Blog

- Home

- Blog

Top 10 Best Valve Selection Tips for Optimal Performance?

In the realm of industrial processes, valve selection is crucial. Renowned valve expert Dr. Emily Carter once said, "Choosing the right valve can make or break system efficiency." Her insight highlights the importance of understanding valve types and compatibility.

Effective valve selection involves understanding flow dynamics. Different applications require unique valve designs. A ball valve may suit one setup while a butterfly valve fits another. It's vital to consider factors like pressure, temperature, and medium type.

Common pitfalls arise in valve selection. Oversizing or undersizing a valve could lead to performance issues. Also, neglecting maintenance can cause unexpected failures. Awareness of these challenges is essential for optimal results. Thoughtful valve selection can enhance productivity and reduce costs.

Understanding Valve Types and Their Applications

Valves are essential components in many systems. They control the flow of liquids and gases. Understanding valve types is key to selecting the right one for your application. There are many types of valves, including ball, gate, and butterfly valves. Each type serves a unique purpose. Ball valves are great for quick shut-off, while gate valves are better for on/off control. Butterfly valves offer a compact design, ideal for tight spaces.

Consider the application when choosing a valve. Think about the pressure, temperature, and the medium being controlled. Some valves might perform well under certain conditions but fail under others. For example, using a gate valve in a system with frequent cycling can lead to wear and tear. This could decrease performance. It's crucial to match the valve type with its intended use. If you're not careful, you may find yourself with a valve that doesn't fit your needs.

Installation matters too. A poorly installed valve can lead to leaks and inefficiencies. Proper alignment and torque are essential for optimal performance. Regular maintenance checks can help spot issues early. Remember, the right valve choice is about more than just function. It's about reliability, efficiency, and ensuring that your system runs smoothly. Mistakes in selection can be costly in the long run.

Top 10 Best Valve Selection Tips for Optimal Performance

| Tip No. | Selection Criteria | Valve Type | Applications |

|---|---|---|---|

| 1 | Understand Fluid Characteristics | Ball Valve | Water, Oil, Gas |

| 2 | Consider Pressure Ratings | Gate Valve | Pipeline Systems |

| 3 | Evaluate Temperature Conditions | Globe Valve | Steam Systems, HVAC |

| 4 | Assess Flow Requirements | Butterfly Valve | Water Distribution, Fire Protection |

| 5 | Check Material Compatibility | Check Valve | Prevent Backflow in Pipelines |

| 6 | Identify Installation Space | Pinch Valve | Slurries, Granular Solids |

| 7 | Consider Actuation Type | Solenoid Valve | Automated Systems |

| 8 | Review Maintenance Needs | Pressure Relief Valve | Safety Applications |

| 9 | Assess Lifecycle Costs | Float Valve | Water Tanks, Reservoirs |

| 10 | Consult with Experts | Diverter Valve | Multi-Stream Applications |

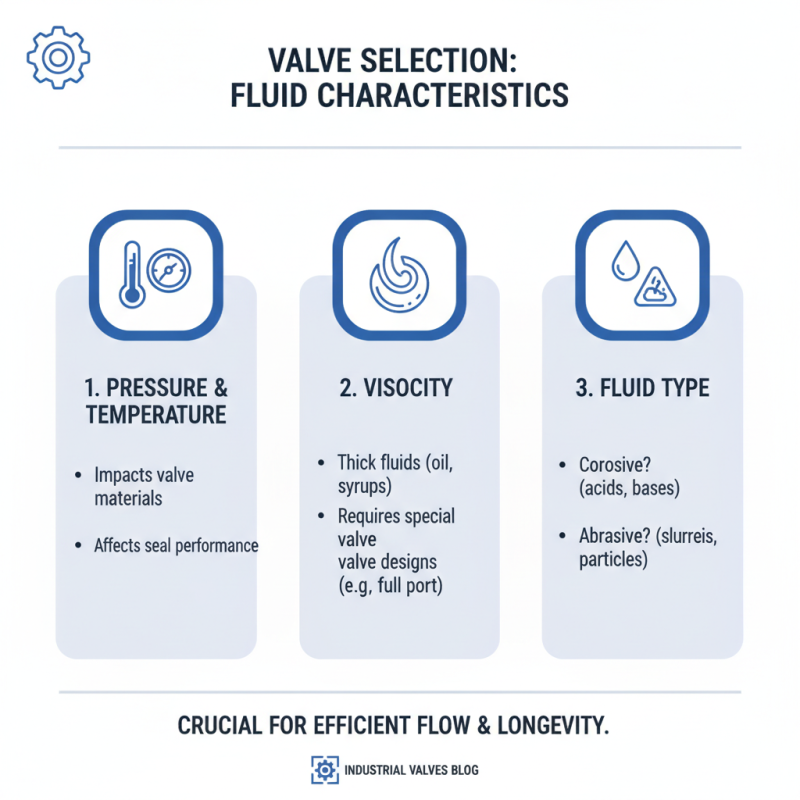

Assessing Fluid Characteristics for Effective Valve Selection

When selecting valves, assessing fluid characteristics is crucial. Fluids can vary significantly. Their pressure, temperature, and viscosity will impact valve performance. Understanding these properties helps in choosing the right valve type. For instance, high-viscosity fluids may require special valve designs to ensure efficient flow.

Fluid composition also matters. Corrosive fluids can damage standard materials. Choosing a valve with compatible materials is essential. Consider the pH level of the fluid too. This detail influences the selection of valve seals and linings. Ignoring these aspects could lead to unexpected failures.

