Blog

- Home

- Blog

How to Choose the Right Valve Applications for Your Industry Needs?

Choosing the right valve applications for your industry can be challenging. Every industry has unique needs. Understanding these needs is crucial for optimal performance.

Industries such as oil, gas, and water management require specific valve types. Each application has distinct requirements. For example, a pressure-sensitive environment may need robust, high-performance valves. On the other hand, a standard drainage system could use simpler solutions.

It's important to evaluate the environment where valves will be used. Factors like temperature, pressure, and fluid type matter greatly. Incorrect choices can lead to inefficiency and safety hazards. Reflect on your current valve applications, and ask if they truly meet your operational demands. Choosing wisely can enhance productivity and reduce costs.

Understanding Different Types of Valves and Their Functions

Valves play a critical role across various industries. They control the flow of liquids and gases in diverse systems. Understanding different valve types is essential for making the right choice. Gate, globe, ball, and butterfly valves serve distinct purposes based on the operational needs.

Gate valves excel in on/off control. They create minimal resistance when fully open, ideal for pipeline applications. Globe valves, on the other hand, provide precise flow regulation. Their design allows for throttling, but they can increase pressure loss. If you need to manage flow accurately, globe valves might be your best bet.

Butterfly valves are lightweight and compact, perfect for large-scale applications. Their rotating disc allows for quick opening and closing. However, they may not handle high-pressure situations well. Understanding these nuances can prevent costly mistakes. Each valve type has its strengths and weaknesses. Doing thorough research helps ensure you choose the right valve for your industry needs.

Identifying Industry-Specific Requirements for Valve Applications

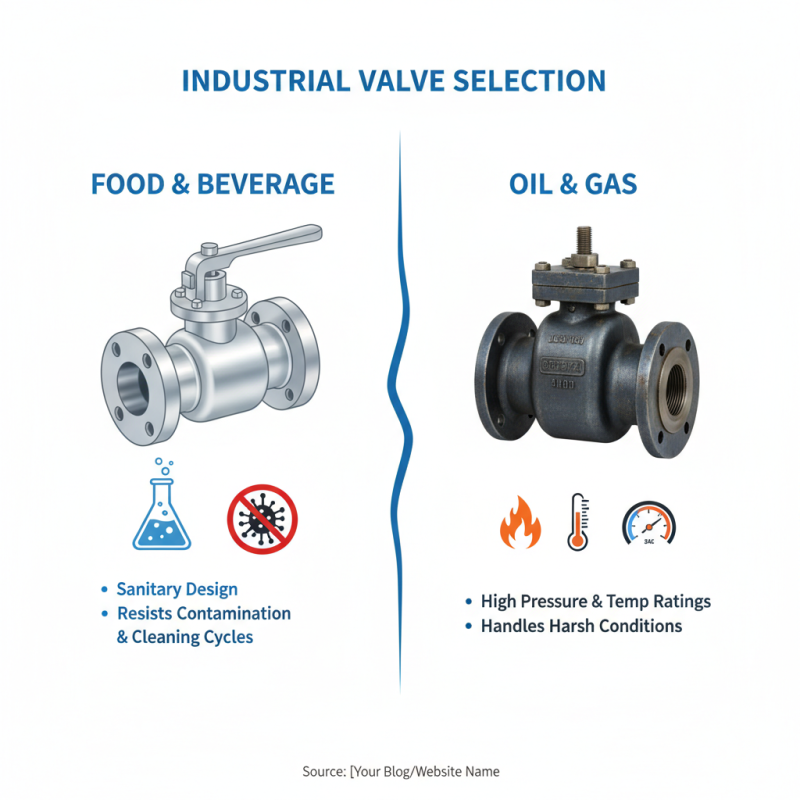

When selecting valves for specific industries, understanding the unique requirements is crucial. Different sectors have distinct needs based on their processes. For example, the food and beverage industry often requires sanitary valves that prevent contamination. These valves must withstand cleaning cycles without degrading. In contrast, the oil and gas industry demands valves with high pressure and temperature ratings to handle harsher conditions.

Consider the environment where the valve will operate. In chemical processing, valves must resist corrosive substances. Choosing the wrong material can lead to failures and safety hazards. Some industries, like pharmaceuticals, also have strict regulations. Valves here must not only perform reliably but also meet stringent compliance standards.

Identifying the specific functions valves need to fulfill can be complex. Some applications may require automatic control, while others need manual operation. It's essential to assess how these factors influence efficiency and safety. Often, professionals overlook these details, leading to costly mistakes. Engaging with industry experts can help clarify these needs. Understanding industry-specific requirements ultimately leads to better decisions in valve applications.

Evaluating Performance Metrics for Valve Selection

Choosing the right valve for your application requires careful evaluation of performance metrics. Consider parameters such as flow rate, pressure drop, and size. Each valve type has unique characteristics. Not all valves fit every situation. Evaluate your specific needs before making a choice.

