Blog

- Home

- Blog

10 Best Gate Valves You Need to Know About

Gate valves are essential components in various industries, providing crucial control over fluid flow. Many engineers and technicians often encounter the question, "apa itu gate valve?" These devices are widely used in water supply, oil and gas, and chemical processing, thanks to their ability to offer minimal flow resistance. According to a recent market report, the global valve market size is projected to reach over $150 billion by 2025, highlighting the critical role of gate valves in industrial applications.

The performance of gate valves significantly affects system efficiency. Studies show that improper selection can lead to leaks and increased energy consumption. Certain considerations must be addressed when evaluating different gate valve options. Factors like material choice, pressure rating, and size can impact both durability and functionality. Engineers must weigh these elements carefully.

Despite the known advantages of gate valves, some challenges persist in maintenance and operation. For instance, frequent use can lead to wear, ultimately necessitating replacements. Additionally, the varying designs can complicate installation processes. It is essential for professionals to stay informed on the best products available in the market. The selection of a reliable gate valve can make all the difference.

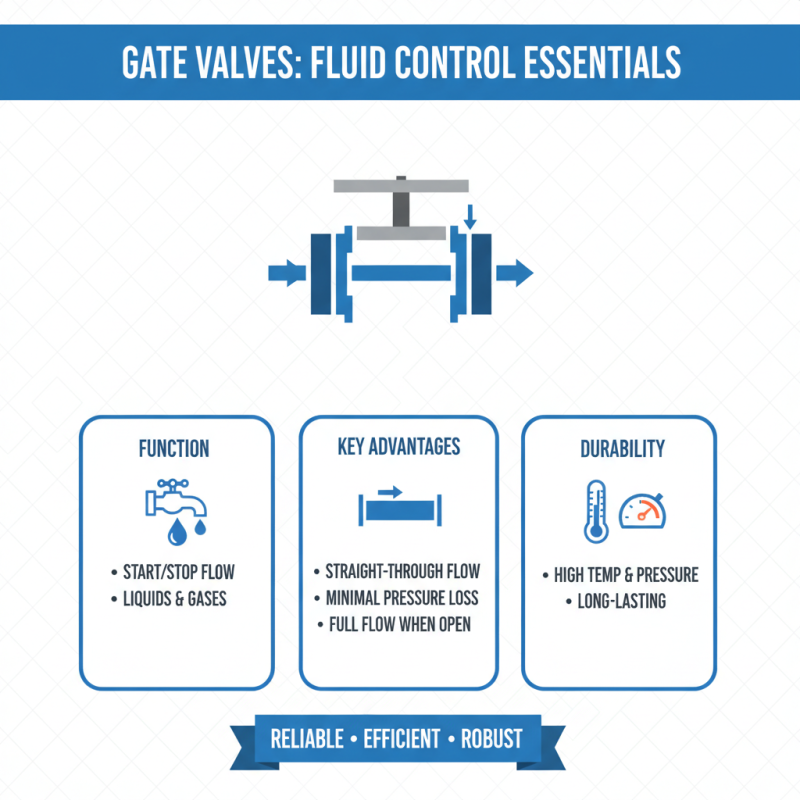

Understanding Gate Valves: Definition and Function in Fluid Control

Gate valves are crucial components in fluid control systems. They function to start or stop the flow of liquids and gases. Unlike other valves, gate valves provide a straight-through flow path, minimizing pressure loss. This characteristic makes them ideal for applications requiring a full flow when fully open. Research from industry reports indicates that gate valves can handle high temperatures and pressure ratings, contributing to their long-lasting durability.

Tips: Ensure proper installation to avoid leaks. Regular maintenance can prolong valve life.

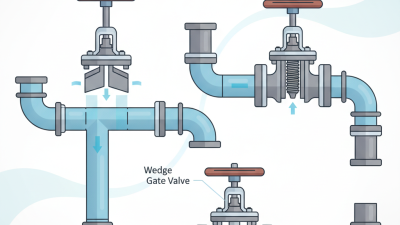

Understanding the mechanics of gate valves can enhance operational efficiency. The disk moves up and down to open or close the valve. This design, however, can lead to slow operation in critical systems. When in the closed position, the disk can wear down quickly under high pressure. Not all gate valves are suitable for throttling. Misuse can lead to inefficiencies and increased operational costs.

Tips: Choose the right valve type for your application. Incorrect selection may cause failures or slow response times.

Key Materials Used in Manufacturing Gate Valves and Their Impact on Performance

Gate valves play a crucial role in various applications. The materials used in their construction significantly impact their performance. Common materials include brass, stainless steel, and cast iron. Each material has unique properties that influence functionality and durability.

