Blog

- Home

- Blog

Best Gate Valve Types You Need to Know for Your Plumbing Projects

In the realm of plumbing, understanding the different types of gate valves is crucial for ensuring optimal performance and reliability in any project. According to industry expert John Smith, a veteran in the plumbing field, "A well-chosen gate valve valve not only enhances system efficiency but also minimizes maintenance issues." This insight underscores the importance of selecting the right gate valve types, as they play a pivotal role in controlling the flow of fluids within pipelines, making them essential components in both residential and commercial plumbing systems.

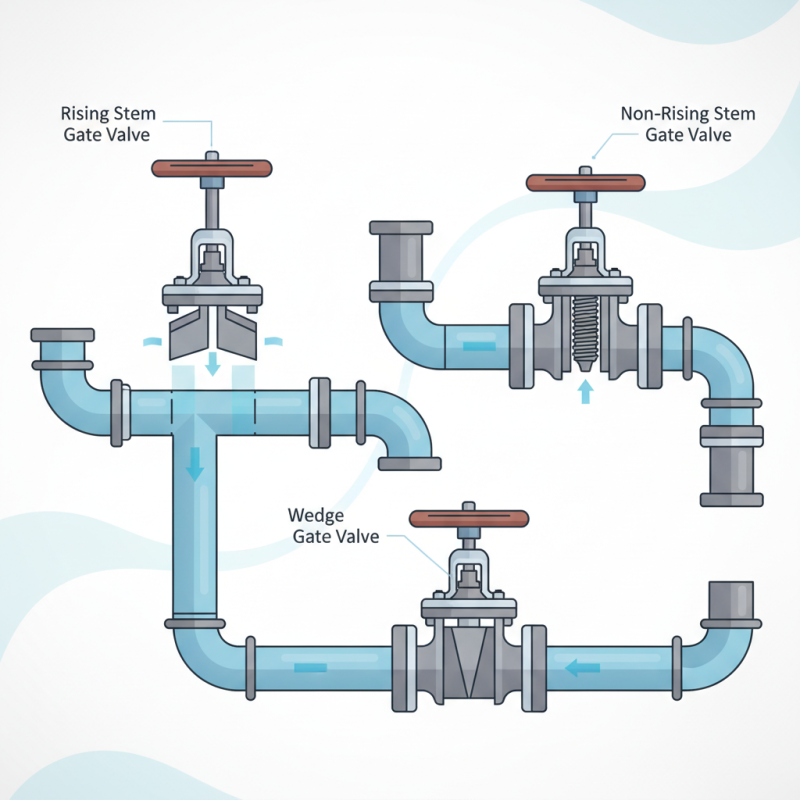

Gate valves, recognized for their design and functionality, are primarily used in on/off service applications. They provide a tight seal, which prevents leaks and maintains system integrity. Different styles of gate valves, such as rising stem and non-rising stem, cater to various requirements and project specifications. By familiarizing oneself with these various types, plumbers and contractors can make informed decisions that ultimately lead to successful plumbing projects. As we delve deeper into the best gate valve types you need to know, we will explore their unique features and the advantages they offer in diverse plumbing scenarios.

Understanding the Basic Functionality of Gate Valves

Gate valves are essential components in plumbing systems, primarily designed to control the flow of fluids. They function by using a gate-like mechanism that can either be fully opened or completely closed, providing a straight flow path with minimal resistance when open. This design is ideal for applications requiring infrequent flow regulation, as the opening and closing motion allows for rapid adjustments. According to a report by the American Society of Mechanical Engineers (ASME), gate valves are widely preferred in high-pressure and high-temperature applications due to their durability and reliability.

Understanding the basic functionality of gate valves can help enhance decision-making in plumbing projects. When fully opened, a gate valve allows for unrestricted flow, which is crucial in industries where fluid dynamics play a significant role, such as in water treatment facilities and industrial processes. The design also minimizes turbulence, which can lead to erosion and wear. According to the Hydraulic Institute, the use of gate valves can lead to a 20% increase in efficiency in certain systems by reducing pressure drops, making them a valuable option for efficient plumbing management.

However, it's important to note that gate valves are not ideal for throttling fluid flow, as partially opening the valve can cause vibration and damage over time. Therefore, understanding the appropriate applications and functionality of different gate valve types is vital for optimizing plumbing systems and ensuring long-term operational reliability.

Different Types of Gate Valves and Their Applications

Gate valves play a crucial role in plumbing projects, serving as reliable control devices for regulating fluid flow in various systems. There are several types of gate valves, each suited for specific applications. The two most common types are wedge gate valves and parallel gate valves. Wedge gate valves employ a disc that forms a wedge shape, providing an effective seal against backflow and are favored in high-pressure applications due to their robust design. In contrast, parallel gate valves feature a flat disc that moves up and down, making them ideal for low-pressure systems and those that require a quick shut-off.

When selecting a gate valve, it's important to consider the material as well. Common materials include cast iron, stainless steel, and PVC, each offering distinct advantages in terms of corrosion resistance and durability. According to data from the International Association of Plumbing and Mechanical Officials, the right choice of materials can enhance the valve's lifespan significantly, reducing maintenance costs.

