Blog

- Home

- Blog

Top 10 Tips for Choosing the Right Valve Steel for Your Projects

When embarking on a project that requires durability and precision, selecting the right valve steel is critical. According to industry expert Dr. Emily Carter, a prominent metallurgist with over two decades of experience in the field, "The choice of valve steel can make or break the efficiency and longevity of your project." This emphasizes the importance of making informed decisions based on the specific demands of your application.

Valve steel encompasses a variety of alloys designed for resilience and performance in challenging environments. With myriad options available, understanding the properties of different steel grades is essential for engineers and manufacturers. Factors such as corrosion resistance, tensile strength, and heat treatment processes are crucial for ensuring that the chosen valve steel meets the operational requirements and standards of safety.

As we delve into the top ten tips for selecting the right valve steel for your projects, it is imperative to consider both the technical specifications and the broader implications of your choices. By prioritizing quality and understanding the nuances of valve steel selection, you can enhance the overall performance and reliability of your systems, leading to successful project outcomes.

Understanding Valve Steel Types and Their Applications

When selecting valve steel for your projects, it's crucial to understand the various types and their specific applications. Valve steels are generally classified into several categories, including carbon steels, alloy steels, and tool steels, each with distinct characteristics. For instance, high-carbon steels are commonly used for their hardness properties, making them suitable for high-temperature environments. Meanwhile, alloy steels, which may include elements like chromium and molybdenum, provide enhanced strength and resistance to wear, making them ideal for demanding industrial applications.

One essential tip is to consider the operating conditions your valves will face. Understanding the temperature and pressure ranges will help you choose a steel that can withstand these challenges. Additionally, evaluating corrosion resistance is vital, especially for applications involving aggressive fluids. Another practical piece of advice is to consult with material experts to ensure that the selected steel meets industry standards and can provide longevity and reliability in your specific use case.

Finally, always keep in mind that the manufacturing process can also influence the performance of valve steel. Techniques such as heat treatment can enhance the durability and strength of the steel, so it’s beneficial to inquire about these processes when making your selection. Adopting a meticulous approach to choosing the right valve steel will ultimately lead to better project outcomes and increased efficiency in operations.

Top 10 Valve Steel Types and Their Applications

Key Properties to Consider When Selecting Valve Steel

When selecting valve steel for your projects, understanding the key properties of different steel types is crucial. The primary factors to consider include strength, corrosion resistance, and temperature tolerance. Strength is vital, as the steel must withstand high pressure and stress conditions without yielding. Corrosion resistance is essential for maintaining the integrity of valves in various environments, ensuring longevity and reliability. Additionally, evaluating the temperature tolerance of the steel will help ensure it can perform effectively under the specific conditions of your application.

One key tip when choosing valve steel is to assess the specific needs of your project. For instance, if your application involves exposure to harsh chemicals or extreme temperatures, look for steel qualities that exhibit high resistance to these conditions. Another important consideration is the manufacturing process of the valve steel, as this can affect its overall performance and durability. Opt for materials that are produced with advanced techniques to ensure superior quality and reliability.

Lastly, collaborating with professionals who have extensive experience in valve applications can provide invaluable insights. They can guide you in making informed decisions based on the latest advancements in materials and their practical applications. By focusing on these essential properties and seeking expert advice, you can confidently choose the right valve steel that meets the demands of your project.

Top 10 Tips for Choosing the Right Valve Steel for Your Projects - Key Properties to Consider When Selecting Valve Steel

| Property | Importance | Recommended Steel Grades |

|---|---|---|

| Corrosion Resistance | Essential for longevity in harsh environments | Stainless Steel (e.g., 304, 316) |

| Temperature Resistance | Critical for high-temperature applications | Alloy Steel (e.g., 4130, 441) |

| Strength | Needed to withstand high pressures | Carbon Steel (e.g., A106, A105) |

| Ductility | Allows for flexibility and forming | Low Alloy Steel (e.g., 8620) |

| Weldability | Important for assembly and repair | Mild Steel (e.g., S235) |

| Impact Toughness | Necessary for safety in dynamic environments | Structural Steel (e.g., S355) |

| Fatigue Resistance | Important for cyclic loading applications | High Strength Low Alloy Steel (e.g., 1045) |

| Machinability | Affects production efficiency | Free Machining Steel (e.g., AISI 12L14) |

| Availability | Influences lead time and cost | Common Alloys (e.g., A36) |

| Cost Effectiveness | Balances budget and performance | Economical Choices (e.g., 1018) |

Common Material Standards for Valve Steel Used in Projects

When selecting the appropriate valve steel for your projects, it is essential to understand the common material standards that govern these materials. Valve steels are typically categorized by their properties, which affect their performance and longevity in various applications. Common standards include ASTM A182, which specifies forged or rolled alloy and stainless steel pipe flanges, fittings, and valves, and ASTM A351, outlining the requirements for castings. These standards ensure that the materials meet specific mechanical and chemical properties, essential for their intended service conditions.

