Blog

- Home

- Blog

How to Choose the Right Guide Valves for Your Project?

Choosing the right guide valves for your project can be challenging. Experts emphasize the importance of matching application needs with valve specifications. Richard Anderson, a renowned valve specialist, once stated, “The right guide valve can make or break a system's efficiency.” Understanding your project's requirements ensures better decision-making.

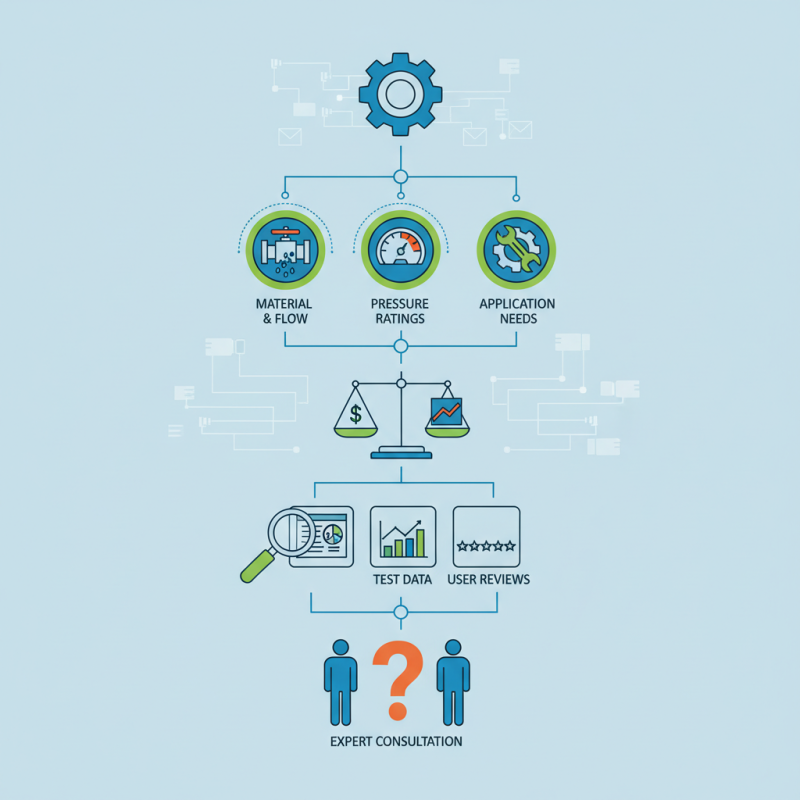

When selecting guide valves, consider factors such as material, pressure ratings, and flow characteristics. Every project has unique challenges, and a one-size-fits-all approach rarely succeeds. For example, materials should withstand specific environmental conditions. It is crucial to engage with suppliers to gather insights and options.

Reflect on past decisions too. Have you prioritized cost over quality? Often, cheaper valves lead to operational issues. It's essential to balance budget constraints with performance requirements. Take time to analyze product specifications, test data, and user reviews. In this complex landscape, informed choices stem from diligent research and expert consultations.

Understanding the Basics of Guide Valves in Industrial Applications

Guide valves play a crucial role in managing fluid flow within many industrial systems. They control pressure and direct the movement of fluids in pipes. Understanding their essentials can enhance project efficiency. It's vital to know how guide valves function and where they fit into your application.

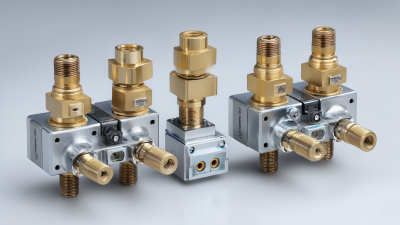

These valves can come in various designs, including globe and gate types. Each design has specific advantages and limitations. For example, globe valves are great for throttling but may restrict flow. Gate valves, while effective for on-off control, may not provide the same level of precision. It's essential to align the valve type with your project's demands.

You might encounter challenges when selecting the right guide valve. Some projects may face space constraints, while others require specific material compatibility. Evaluating these factors can help in making the right choice. However, issues like maintenance accessibility and wear resistance may not always be apparent at first glance. Reflecting on these aspects can lead to better decision-making in the long run.

How to Choose the Right Guide Valves for Your Project?

| Valve Type | Application | Material | Size (Inches) | Pressure Rating (PSI) | Temperature Range (°F) |

|---|---|---|---|---|---|

| Globe Valve | Flow regulation | Stainless Steel | 2 | 150 | -20 to 300 |

| Ball Valve | On/Off control | Brass | 1.5 | 200 | -40 to 250 |

| Butterfly Valve | Throttling | PVC | 4 | 100 | -10 to 140 |

| Check Valve | Prevent backflow | Cast Iron | 3 | 250 | 0 to 350 |

| Solenoid Valve | Automatic control | Aluminum | 1 | 150 | -10 to 180 |

Key Factors Impacting the Selection of Guide Valves

Selecting the right guide valves is crucial for any engineering project. Understanding key factors can significantly impact your decision. One major consideration is the fluid type being handled. Different fluids, such as corrosive chemicals or high-temperature gases, require specific materials. A recent industry report indicated that nearly 30% of valve failures stem from material incompatibility.

Pressure ratings also play a vital role. Valves must withstand the pressures of the system to function effectively. A study found that inadequate pressure ratings contributed to over 20% of operational downtime in various industries. It is essential to match the valve rating to the system requirements, ensuring reliability and safety.

