Blog

- Home

- Blog

Why Choose DHV Gate Valve for Your Industrial Applications

In the realm of industrial applications, the selection of the appropriate valve type can significantly influence operation efficiency, safety, and cost-effectiveness. According to a recent report by the International Association of Industrial Valves, more than 30% of operational failures in major industries can be attributed to improper valve selection. This statistic underscores the critical importance of choosing the right products like the "dhv gate valve," which is renowned for its reliability and robust performance in high-pressure environments.

Experts in the field, such as Dr. Thomas Reynolds, a leading authority in valve technology, emphasize the advantages of using the "dhv gate valve." Dr. Reynolds notes, "The dhv gate valve is engineered for durability and precision, making it an optimal choice for industries that require uncompromised control over fluid flow." This perspective is corroborated by various case studies demonstrating that facilities utilizing the dhv gate valve system have reported up to a 25% increase in operational efficiency while significantly reducing maintenance costs.

In summary, the "dhv gate valve" embodies an essential solution for industries seeking to enhance fluid management systems. Its prevalence in critical applications is not merely coincidental; it is a testament to its superior design and the importance of informed decision-making in valve selection processes.

Key Features of DHV Gate Valves for Industrial Use

When selecting a gate valve for industrial applications, durability and performance are crucial.

The DHV gate valve stands out due to its robust construction, designed to withstand high pressure and temperature fluctuations typical in industrial environments.

According to a recent industry report by the American Society of Mechanical Engineers (ASME),

gate valves account for approximately 60% of the valve market in sectors like oil and gas, chemical processing, and water treatment,

attributing their popularity to their reliability and ease of operation.

Key features that enhance the performance of DHV gate valves include exceptional sealing capabilities and minimal pressure drop.

These valves are engineered with precision, ensuring that the flow path remains unobstructed when fully open, thus promoting efficiency.

The design often includes high-quality materials that resist corrosion and wear, leading to extended service life and lower maintenance costs.

In a survey conducted by the Valve Manufacturers Association (VMA),

it was reported that using quality gate valves can reduce operational downtime by over 30%,

indicating their role in enhancing overall productivity within industrial settings.

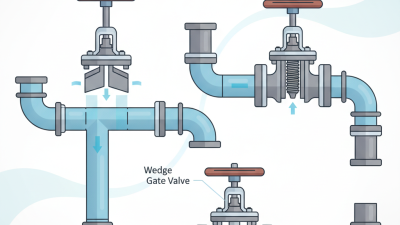

Furthermore, the installation of DHV gate valves is facilitated by their compatibility with various piping systems, allowing for versatile applications.

The valves meet stringent industry standards and certifications, providing an assurance of safety and reliability that is vital for operations where integrity and performance are non-negotiable.

In fact, according to National Institute of Standards and Technology (NIST) data,

the proper selection of industrial valves can lead to energy savings of up to 25%,

highlighting the importance of choosing the right equipment for industrial efficiency and sustainability.

Advantages of DHV Gate Valves in Fluid Control Systems

When selecting gate valves for fluid control systems, the advantages of using a high-quality option can greatly enhance operational efficiency and reliability. One key benefit of gate valves is their ability to provide a straight-flow path, which minimizes pressure drops and allows for unrestricted fluid passage. This characteristic is particularly valuable in industrial applications where maintaining flow rates is crucial. Additionally, gate valves can be fully opened or closed, making them ideal for applications requiring a quick shut-off mechanism without causing turbulence in the system.

Furthermore, the construction of gate valves often allows for better durability and longevity compared to other valve types. These valves are designed to withstand high pressures and temperatures, making them suitable for harsh industrial environments. The robust materials used in their manufacturing ensure that they can resist corrosion and abrasive substances, thereby reducing the need for frequent replacements. This durability translates to lower maintenance costs and enhanced system uptime, ultimately contributing to more efficient operations within fluid control systems.

Applications of DHV Gate Valves in Various Industries

DHV gate valves are widely utilized across various industries due to their robust design and reliability. In the oil and gas sector, these valves play a crucial role in controlling the flow of crude oil and natural gas. Their ability to provide a tight seal when fully closed makes them ideal for applications where leakage prevention is paramount. This characteristic is particularly important in upstream production and downstream refining processes, where system integrity is vital to operational safety and efficiency.

In water treatment facilities, DHV gate valves are essential for managing the flow of water and ensuring proper regulation within the treatment processes. Their simple yet effective design allows for easy maintenance, which is a critical factor in environments that require constant monitoring and adjustment of water flow. Furthermore, in the power generation industry, these valves are employed in steam and water pipelines to facilitate the control of high-pressure systems, promoting efficient energy production and distribution. Overall, the versatile applications of DHV gate valves underscore their importance in maintaining operational reliability across diverse industrial contexts.

