Blog

- Home

- Blog

How to Choose the Right Guide Valves for Your System?

Selecting the correct guide valves for your system is crucial for operational efficiency. A report by the American Society of Mechanical Engineers highlights that improper valve choices can lead to a 30% decrease in system performance. Guide valves, integral to fluid control, must align with specific requirements. Industry expert Dr. Samuel Reed states, "Choosing the right guide valves can make or break your system's efficiency." His insight emphasizes the importance of carefully evaluating your options.

When considering guide valves, factors such as material compatibility and pressure ratings are vital. Not all guide valves are created equal, and mismatches can cause significant issues. The Valve Manufacturers Association reports that nearly 20% of system failures are traced back to inadequate valve selection. This reflects the need for thorough analysis and expert consultation in the selection process.

The complexity of fluid systems means that a one-size-fits-all approach is inadequate. Each application demands unique considerations. It's essential to reflect on your system's specific needs to avoid costly mistakes. In the evolving landscape of fluid control, careful selection and expert advice are more essential than ever.

Understanding the Purpose of Guide Valves in Your System

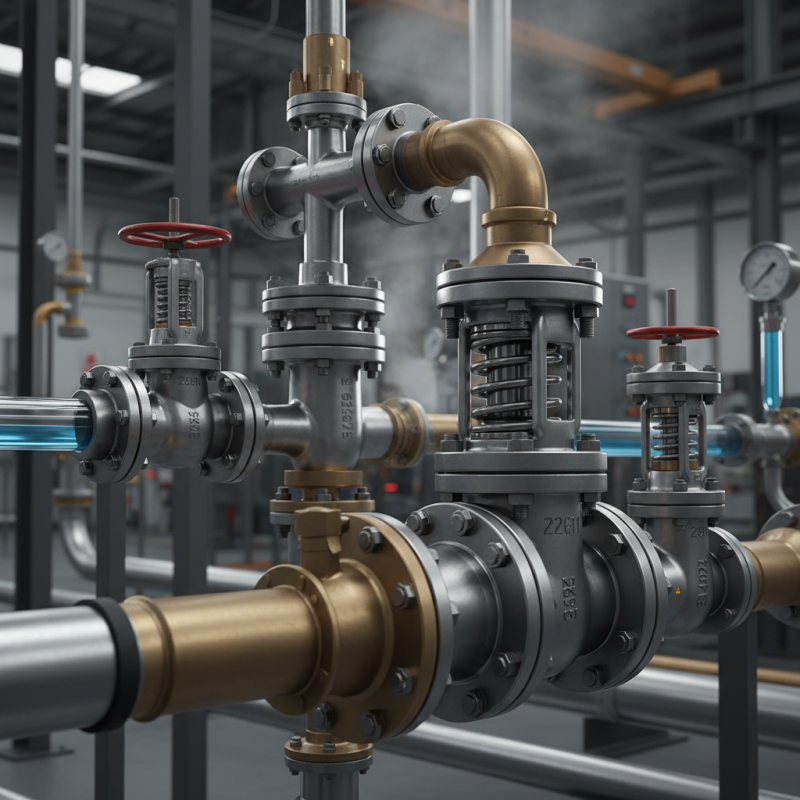

Guide valves play a crucial role in various systems, controlling flow and ensuring efficiency. Understanding their purpose is essential for optimal performance. These valves regulate the direction and pressure of fluids in a system. They can prevent backflow and help in controlling the speed of flow, which is vital in many applications.

Choosing the right guide valves involves assessing system needs carefully. Consider the type of fluid, pressure, and temperature. Some systems may not perform effectively with standard options. This mismatch can lead to significant operational issues. Reflecting on past experiences might reveal where choices went wrong.

Think about how guide valves interact with other components. Each system is unique, and generalizations may not apply. Pay attention to the materials used in manufacturing the valves. They must withstand specific conditions to avoid premature failure. An oversight in this area can lead to leaks or catastrophic breakdowns, making it a notable point for consideration.