Additionally, maintenance requirements can affect your choice. Some valves require more upkeep than others. This can lead to increased operational costs. According to research, about 15% of maintenance budgets are spent on valve related issues. So, evaluating maintenance needs can save resources in the long run. Aim for a balance between performance, durability, and ease of maintenance. Making informed decisions will help avoid future problems.

Comparative Analysis of Material Choices for Guide Valves

When selecting guide valves for a project, material choice plays a crucial role. Several factors influence this decision. Common materials include stainless steel, brass, and plastic. Each offers unique advantages and disadvantages.

Stainless steel is known for its durability and resistance to corrosion. It's suitable for harsh environments. However, it can be costly and heavy.

Brass is another popular option. It provides good corrosion resistance and is easier to machine. However, brass may not perform well in extreme temperatures.

Plastics are lighter and more affordable. They resist corrosion effectively but might not withstand high pressures. Each material has its strengths and weaknesses. Understanding these can make a difference in your project.

Mistakes can happen when choosing materials. Sometimes, engineers prioritize cost over performance, leading to failures. Others might select a material based purely on availability. This can result in delays or issues later. Reflecting on these choices can help in future projects. A thorough analysis is always beneficial.

Balancing cost, performance, and suitability should guide your decision process.

Evaluating Performance Metrics for Efficient Guide Valve Operation

Choosing the right guide valves can be critical for any project. One essential aspect to consider is performance metrics. Efficiency is often measured in terms of flow rate, pressure drop, and response time. Recent industry reports indicate that valves with faster response times can improve overall system performance. For instance, a reduction in response time by just 10 milliseconds can increase efficiency by 15%.

When selecting guide valves, pay attention to the materials. They affect not just durability but also response and pressure capabilities. Studies show that stainless steel valves perform better under high pressure compared to other materials. This can result in fewer operational issues and lower maintenance costs.

**Tips:** Always assess the application requirements. Matching the valve type with the specific needs is crucial. For applications involving fluid dynamics, a valve with low flow resistance is beneficial. This not only enhances efficiency but also prolongs the valve’s lifespan. Regularly review the performance metrics throughout your project lifespan. Sometimes, failure to monitor these can lead to discrepancies and unexpected outcomes, causing delays.

Guide Valves Performance Metrics

This chart provides an overview of key performance metrics for guide valves in various operational aspects: flow rate, pressure drop, leakage rate, and response time. Understanding these metrics can help in selecting the right guide valve for your project.

Maintenance Considerations for Long-Term Reliability of Guide Valves

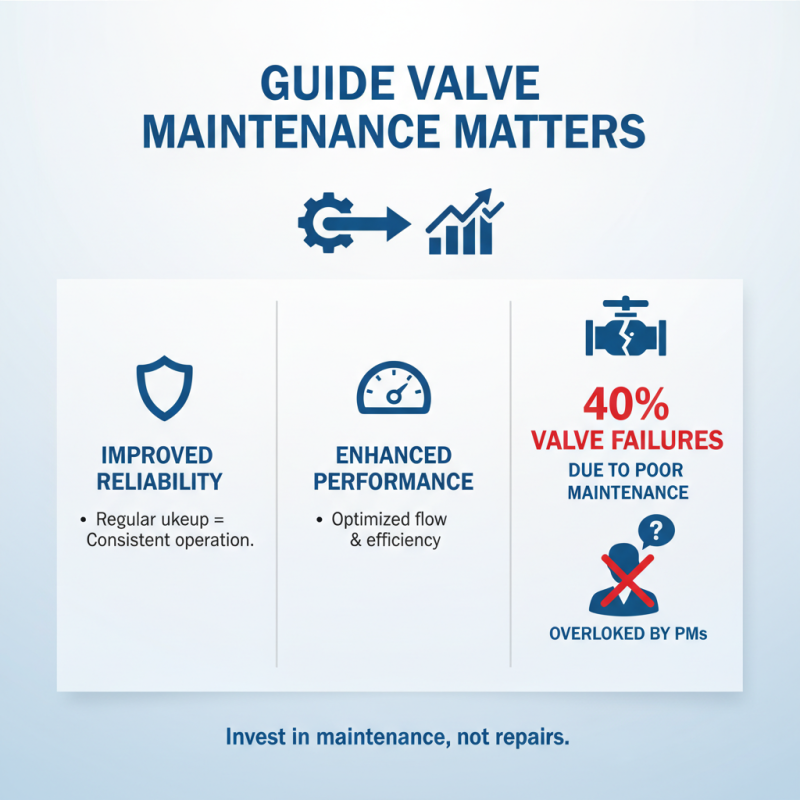

When selecting guide valves for your project, consider their long-term maintenance. Regular upkeep improves their reliability and performance. According to industry data, nearly 40% of valve failures result from inadequate maintenance practices. This is often overlooked by project managers.

Tip: Schedule regular inspections. Look for wear and tear that can signal issues. Valve seals and seats are common failure points. Monitoring these can prevent major problems later.

Utilizing predictive maintenance strategies is essential. Data shows that implementing such strategies can reduce failure rates by up to 70%. This proactive approach can extend the lifespan of guide valves significantly.

Tip: Train your team on maintenance best practices. A knowledgeable team can spot potential issues before they escalate. Simple steps can lead to effective long-term functioning of guide valves.

Related Posts

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

10 Best Valve Applications for Efficient Industrial Processes

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

(780) 669-9420

(780) 669-9420