Another critical standard is SAE J416, which details the chemical composition requirements for various grades of valve steels. It emphasizes the importance of alloying elements such as chromium and molybdenum, which enhance hardenability and resistance to high-temperature oxidation. Understanding these material standards will help project managers and engineers make informed decisions when selecting valve steel, ensuring that the final products will withstand the operational pressures and temperatures associated with their intended use. Proper adherence to these standards not only optimizes performance but also extends the lifespan of valve components in demanding environments.

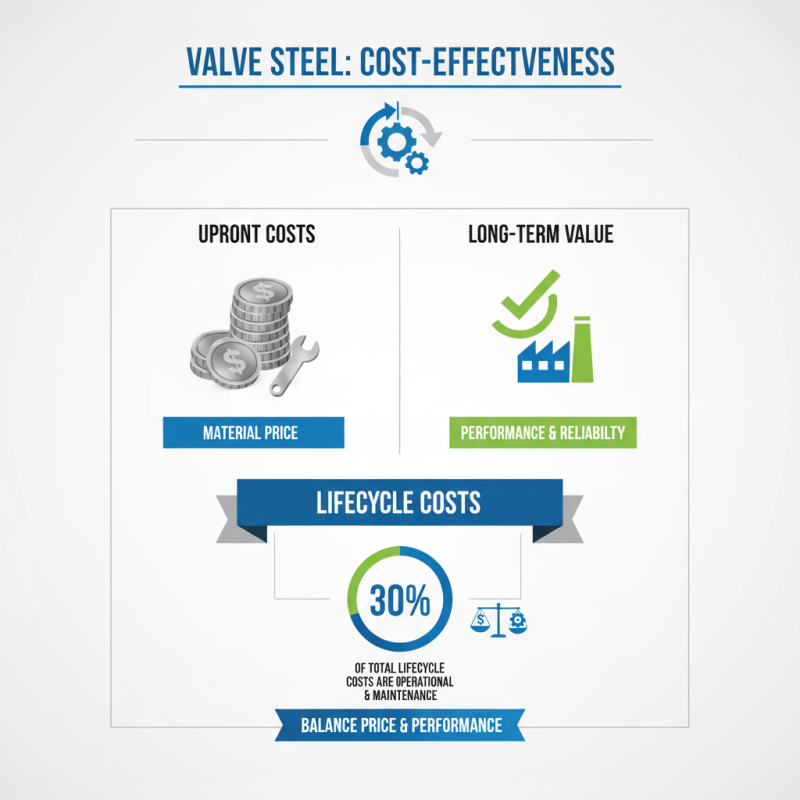

Evaluating Cost-Effectiveness of Different Valve Steel Options

When evaluating the cost-effectiveness of different valve steel options, it is crucial to balance upfront material costs with long-term performance and reliability. According to a report by the International Valve Manufacturers Association, the choice of valve materials can impact operational efficiency and maintenance expenses, potentially accounting for as much as 30% of total lifecycle costs. This statistic highlights the importance of not just considering floor price but also the performance capabilities of various steel grades under operational pressures and environments.

High-strength steels, despite their higher initial costs, may lead to significant savings over time due to their enhanced durability and resistance to corrosion and wear. For instance, a comparative study revealed that using higher-grade materials could extend the lifespan of valves by nearly 50%, reducing the frequency of replacements and repairs. Additionally, data from the American Society of Mechanical Engineers suggests that investing in premium valve steel can result in up to a 20% decrease in total maintenance costs over a decade, making them a financially sound choice for projects requiring high reliability. Understanding these cost dynamics is essential for project managers aiming to optimize their budget while ensuring effective and safe operations.

Best Practices for Sourcing Quality Valve Steel Products

When sourcing quality valve steel products, it is critical to prioritize materials that meet industry standards and specifications. According to a report by the American Society for Testing and Materials (ASTM), valve steels should typically adhere to stringent requirements regarding tensile strength, corrosion resistance, and temperature stability. The correct grade of steel not only ensures durability and performance but also compliance with regulatory standards essential in critical applications, such as oil and gas or power generation.

Additionally, consider the source of your valve steel. Research indicates that purchasing from manufacturers that are ISO certified provides significant assurance of product quality and consistency. An analysis by the International Organization for Standardization (ISO) highlighted that companies adhering to these standards experience up to a 30% reduction in product defects. It is also advisable to request detailed material certification to verify the mechanical properties and chemical composition of the steel. This diligence in the sourcing process contributes significantly to the success and longevity of your projects, ensuring that your valves can withstand the operational demands they will face.

Related Posts

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

What is Steel Valves and How They Benefit Your Industrial Applications

-

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

(780) 669-9420

(780) 669-9420