Take a closer look at flow rates. High flow rates may necessitate larger valves. However, oversized valves can lead to inefficiencies. Balancing size and performance is key. Testing under actual conditions can reveal valuable insights. It's a chance to refine choices for optimal performance. Valves that work in theory might not perform well in practice. Careful evaluation of all fluid characteristics will guide you to the best decisions.

Evaluating Pressure and Temperature Ratings for Valve Performance

When selecting valves, evaluating pressure and temperature ratings is crucial. These factors greatly influence a valve's performance and longevity. High-pressure environments require robust materials. The valve's rating should match the system’s demands. A mismatch can lead to failure.

It's essential to consult the specifications for pressure ratings. Each valve has a limit. Exceeding this limit can cause leaks or catastrophic failures. Consider temperature ratings too. If a valve isn't suitable for high temperatures, it can warp. This not only affects functionality but also increases safety risks.

Tip: Always verify the pressure and temperature ratings before purchase. Misjudgments can lead to costly replacements. Test the valve under real conditions. Ensure it performs as expected. Remember, performance issues can stem from overlooked ratings. Reflect on past experiences. Have they led to problems you could avoid this time?

Top 10 Best Valve Selection Tips for Optimal Performance

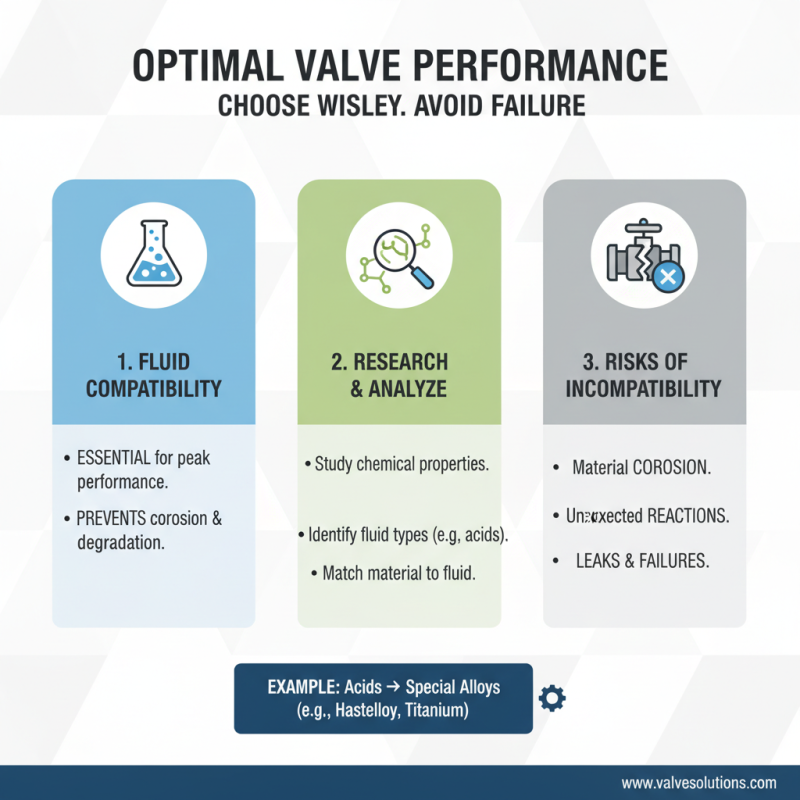

Key Considerations for Valve Material Compatibility

Selecting the right valve material is crucial for optimal performance. Compatibility with process fluids is essential. If you ignore this, you might face serious issues. Materials can corrode, degrade, or react unexpectedly. This could lead to leaks or failures. Conduct thorough research on the chemical properties of the fluids. For example, acids may require special alloys.

Consider temperature and pressure too. Some materials perform well in low pressure but fail in high heat. Test your assumptions under real conditions to prevent mishaps. Be mindful of the environment the valve will operate in. Some materials can’t withstand harsh conditions. Examine how long you need the valve to last. Short-term solutions might save money, but they often lead to costly repairs.

Each application is unique. It’s important not to take shortcuts. Incompatible materials could result in disaster. Consulting with industry experts can provide valuable insights. Validate your choices before finalizing. Reflect on past mistakes in material selection. Learn from them to improve future outcomes. The goal is to ensure safety and efficiency in your operations.

Incorporating Industry Standards and Certifications in Valve Selection

Selecting the right valve is crucial for optimal performance in any industrial setting. Incorporating industry standards and certifications into your valve selection process can greatly enhance operational efficiency. According to the American Society of Mechanical Engineers (ASME), valves that meet established standards can reduce system failures by up to 35%. This statistic emphasizes the importance of compliance in achieving reliability.

One key tip is to ensure that the chosen valve meets specific certifications such as ISO 9001 or API 6D. These certifications reflect the manufacturer's adherence to quality management systems and operational safety. Additionally, consider the valve's pressure rating and temperature range. Selecting a valve not rated for your application can lead to premature failures. This mismatch often goes unnoticed until a system breakdown occurs, causing costly downtime.

When evaluating valve materials, be aware of corrosion resistance and compatibility with the fluids involved. Data from the National Association of Corrosion Engineers (NACE) indicates that improper material selection contributes to 30% of maintenance costs in industries like oil and gas. Remember, not all valves perform equally. Reflect on whether you truly understand the implications of your choices. Selecting the right valve is not just a technical decision; it’s integral to operational success.

Related Posts

-

Top 10 Benefits of Engineered Valves in Industrial Applications?

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

How to Choose the Right Valve Steel for Your Industrial Applications

(780) 669-9420

(780) 669-9420