Blog

- Home

- Blog

How to Choose the Right Working Valve for Your Project?

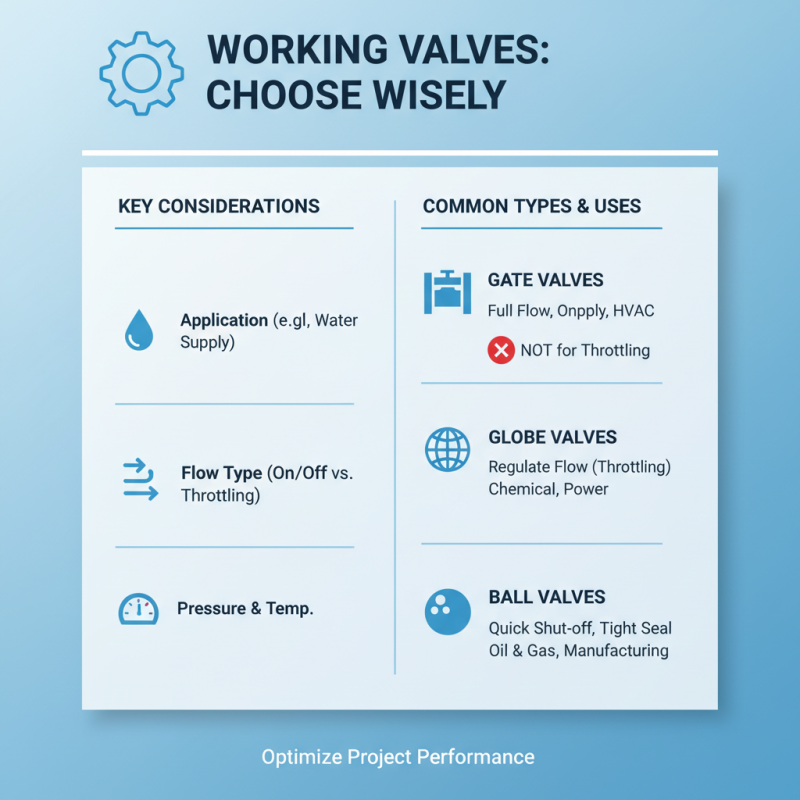

Choosing the right working valve for your project is crucial. A working valve controls fluid flow in various systems. Selecting the best one can save time and resources.

Consider the specifics of your project. Different applications require different valve types. A mismatch can lead to inefficiency or even failure. Take into account factors like pressure, temperature, and the medium involved.

Many overlook essential details during selection. Some valves may seem appropriate but fall short under certain conditions. Reflect on your project needs carefully to avoid costly mistakes. Choosing a working valve should align with both performance and reliability.

Factors to Consider When Selecting a Working Valve for Your Project

Choosing the right working valve is crucial for project success. Factors such as pressure rating, size, and valve type greatly influence performance. According to a report by the Valve Manufacturers Association, approximately 30% of valve failures result from incorrect sizing. This emphasizes the need to accurately measure flow requirements and ensure compatibility.

Material selection is another critical factor. Different materials respond to various chemicals and temperatures. A study revealed that about 15% of maintenance costs stem from material failure in valves. Understanding the operating environment is essential. Will the valve face corrosive substances? Is high heat a concern? These questions guide the material choice.

Lastly, keep an eye on operational efficiency. A right-sized valve can improve overall system efficiency by up to 25%. Designing systems without considering valve dynamics could lead to inefficiencies. Regularly reviewing valve selection processes is advisable. It helps identify gaps and areas for improvement. An ongoing evaluation can lead to better choices in future projects.

Types of Working Valves and Their Applications in Various Industries

Choosing the right working valve is essential for your project's success. Various types of working valves serve different purposes across multiple industries. For example, gate valves are commonly used in water supply systems. They provide full flow when fully open. However, they may not be the best choice for throttling applications due to their design limitations.

Ball valves offer a reliable solution for quick shut-off. They can handle high-pressure situations with ease. In contrast, globe valves are better suited for controlling flow due to their unique structure. They provide more precise flow regulation but come with a higher pressure drop. Many engineers overlook this when selecting valves, often opting for convenience over functionality.

In the chemical industry, diaphragm valves play a critical role. They prevent contamination by creating a barrier between the fluid and the actuator. However, they may not have the same flow capacity as other types. It's vital to thoroughly assess your project's needs before making a choice. Every valve type has its strengths and weaknesses, and one size definitely does not fit all.

Understanding Valve Specifications: Size, Pressure, and Material Considerations

Choosing the right working valve involves understanding key specifications. Size is critical. A valve that is too large will provide minimal control. Conversely, a small valve may restrict flow. Consider the pipe dimensions and the expected flow rate. Every project requires a precise fit to ensure efficiency.

Pressure ratings are equally important. Valves must withstand the maximum pressure of the system. Misjudging this can lead to failures. Materials also play a crucial role. Different environments demand different materials. Corrosion-resistant materials are vital in harsh conditions. Think about the fluids being handled. Each aspect contributes to the valve's suitability.

Sometimes, one specification overshadows the others. For instance, focusing solely on pressure may mean the size is overlooked. It’s essential to balance these factors. Make informed choices based on project needs. Test different combinations. Reflect on past experiences to avoid repeating mistakes. A thoughtful approach can save time and costs.

How to Choose the Right Working Valve for Your Project?

This chart illustrates the important specifications to consider when selecting a valve for your project. The dimensions include size, pressure rating, and material type, which are crucial for ensuring optimal performance and compatibility with your systems.

Evaluating the Operating Conditions for Optimal Valve Performance

Choosing the right working valve involves careful evaluation of operating conditions. Start by identifying the media flowing through the valve. Temperature and pressure play critical roles in valve selection. High temperatures may require specific materials, while pressure conditions dictate valve type.

Tips: Check the fluid's properties. Is it corrosive or abrasive? Understanding these details ensures better performance.

Next, consider the valve's location in the system. Will it be easily accessible for maintenance? Hard-to-reach valves can become troublesome over time. Maintenance needs must be factored in early.

Tips: Schedule regular checks on the installed valves. Ignoring this can lead to failures. Look for wear signs like leaks or abnormal noises.

Lastly, understand the flow characteristics. Will the valve fully open or regulate flow? Often, users overlook this. Matching the valve’s capabilities with system demands is crucial. Careful planning here saves resources and time.

Cost vs. Quality: Making a Sustainable Choice for Your Valve Selection

When selecting a working valve for your project, the balance between cost and quality is crucial. A cheaper option may seem like a good deal at first. However, it could lead to higher maintenance costs later on. Sometimes, a low initial investment results in frequent replacements. Over time, this can significantly increase your overall expenses.

Quality valves often come at a higher price, but they may save you money in the long run. Choosing durable materials can minimize the risk of leaks and breakdowns. A sturdy valve can maintain its performance under various conditions. Consider the specific needs of your project. This reflection can help you identify the right balance between cost and quality.

Think about the environment too. A sustainable choice in valve selection contributes positively. Valves designed for efficiency can reduce waste and energy costs. In the end, investing in quality often pays off, both financially and environmentally. Evaluate your options carefully and prioritize long-term benefits over short-term savings.

Related Posts

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

-

How to Fix a Working Valve Issues Troubleshooting Guide

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Top Benefits of Engineered Valves for Industrial Applications

(780) 669-9420

(780) 669-9420