Blog

- Home

- Blog

Why Choose a 4 Gate Valve for Your Industrial Applications?

In industrial settings, choosing the right valve is crucial. The 4 gate valve stands out for its unique efficiency. With its design, it manages fluid flow with precision. This type of valve offers reliable performance in various applications.

The 4 gate valve includes features that enhance its functionality. For instance, the parallel seating allows for better sealing. In addition, it minimizes the risk of leaks. However, it’s essential to consider the specific needs of your system.

Some might overlook the importance of this valve type. Not all environments will benefit equally from a 4 gate valve. Evaluating your application is key. After all, even the best components require careful selection.

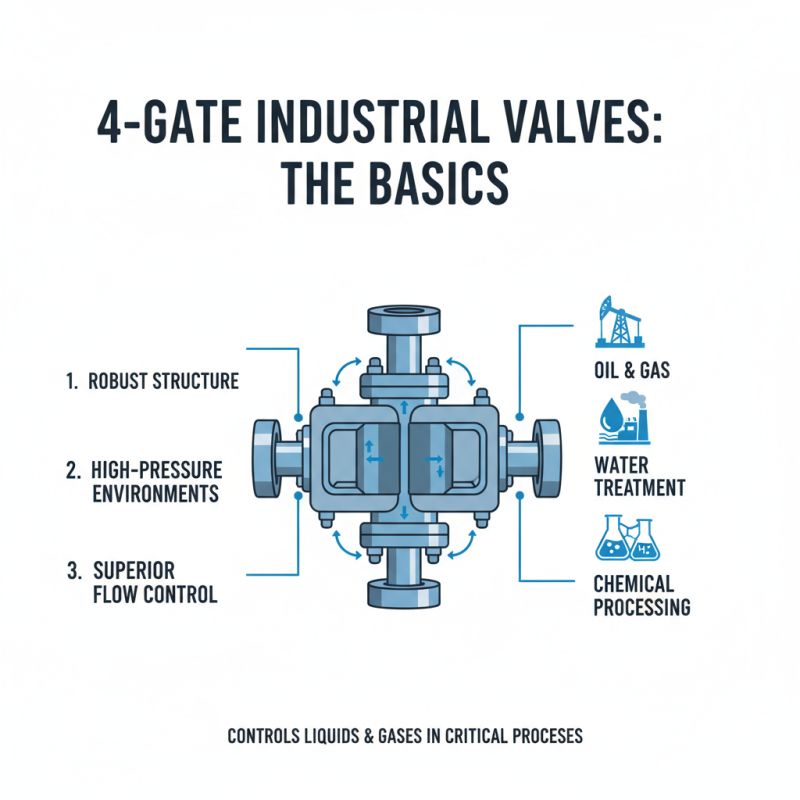

Understanding the Basics of 4 Gate Valves in Industry

When discussing 4 gate valves in industrial applications, understanding their basics is essential. These valves control the flow of liquids and gases in a variety of processes. A 4 gate valve typically offers a robust structure, which makes it suitable for high-pressure environments. Its design allows for better flow control compared to traditional valves. This is crucial in industries such as oil and gas, water treatment, and chemical processing.

Tips to consider when choosing a 4 gate valve: Ensure you assess the specific pressure and temperature requirements of your application. The material of construction is also key. It should withstand the media being processed. A mismatch can lead to failures. Another point to reflect upon is maintenance. Regular inspection is vital, yet often overlooked.

Also, think about the overall layout of your piping system. A poorly positioned valve can cause inefficiencies. Ensure access for maintenance. Sometimes, users underestimate the significance of valve placement. A well-placed valve can save time and enhance safety.

Key Advantages of 4 Gate Valves Over Other Valve Types

In industrial applications, choosing the right valve is crucial. A

4 gate valve stands out due to its unique features.

It provides a reliable sealing ability,

reducing leakage significantly. This is vital in high-pressure systems

where safety is a concern. The 4 gate design allows for better flow control

compared to other valve types. It manages large volumes of fluid effectively and minimizes turbulence.

Another advantage is durability. These valves are often constructed from

robust materials, ensuring a longer lifespan. They can withstand extreme temperatures

and pressures, which is essential in many industrial settings. Maintenance is straightforward, though it still requires attention.