Identifying Key Factors for Selecting Guide Valves

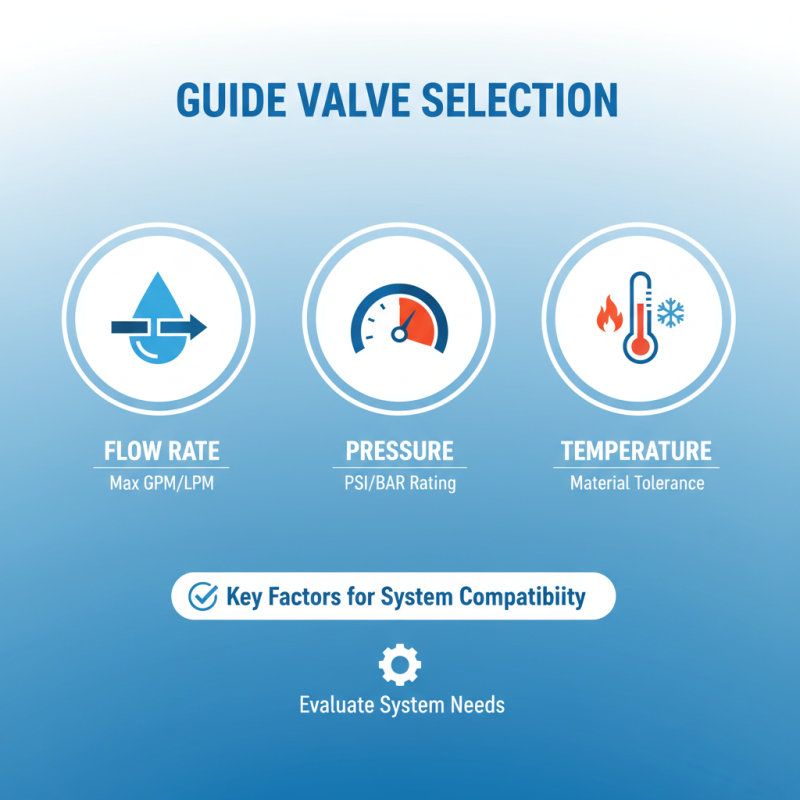

When selecting guide valves, several key factors must be evaluated carefully. Start by understanding the flow requirements of your system. What is the maximum flow rate? Ensure the valves can handle it. Consider the pressure levels too. High pressure often dictates a stronger valve design. Also, temperature variations can affect performance. Choose materials that withstand the highest expected temperatures.

Next, think about the application type. Will the valves be used in a clean water system or something more aggressive? Different fluids require different materials and designs. Don’t overlook the size of the valves; they must fit your piping system precisely. Measure pipe diameters accurately to avoid mismatched fittings. Lastly, factor in maintenance needs. Valves that are easier to service might save time and costs in the long run. Reflect on these choices carefully, as a poor selection can lead to leaks or system failures.

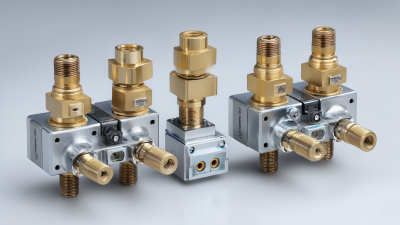

Comparing Different Types of Guide Valves and Their Applications

Choosing the right guide valves is crucial for your system's efficiency. Guide valves come in various types, each suited for specific applications. For example, ball valves are excellent for quick shut-off, while globe valves provide more precise flow control. Think about what you need. Make a list of your system's demands and your working environment.

Tips: Consider the material of the valve. Different environments require different materials. For example, corrosive environments call for special coatings.

You might face challenges in selecting the right type. Sometimes the technical specifications can be overwhelming. It's essential to consult guidelines and industry standards. Understand that not every valve fits every system.

Tips: Always measure your connections accurately. Small discrepancies can lead to leaks or inefficient performance.

Ultimately, investing time in understanding these valves pays off. Evaluate how each type aligns with your operational needs. Make decisions with a clearly defined purpose for better outcomes.

Comparison of Different Types of Guide Valves and Their Applications

Evaluating Performance Specifications for Optimal System Compatibility

When selecting guide valves for your system, performance specifications are crucial. Evaluate the flow rate, pressure rating, and temperature limits of each valve. These factors influence how well a valve can work within your system's parameters. Consider your application requirements closely. A mismatch can lead to inefficiency or even system failure.

Tips: Always check compatibility. Not all valves are universal. Pay attention to the materials used. Corrosion can be a silent killer, affecting valve longevity.

Also, think about the mode of operation. Manual valves require frequent checks, while automated options offer convenience. However, automation adds complexity. Limitations will arise. Regular maintenance is needed for all types.

In essence, a thoughtful selection process will safeguard your system’s operability. Remember, the right choice isn't just about the best specs, but how they align with your unique needs.

Maintaining and Troubleshooting Guide Valves for Longevity

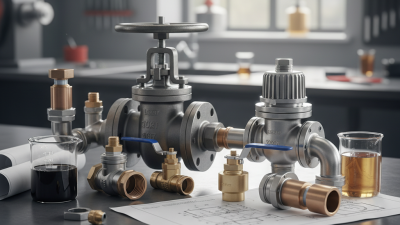

When it comes to guide valves, maintenance and troubleshooting are key to ensuring their longevity. Regular inspections can help catch issues before they escalate. Look for signs of wear or corrosion. This will save time and money down the road.

Tips: Always clean the valves regularly. Dirt buildup can hinder performance. Use appropriate cleaning agents to avoid damage. Monitor operational pressure closely. Abnormal pressure readings often indicate a problem within the system.

If issues arise, troubleshooting becomes essential. Start by checking the actuator and connections. Listen for unusual noises. These could signal a malfunctioning component. Document any changes in the valve's operation. This information is valuable for future reference.

Tips: Don’t ignore small leaks. They can lead to bigger problems. Replace worn seals promptly to maintain efficiency. Consider creating a maintenance schedule. Consistency is crucial for optimal performance.

How to Choose the Right Guide Valves for Your System? - Maintaining and Troubleshooting Guide Valves for Longevity

| Valve Type | Material | Operating Pressure | Temperature Range | Application | Maintenance Frequency |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | Up to 600 psi | -20°C to 120°C | Water, Oil | Yearly |

| Gate Valve | Carbon Steel | Up to 1500 psi | -29°C to 425°C | Oil & Gas | Quarterly |

| Globe Valve | Brass | Up to 300 psi | -10°C to 100°C | Water, Gas | Semi-Annual |

| Butterfly Valve | Plastic | Up to 200 psi | -15°C to 80°C | Water Treatment | Annually |

Related Posts

-

Top Benefits of Engineered Valves for Industrial Applications

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

How to Choose the Right Working Valve for Your Project?

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Top Insights on Through Valve Technology for 2025 and Beyond

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

(780) 669-9420

(780) 669-9420