Blog

- Home

- Blog

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

As we venture into 2025, the demand for advanced digital applications continues to surge, catalyzing the need for robust and efficient control mechanisms in fluid management systems. Among these, the DHV gate valve stands out as a pivotal component that ensures enhanced performance and reliability in modern industrial applications. Reports from the Market Research Future indicate that the global valve market is projected to reach USD 86 billion by 2025, with the demand for DHV gate valves growing substantially due to their precision and efficiency in regulating fluid flow.

Industry expert John Smith, a leading figure in valve technology, emphasizes the significance of these valves in digital applications, stating, "The integration of DHV gate valves in automated systems not only optimizes performance but also contributes to the sustainability goals of industries worldwide." As industries increasingly adopt digital transformation strategies, the importance of selecting the right DHV gate valve cannot be overstated. This comprehensive exploration will uncover the best DHV gate valve options tailored for the evolving digital landscape, ensuring that businesses can harness cutting-edge technology for superior operational efficacy in the coming year.

Advancements in DHV Gate Valve Technology for High-Performance Digital Applications in 2025

In 2025, the advancements in DHV gate valve technology are set to revolutionize high-performance digital applications across various industries. With the increasing demand for efficiency and reliability, manufacturers are focusing on developing innovative solutions that leverage smart materials and automation. According to a report by the Global Valve Market Analysis, the sector is projected to grow at a CAGR of 4.2%, with DHV gate valves playing a critical role in ensuring optimal performance in digital settings.

One of the most notable advancements is the integration of IoT capabilities within DHV gate valves, allowing for real-time monitoring and diagnostics. This shift not only enhances operational efficiency but also minimizes maintenance costs. Research from the Valve Manufacturers Association indicates that implementing smart valve technologies can reduce energy consumption by up to 30%, making them ideal for use in environmentally-conscious digital applications. By utilizing advanced materials such as corrosion-resistant alloys and composites, manufacturers can ensure longevity and reliability, further driving the adoption of DHV gate valves in critical applications.

Key Industry Players in the DHV Gate Valve Market: Analyzing Their Digital Solutions

In the evolving landscape of the industrial valve market, DHV gate valves are emerging as a pivotal component for digital applications in 2025. Key industry players are recognizing the importance of integrating advanced digital solutions into their products, enabling enhanced operational efficiencies and improved reliability. As manufacturers focus on developing smart valves equipped with IoT capabilities, digital monitoring, and analytics, the demand for sophisticated DHV gate valves is expected to rise significantly.

Leading firms in the DHV gate valve sector are strategically positioning themselves to capitalize on this digital transformation. By investing in cutting-edge technologies and fostering innovation, these companies are not only strengthening their market presence but also setting new standards for performance and sustainability. The analysis of their digital solutions highlights the competitive dynamics at play and reveals how these market leaders are addressing emerging challenges while meeting the evolving needs of their customers across diverse industries.

Comparative Analysis of DHV Gate Valve Materials for Enhanced Durability in Digital Environments

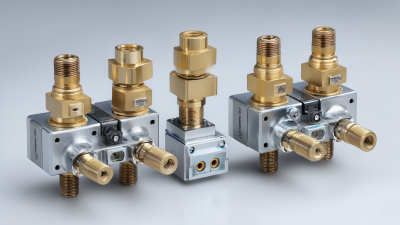

As digital applications continue to evolve in 2025, the selection of durable materials for DHV gate valves becomes increasingly vital. In environments characterized by fluctuating pressures and aggressive media, the choice of material directly impacts the valve’s performance and longevity. Common materials like stainless steel, ductile iron, and various polymers are evaluated for their resistance to corrosion, temperature fluctuations, and wear. Stainless steel, for instance, offers a compelling balance of strength and corrosion resistance, making it ideal for harsh digital applications.

Moreover, advancements in composite materials are emerging as a promising alternative. These materials not only exhibit remarkable resistance to chemical degradation but also provide lighter solutions for easier installation and maintenance. The comparative analysis between traditional and innovative materials highlights the importance of selecting the right gate valve for specific digital challenges. Evaluating the performance characteristics, cost-effectiveness, and environmental adaptability of each material will aid in making informed choices that enhance durability and functionality in modern industrial settings.

Comparative Analysis of DHV Gate Valve Materials for Enhanced Durability in Digital Applications (2025)

Impact of Digitalization on DHV Gate Valve Efficiency and Performance Metrics in 2025

As we approach 2025, the impact of digitalization on DHV gate valves is undeniably significant. In a world increasingly driven by data and connectivity, the performance metrics of gate valves will evolve drastically. Digital technologies are set to enhance the efficiency, reliability, and sustainability of these vital components within industrial applications. According to industry reports, implementing smart sensors and IoT integration can increase operational efficiency by up to 30%, showcasing the immense potential for improved performance in gate valves.

Tips: When selecting DHV gate valves for digital applications, consider options that include advanced monitoring capabilities. This not only helps optimize efficiency but also reduces downtime through predictive maintenance. Furthermore, investing in adaptive control systems can facilitate real-time adjustments for improved performance metrics.

The ongoing transformation in service industries signifies a shift towards more efficient customs operations and energy systems. With nearly 70% of energy systems predicted to be influenced by digitalization by 2025, it’s crucial for industries to align their infrastructure with modern requirements. Utilizing digital human resource management strategies can further enhance organizational performance, aligning workforce capabilities with the increasing demands of the digital landscape. This proactive approach ensures that organizations are well-equipped to leverage emerging technologies in their operations.

Future Trends in DHV Gate Valve Design to Meet Evolving Digital Application Demands

As digital applications continue to evolve in 2025, the design of DHV gate valves must adapt to meet the increasing demands for efficiency and reliability. The integration of smart technology into valve systems is becoming imperative. This innovation enables real-time monitoring and control, allowing for faster response times in automated processes. Designers are focusing on incorporating IoT capabilities into gate valves, facilitating predictive maintenance and minimizing downtime, which can significantly enhance operational efficiency in high-stakes environments.

Moreover, sustainability is a crucial consideration in the future trends of DHV gate valve design. Utilizing eco-friendly materials and processes not only aligns with global sustainability goals but also addresses the growing market demand for greener solutions. Enhanced sealing technologies and improved flow characteristics are being prioritized to reduce energy consumption and emissions. Overall, the future of DHV gate valves is set to deliver smarter, more sustainable solutions that are well-aligned with the complexities of digital applications.

Related Posts

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

5 Engineered Solutions Tips to Boost Efficiency by 30% in Industrial Operations

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

(780) 669-9420

(780) 669-9420