Tips: Always assess the fluid characteristics—such as temperature and pressure—before choosing your gate valve type. Additionally, regular maintenance and inspection can prevent potential leaks and extend the service life of the valve, resulting in better overall system performance.

Key Features to Consider When Choosing a Gate Valve

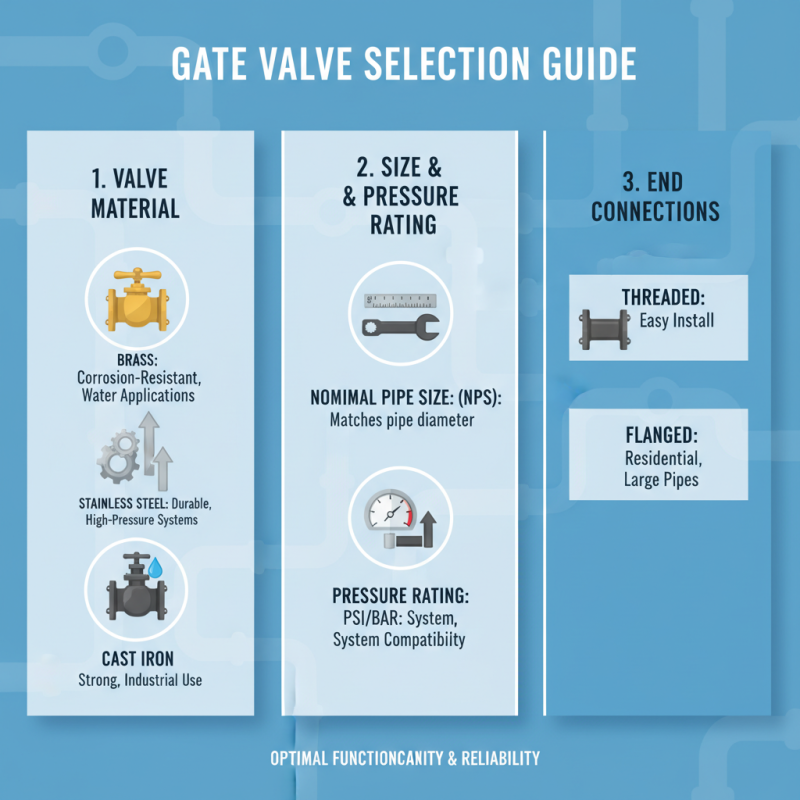

When selecting a gate valve for your plumbing projects, several key features should be considered to ensure optimal functionality and reliability. Firstly, the material of the valve is crucial. Gate valves are available in various materials such as brass, stainless steel, and cast iron. Each material offers different benefits; for example, brass valves are resistant to corrosion, making them suitable for water applications, while stainless steel valves provide durability and strength for high-pressure systems.

Another important factor is the valve's size and connection type. It's essential to choose a gate valve that fits the existing pipeline and matches the connection methods, such as threaded, flanged, or welded connections. Additionally, the design of the valve, including the operation mechanism (manual or automated), can significantly impact the ease of use and maintenance. For instance, manual gate valves might require regular checking and maintenance, while automated options can provide greater convenience for larger systems.

Flow characteristics should also be taken into account. Gate valves are designed to provide minimal flow restriction when fully open, making them an excellent choice for on/off applications where smooth flow is essential. Understanding these key features will assist you in making an informed decision, ultimately enhancing the efficiency and longevity of your plumbing systems.

Installation Techniques for Effective Gate Valve Use

When installing gate valves in plumbing systems, proper techniques are crucial to ensure optimal performance and longevity. First, it is essential to select a suitable location for the valve, ideally within easy reach for future maintenance. Ensure that you have enough space around the valve for wrench access, as this will facilitate smooth operation and reduce wear over time. Additionally, always check for compatibility between the gate valve material and the piping to avoid corrosion or leakages.

When it comes to installation, start by shutting off the water supply to the area where you'll be working. Prepare the pipeline by cleaning the ends and ensuring they are free from debris. Use appropriate sealants or thread tapes on the valve's connections to prevent leaks once the water is turned back on. The valve should be installed in the correct orientation, usually with the handle pointing upwards, to make operation intuitive. Finally, after securing the valve and checking for proper alignment, slowly turn the water supply back on and inspect for any leaks to confirm a successful installation. Remember that regular maintenance will further extend the life of your gate valves.

Best Gate Valve Types and Their Installation Techniques

Maintenance Tips for Prolonging the Life of Gate Valves

Maintaining gate valves is crucial for ensuring their longevity and optimal performance in plumbing systems. One of the first steps in valve maintenance is regular inspection. Check for signs of wear and tear, such as leaks or corrosion, which can indicate that the valve needs servicing or replacement. It's also important to operate the valve periodically, even if it’s not in regular use, to prevent it from becoming stuck or failing due to lack of movement.

Another essential tip for prolonging the life of gate valves is to keep them clean and free from debris. Accumulation of dirt and grime can hinder their operation and lead to build-up that may eventually require more extensive repairs. Regularly flushing the system and ensuring that the valve is in the open position during maintenance can help keep the inner workings free from obstructions. Additionally, applying appropriate lubricants to the valve stem can prevent rust and facilitate smoother operation, thus enhancing its overall lifespan.

Related Posts

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

What is Steel Valves and How They Benefit Your Industrial Applications

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

(780) 669-9420

(780) 669-9420