Blog

- Home

- Blog

Why Choose a DHV Gate Valve for Your Piping Needs?

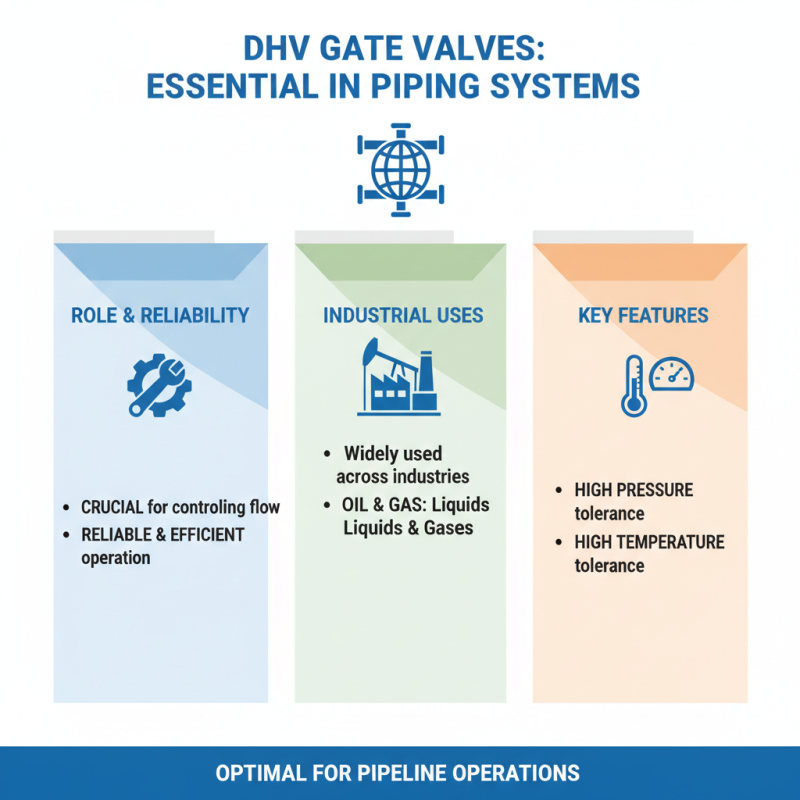

When it comes to piping systems, choosing the right components is crucial. A widely recommended option is the DHV gate valve. Known for their durability and reliability, DHV gate valves can handle diverse applications. These valves control flow effectively, allowing for smooth operations in various settings.

Many industries prefer DHV gate valves for their robust construction. They are often made from high-quality materials, ensuring longevity. This is particularly important in environments with high pressure and temperatures. Users appreciate their straightforward design, making installation and maintenance easier. However, some may overlook their specific needs, leading to suboptimal choices.

In conclusion, selecting a DHV gate valve should align with operational requirements. Investing in quality equipment ensures system efficiency. Reflecting on the type of valve needed for your project can make a significant difference.

Understanding DHV Gate Valves and Their Functionality

Gate valves play a vital role in regulating the flow of liquids and gases in piping systems. They are designed to allow or block flow with minimal resistance. The structure is quite simple, generally featuring a wedge that moves up and down within the valve body. This design ensures that the flow can easily move through when fully opened, minimizing pressure loss.

One important aspect to consider is their operational efficiency. Gate valves can take a moment to open or close fully. In emergencies, this delay might be problematic. While they excel at providing full flow, they should not be used for throttling purposes. Their primary function is on or off, not partial flow regulation. Additionally, they require proper maintenance to prevent leaks and ensure longevity.

It’s crucial to select the correct size and material for your application. A mismatch can lead to poor performance. Another point to ponder is the environment in which they will be used. Different materials can resist certain chemicals or high temperatures better than others. The decision-making process can feel overwhelming. Each choice carries implications for durability and efficiency. Recognizing this can guide you toward a more informed decision.

Key Advantages of Using DHV Gate Valves in Piping Systems

When selecting a valve for piping systems, DHV gate valves present notable advantages. These valves excel in providing a straight-line flow path. This design minimizes turbulence and pressure loss. According to industry reports, their flow efficiency can exceed 90%. This makes them ideal for large-diameter piping systems.

Durability is another key benefit of DHV gate valves. They are designed to withstand high pressure and extreme temperatures. Many can operate in environments exceeding 500 degrees Fahrenheit. This longevity leads to reduced maintenance costs. Operators can expect a longer lifespan, reducing the need for replacements.

**Tips:** Regular inspections help identify wear and tear. Use non-destructive testing methods to assess valve integrity. Consider a valve's material compatibility with your system to avoid unforeseen issues. Always ensure proper installation to maximize performance.