Regular checks are necessary to ensure optimal performance. Sometimes, operators

overlook this, which can lead to unforeseen issues.

Moreover, 4 gate valves have a compact design. This can save space in tight installations.

However, one must consider their weight. They can be heavier than other types, which might not suit every application.

Choosing the right valve requires a careful assessment of your specific needs.

Consider all aspects, not just the advantages.

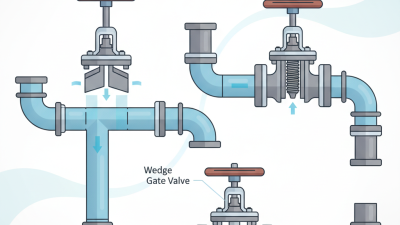

Applications of 4 Gate Valves in Various Industrial Sectors

In various industrial sectors, the 4 gate valve plays a crucial role. These valves are designed for flow control in piping systems. Their unique design allows for better sealing and reduced risk of leaks. This feature is essential in oil and gas, where safety is a top priority. However, some users may overlook maintenance, leading to performance issues.

In the water treatment industry, 4 gate valves manage flow efficiently. They can handle varying pressures and temperatures. Proper installation is critical; a poor fit can lead to significant problems. It’s important to assess compatibility with existing systems.

Manufacturing processes also benefit from these valves. They are used in steam systems and chemical processing. The ability to quickly isolate sections of piping is invaluable. Yet, operators must remain vigilant. Neglecting regular inspections can result in failures that disrupt operations.

Factors to Consider When Selecting a 4 Gate Valve

When selecting a 4 gate valve for your industrial applications, several factors come into play. Each application is unique. Understanding your specific needs is crucial.

Consider the valve size. Choose one that matches your pipeline dimensions. A proper fit prevents leaks and ensures efficient operation. Pay attention to the pressure rating as well. If it’s too low, failures may occur under high-pressure conditions. Likewise, materials matter. They must withstand your application’s environment, whether it's high temperatures or corrosive substances.

**Tips:** Always check compatibility with your media. Some materials cannot handle specific fluids or gases. Don't overlook maintenance needs. A valve that is hard to service may lead to costly downtime.

Performance in the field is essential too. Sometimes, specifications look great on paper but fail in practice. Real-world testing can reveal flaws. Assess how the valve performs under stress. Practical feedback from users is invaluable. These insights can guide your decision.

Why Choose a 4 Gate Valve for Your Industrial Applications?

| Factor | Description | Advantages | Applications |

|---|---|---|---|

| Durability | Designed to withstand high pressure and temperature. | Long lasting and reduced maintenance costs. | Oil and gas, chemical processing. |

| Flow Control | Provides precise control over fluid flow. | Improved process efficiency. | Water treatment, HVAC systems. |

| Safety | Designed with safety leak-proof features. | Minimizes the risk of leaks and spills. | Pharmaceuticals, food processing. |

| Versatility | Can be used in various configurations and settings. | Adaptable for different types of systems. | Industrial manufacturing, energy sectors. |

Maintenance and Operational Best Practices for 4 Gate Valves

When operating 4 gate valves, maintenance is key to ensuring longevity and efficiency. Regular inspections are essential. Check for leaks and corrosion regularly. Small issues can escalate into large problems if ignored. Lubricating moving parts enhances performance. Use appropriate greases that withstand the working environment.

Operational best practices also matter significantly. Staff training is crucial for proper valve handling. Misoperation can lead to instant failures. Understanding valve mechanics can minimize risks. Ensure valves are compatible with the system's pressure and temperature requirements. Operating outside these limits could cause failure.

Consideration of environmental factors is vital too. Dust and debris can affect valve performance. Invest in protective covers to shield valves from contaminants. Also, maintain a clean working area. This helps in identifying potential issues early. While 4 gate valves are robust, neglect can lead to inefficiencies. Make it a habit to routinely assess valve conditions.

Why Choose a 4 Gate Valve for Your Industrial Applications?

This chart illustrates the operational efficiency and maintenance frequency of 4 Gate Valves compared to other valve types in industrial applications.

Related Posts

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

-

What is Steel Valves and How They Benefit Your Industrial Applications

(780) 669-9420

(780) 669-9420