Brass is known for its excellent corrosion resistance. It is a popular choice for water applications. However, it may not withstand extreme temperatures. Stainless steel offers greater strength and durability. It's ideal for high-pressure systems. On the downside, it can be more expensive. Cast iron is often used in larger installations due to its robustness. Yet, it can be susceptible to rust if not properly maintained.

**Tip:** Consider your specific application when choosing a material. Evaluate temperature and pressure conditions. This will help ensure a better fit for your needs.

Performance hinges on selecting the right valve. Improper material choice can lead to leaks or failures. Always inspect the valve regularly. Ensure seals and components are in good condition. Maintenance matters in extending the lifespan of gate valves.

**Tip:** Regular checks can prevent costly repairs. Don't overlook small issues. They can escalate quickly into bigger problems.

10 Best Gate Valves You Need to Know About

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Gate Valve A | Brass | 150 | -20 to 180 | Water supply |

| Gate Valve B | Cast Iron | 250 | -10 to 300 | Sewage systems |

| Gate Valve C | Stainless Steel | 500 | 0 to 600 | Chemical processing |

| Gate Valve D | PVC | 80 | -40 to 140 | Irrigation |

| Gate Valve E | Ductile Iron | 200 | -20 to 250 | Oil and gas |

| Gate Valve F | Bronze | 150 | -10 to 200 | Steam systems |

| Gate Valve G | Aluminum | 300 | -20 to 350 | Aerospace |

| Gate Valve H | Carbon Steel | 600 | -20 to 800 | Heavy industry |

| Gate Valve I | Alloy Steel | 1000 | -40 to 900 | Power generation |

| Gate Valve J | Nylon | 50 | -10 to 150 | Food industry |

Top 10 Gate Valves: Specifications and Features to Consider

When selecting a gate valve, several specifications are crucial.

Size matters. A valve must fit the piping system perfectly.

Incorrect sizing can lead to leaks. The material of the valve is also vital.

Common materials include brass, stainless steel, and PVC. Each material has unique properties for different applications.

Pressure rating is another key factor. It defines how much pressure the valve can handle.

Users often forget to check this. A valve under pressure might fail, causing disasters. Additionally, the type of sealing mechanism plays a role.

Some valves use rubber gaskets, while others rely on metal-to-metal seals.

Each type offers different durability and maintenance needs.

Moreover, pay attention to the valve's operation method.

Hand-operated valves require more effort. Automated versions provide convenience but may increase costs.

The design and finish are also important for aesthetic and functional reasons.

A valve may look great but offer poor performance.

An ideal gate valve should strike a balance between form and function.

Always consider your specific needs carefully.

Industry Standards and Certifications for Gate Valves Explained

When selecting gate valves, understanding industry standards is crucial. Gate valves must meet specific criteria for performance and safety. The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) set guidelines that manufacturers follow. These standards ensure that valves can handle high pressures and temperatures, which is vital in industrial applications. In fact, the ISO 9001 certification ensures consistent quality throughout the production process.

Gate valves are often evaluated on their materials and design. A report from the International Organization for Standardization (ISO) indicates that valves made from stainless steel or forged steel are preferred for their durability. However, many valves fail under pressure due to material fatigue or design flaws. This emphasizes the importance of rigorous testing before widespread use.

Moreover, valves should comply with the API (American Petroleum Institute) standards if used in oil and gas sectors. API 6D and API 600 are critical certifications that ensure operational reliability. However, not all products meet these standards perfectly. Remarkably, some manufacturers take shortcuts, leading to failures in the field. Addressing these issues means encouraging better compliance and stricter inspections.

Comparison of Gate Valve Types by Material

Market Trends: Demand and Innovation in Gate Valve Technology

The gate valve market continues to experience significant growth, driven by rising industrial demands. According to a recent industry report, the global gate valve market is forecasted to reach $9.5 billion by 2027, with a compound annual growth rate (CAGR) of 4.5%. As industries evolve, innovations in gate valve technology are crucial. Enhanced designs improve efficiency and reliability, addressing challenges in various sectors.

Recent trends indicate a shift toward automated gate valves. Automation reduces human error and improves operational efficiency. It also aligns with modern smart technology applications. Data shows that around 30% of companies are adopting these automation systems. However, there are concerns over the initial investment costs. These may deter smaller enterprises from upgrading.

Materials used in gate valves also reflect market innovation. New alloys and composite materials are more durable and resistant to corrosion. This is crucial in industries like oil and gas, where the harsh environments can lead to rapid wear. The challenge remains in balancing cost and performance. Companies must carefully consider their choices. Exploring new materials and technologies can sometimes lead to unexpected failures if not thoroughly tested. As they innovate, manufacturers face ongoing scrutiny over reliability and quality standards.

Related Posts

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Top Benefits of Engineered Valves for Industrial Applications

(780) 669-9420

(780) 669-9420