Why Choose a DHV Gate Valve for Your Piping Needs?

| Feature | Description | Advantages |

|---|---|---|

| Durability | Constructed from robust materials to withstand high pressures and temperatures. | Long lifespan, reducing replacement frequency and maintenance costs. |

| Flow Capacity | Offers a straight-through flow design with minimal resistance. | Improves system efficiency and decreases energy consumption. |

| Sealing Performance | Utilizes advanced sealing technology for leak-proof operation. | Enhances system safety and prevents contamination. |

| Versatility | Suitable for various applications including water, oil, and gas. | Adaptable to diverse requirements across industries. |

| Ease of Operation | Designed for quick and easy manual or automated operation. | Increases accessibility and reduces downtime during operation. |

Applications of DHV Gate Valves in Various Industries

When it comes to piping systems, DHV gate valves play a crucial role. These valves are widely used in various industries due to their reliability and efficiency. In the oil and gas sector, gate valves help control the flow of liquids and gases. They can handle high pressure and temperature, making them essential for pipeline operations.

In water treatment plants, DHV gate valves are vital for regulating the water supply. They ensure proper flow rates, allowing for efficient processing. These valves can also be found in HVAC systems. They help control heating and cooling, ensuring optimal performance and energy efficiency.

Tips: Always choose the right valve size. An oversized valve can lead to flow problems. Regular maintenance is critical for longevity. Inspect valves periodically to ensure they function correctly. It’s better to replace a faulty valve than to deal with leaks later.

In the chemical industry, gate valves are used to manage corrosive substances. Their robust design minimizes the risk of failure. However, incorrect installation can lead to serious issues. Proper training for installation teams is essential to avoid costly mistakes.

Comparison of DHV Gate Valves with Other Valve Types

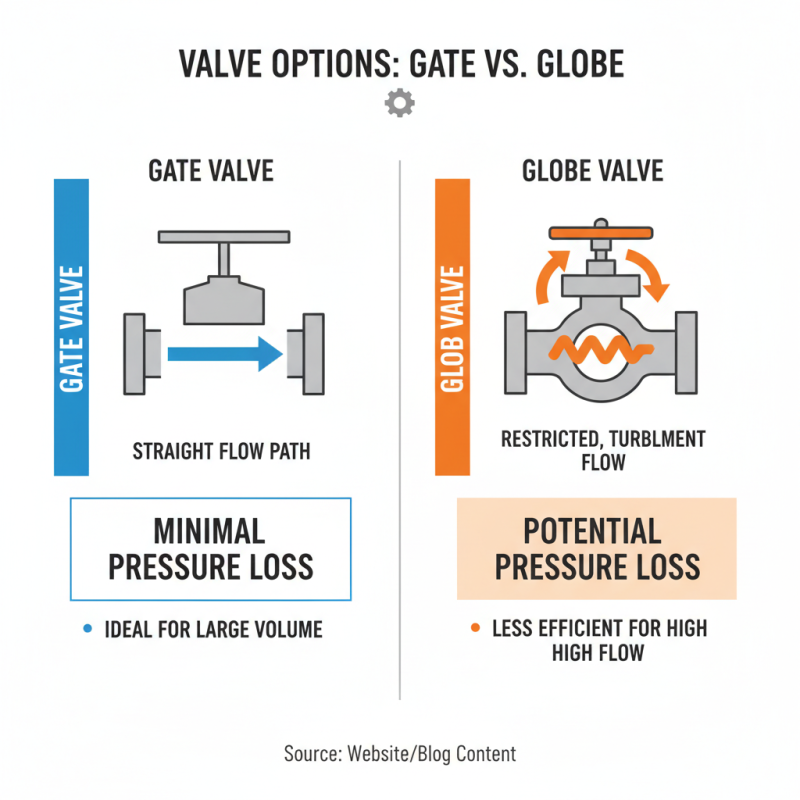

When considering valve options, gate valves often stand out. They are known for providing a straight flow path. This design minimizes pressure loss, making them suitable for large volume applications. In contrast, globe valves can restrict flow. Their design creates turbulence, potentially leading to inefficiencies.

Another key difference lies in operation. Gate valves are ideal for on/off control. Once fully open, they do not impede flow. However, this can be a drawback. Gate valves do not regulate flow well. If precision is required, a globe or ball valve may be more effective.

Material choice is also crucial. Gate valves can be made from various materials. This flexibility allows for better adaptability. On the other hand, some materials may not hold up in certain environments. It's essential to consider the application. In some cases, a robust valve may fail quietly. Regular maintenance is necessary to ensure optimal performance.

Maintenance Tips for Optimal Performance of DHV Gate Valves

When it comes to gate valves, proper maintenance is crucial. Regular upkeep ensures optimal performance and extends the life span of the valve. According to industry reports, poorly maintained gate valves can lead to leaks and inefficiencies, costing companies significantly. In fact, maintenance neglect can lead to an increase in operational costs by up to 30%.

To maintain your DHV gate valve, check for leaks regularly. A simple visual inspection can catch early signs of wear. If you notice any unusual vibrations or sounds, it may indicate a problem. Remember, small issues can escalate. Cleaning the valve and inspecting its components should be done at least once every six months.

Another important tip is to maintain proper lubrication of moving parts. Lack of lubrication can lead to corrosion or sticking issues. Industry standards recommend using suitable lubricants designed specifically for gate valves. Be sure to refer to manufacturer guidelines for the best practices for your specific valve type. Consistent maintenance should prevent many operational issues, yet neglect is often inevitable in busy environments. Stay vigilant.

Related Posts

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications?

(780) 669-9420

(780) 669-9420