**Tip:** Always calculate your system's flow requirements. It helps narrow down options effectively. Make sure to consider the medium being controlled. Different fluids react differently, which affects performance.

You may find that some metrics are not straightforward. For example, the relationship between pressure and flow can be complex. Some valves may perform well under certain conditions but fail in others. Testing in real conditions is crucial. Don't just rely on theoretical data.

**Tip:** Ask for real-world performance reports. This can provide insights into valve reliability. Feedback from end-users can reveal hidden issues. Be open to revisiting your choices if new information arises. This approach enhances your decision-making process significantly.

Valve Applications Performance Metrics

Considering Material Compatibility and Environmental Factors

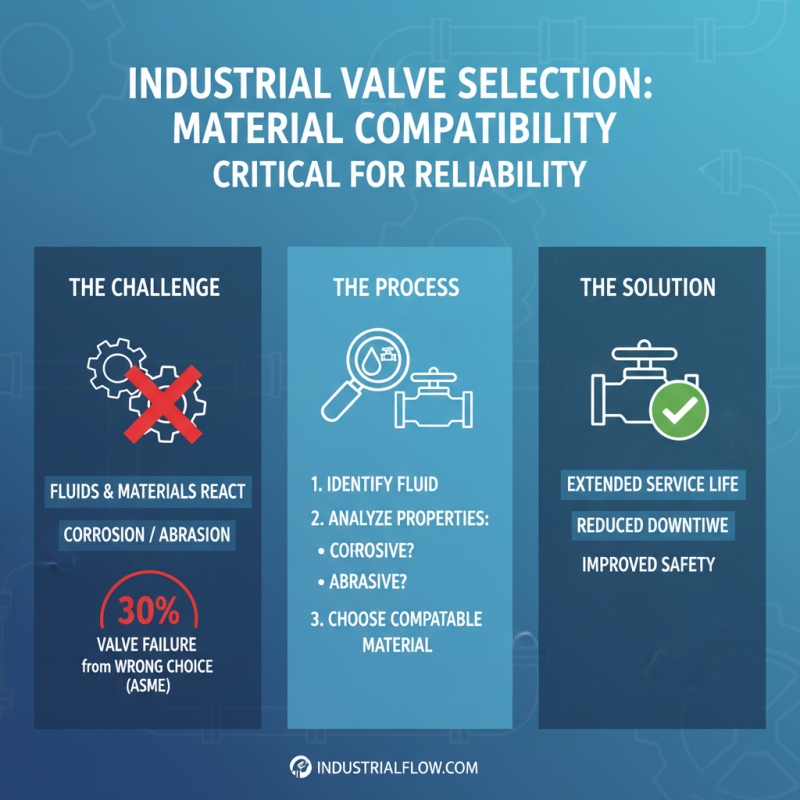

When selecting valves for industrial applications, material compatibility is critical. Each material interacts differently with various substances. According to a report from the American Society of Mechanical Engineers, improper material selection can lead to valve failure in 30% of industrial applications. Understanding the process fluid and its corrosive or abrasive properties is necessary.

Environmental factors also influence valve performance. For example, extreme temperatures can cause certain materials to degrade. A study from the Institute of Industrial Engineers highlights that 25% of failures occur due to thermal expansion mismatches. If the environment includes factors like humidity, it’s even more crucial to consider material selection. Using inappropriate materials can lead to leakage, increasing the risk of accidents and downtime.

The challenge lies in balancing performance and longevity. While some materials promise better performance, they may not withstand environmental stressors. Research indicates that around 40% of industries don't review compatibility regularly. This oversight could result in costly repairs and operational inefficiencies. Such statistics urge industries to reflect on their valve selections.

Assessing Maintenance and Lifecycle Costs of Valves

Maintaining valves in industrial settings can lead to significant cost implications. Many organizations underestimate these costs in their budgets. According to a recent industry report, maintenance contributes up to 40% of total lifecycle costs for valves. This means that choosing the right valve for your specific application is critical.

Tip: Assess the specific maintenance needs of each valve type. Some valves require more frequent maintenance than others. Frequent short downtime might be acceptable in non-critical applications. However, it is crucial to consider how long the valve can be offline in critical processes.

Lifecycle costs also vary widely, depending on the valve design and materials used. For example, a valve that is less expensive upfront might incur higher operational costs later. It is essential to look at the total cost of ownership. An analysis by a leading industry consultancy indicates that investing in durable materials can be advantageous in the long run.

Tip: Evaluate real-world performance data. Test results from similar applications can provide insights into the actual costs and benefits. Relying solely on manufacturer claims might lead to oversights. Dive into your production needs and ensure the valve choice aligns well with your operational requirements.

Related Posts

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

Top Insights on Through Valve Technology for 2025 and Beyond

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

(780) 669-9420

(780) 669-9420