into how adjustments will impact system efficiency, helping operators to make informed decisions that maximize performance while minimizing energy consumption.

Related Posts

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Top Insights on Through Valve Technology for 2025 and Beyond

(780) 669-9420

(780) 669-9420