Applications of DHV Gate Valves in Various Industries

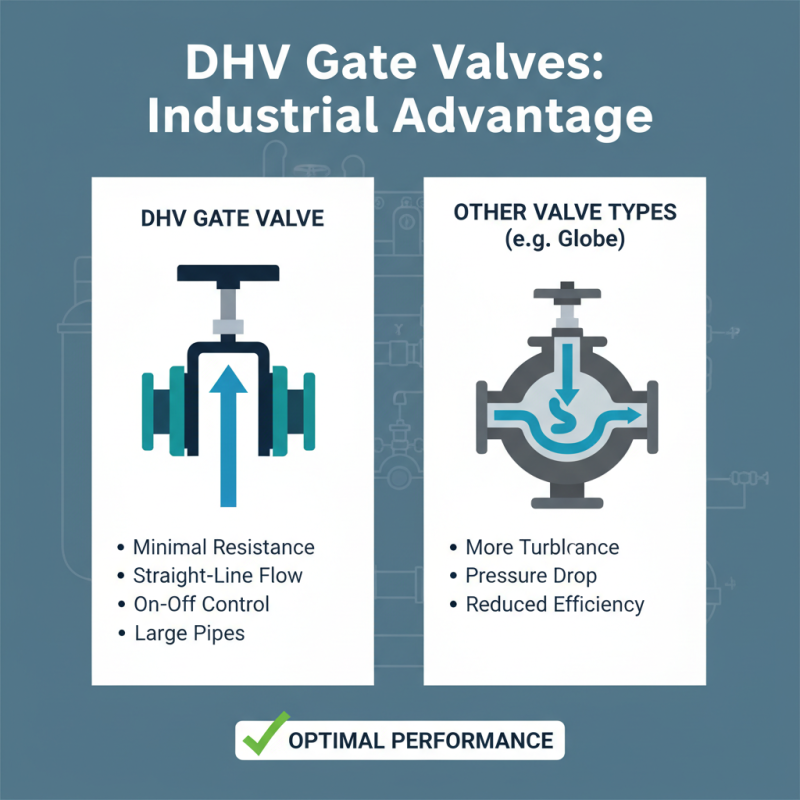

Comparative Analysis: DHV Gate Valves vs. Other Valve Types

When comparing DHV gate valves with other valve types, it’s essential to consider their unique advantages in industrial applications. Gate valves are primarily designed to provide a straight-line flow of fluid with minimal resistance, making them ideal for on/off control in larger pipes. In contrast, globe valves, although versatile, introduce more turbulence and pressure drop due to their design. For applications requiring minimal flow obstruction and maximum efficiency, the DHV gate valve stands out, ensuring optimal performance without the drawbacks associated with other valve types.

Another aspect to explore is the durability and maintenance considerations of DHV gate valves versus alternatives like ball or butterfly valves. Gate valves are typically more robust, handling extreme pressure and temperature conditions better than some other types. While ball valves offer quick operation, they may not be suitable for high-pressure systems over long durations, as they can wear out faster under extreme conditions. The DHV gate valve, with its simple construction, often requires less maintenance, translating to reduced downtime and maintenance costs in industrial settings.

Maintenance and Reliability of DHV Gate Valves in Operations

When it comes to industrial applications, the maintenance and reliability of gate valves are paramount. DHV gate valves have gained recognition for their robust design and extended operational lifespan. According to a recent industry report by the Valve Manufacturers Association, gate valves account for over 25% of all valve sales in the industrial sector, underscoring their importance in various applications, including water treatment, oil and gas, and chemical processing. The low-friction operation of DHV gate valves minimizes wear and tear, which correlates with reduced maintenance frequency and costs—key factors for industries aiming to optimize operational efficiency.

Additionally, the reliability of DHV gate valves is supported by longevity data that indicates a failure rate of less than 1% per year in optimal conditions. This level of reliability minimizes the risks associated with unscheduled downtimes and overhauls, allowing plants to run smoothly and efficiently. Industry experts advocate regular inspection schedules and maintenance training as best practices, as they can enhance the operational reliability of these valves even further. Data from the American Society of Mechanical Engineers highlights that proper maintenance protocols can increase the service life of valves by up to 40%, a significant advantage for companies that rely on consistent performance in their processes.

Why Choose DHV Gate Valve for Your Industrial Applications - Maintenance and Reliability of DHV Gate Valves in Operations

| Feature | Description | Benefits | Maintenance Frequency (Months) |

|---|---|---|---|

| Durability | Constructed from high-strength materials to withstand harsh conditions | Longer service life and reduced replacement frequency | 12 |

| Sealing Performance | Designed for tight sealing and minimal leakage | Enhanced efficiency and reduced operational costs | 18 |

| Ease of Maintenance | Simple design allows for quick inspections and repairs | Minimized downtime and labor costs | 6 |

| Adaptability | Versatile for various industrial applications and fluid types | Greater flexibility in operation and application scope | 24 |

| Cost-Effectiveness | Competitive pricing with long-term savings on maintenance | Improved ROI and reduced total cost of ownership | 12 |

Related Posts

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Top Benefits of Engineered Valves for Industrial Applications

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

2025 Top 10 Valve Control Innovations for Efficient Fluid Management

(780) 669-9420

(780) 669-9420