Blog

- Home

- Blog

Top Benefits of Engineered Valves for Industrial Applications

In the ever-evolving landscape of industrial applications, the importance of selecting the right components cannot be overstated. Engineered valves, specifically designed and tailored for specific operational demands, have emerged as a pivotal innovation in this sector. Dr. Emily Harper, a renowned expert in fluid dynamics, emphasizes the critical role these valves play in enhancing system efficiency. She states, "Engineered valves not only optimize operational performance but also significantly reduce maintenance costs and downtime, making them indispensable for modern industrial processes."

Engineered valves are meticulously crafted to meet stringent specifications, ensuring reliability under varying conditions. From manufacturing to energy production, the versatility and precision of these valves contribute to smoother and more effective industrial operations. By incorporating advanced materials and innovative designs, engineered valves deliver superior performance that standard valves often cannot match. This tailored approach allows industries to address unique challenges, ultimately leading to improved safety, efficiency, and sustainability within their operations.

As industries continue to face increasing demands for efficiency and reliability, the adoption of engineered valves will undoubtedly play a crucial role. Their benefits extend beyond mere functionality; they offer strategic advantages that enhance overall productivity. The integration of engineered valves into industrial systems represents a forward-thinking solution that can pave the way for future advancements in technology and engineering.

Understanding Engineered Valves in Industrial Settings

Engineered valves play a crucial role in modern industrial applications, enhancing efficiency and safety in a variety of sectors, including oil and gas, water management, and manufacturing. These valves are designed to endure extreme conditions and perform reliably, which significantly reduces maintenance costs and downtime. According to a report by MarketsandMarkets, the global market for engineered valves is projected to reach $120 billion by 2026, indicating a growing reliance on these integral components within industrial settings.

One of the key advantages of engineered valves is their ability to handle diverse fluids and pressures. They are often constructed from advanced materials that resist corrosion and wear, making them ideal for withstanding harsh environments. Additionally, engineered valves offer superior flow control, resulting in optimized processes and energy savings. The American Society of Mechanical Engineers (ASME) notes that implementing high-performance valves can improve operational efficiency by up to 25%, underscoring their importance in industrial infrastructure.

Furthermore, the integration of smart technologies in engineered valves is revolutionizing their functionality. The use of sensors and automation allows for real-time monitoring and predictive maintenance, reducing the risk of failures and enhancing safety protocols. A study by the International Energy Agency highlights that industries adopting smart valve technologies can reduce energy consumption by 15-30%, showcasing the potential for significant operational savings and environmental benefits.

Key Advantages of Using Engineered Valves Over Traditional Options

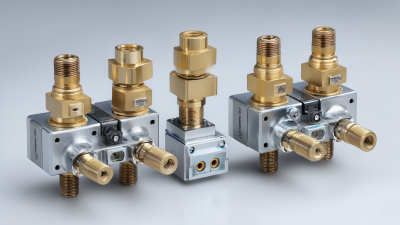

Engineered valves offer a range of benefits that make them superior to traditional valve options in industrial applications. One of the primary advantages is their precision design, which enhances performance and reliability. Unlike standard valves, engineered valves can be tailored to specific requirements, ensuring optimal flow characteristics and minimizing pressure drops. This customization results in improved energy efficiency and reduced operational costs, making engineered valves a smart choice for industries looking to maximize their resources.

Another significant advantage is the advanced materials used in engineered valves. These materials are often more resilient, offering greater resistance to corrosion, wear, and extreme temperatures compared to conventional options. This durability not only extends the lifespan of the valves but also reduces maintenance needs and downtime, leading to increased productivity for industrial operations. Furthermore, engineered valves are designed with safety features that enhance operational reliability, promoting a safer working environment in high-stakes applications. The combination of precision, advanced materials, and enhanced safety makes engineered valves a compelling alternative for industries aiming to improve their process efficiency and operational integrity.

Top Benefits of Engineered Valves for Industrial Applications

| Benefit | Engineered Valves | Traditional Valves |

|---|---|---|

| Durability | Higher resistance to wear and tear | Often requires more frequent replacement |

| Efficiency | Designed for optimal flow characteristics | May cause pressure drops and inefficiencies |

| Customization | Tailored solutions for specific applications | Limited options for specific needs |

| Maintenance | Lower maintenance requirements | Higher maintenance costs and frequency |

| Leak Resistance | Enhanced sealing technology | Higher risk of leaks |

Enhanced Performance Metrics of Engineered Valves in Various Industries

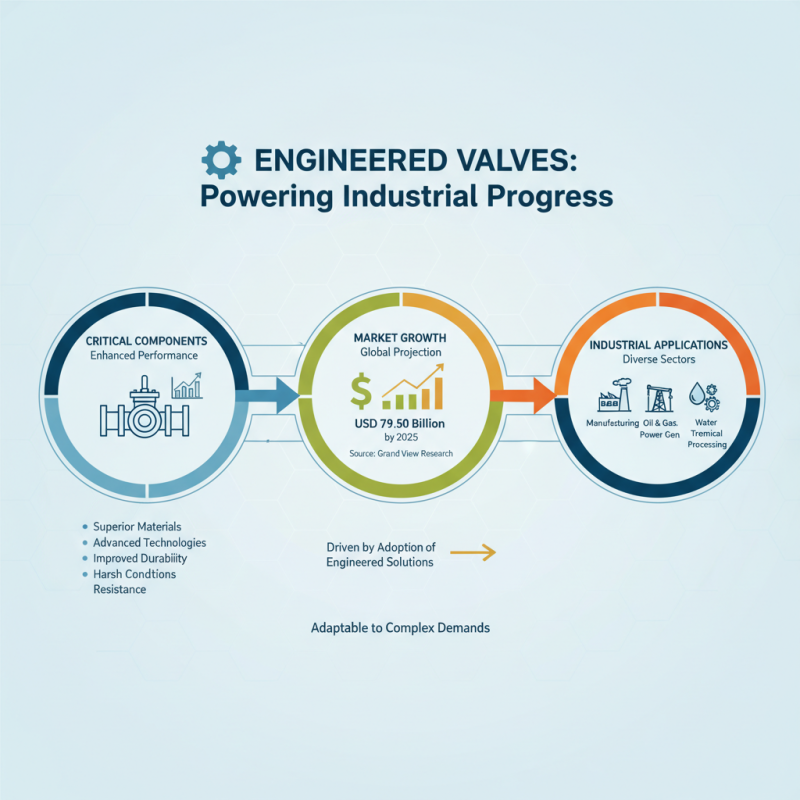

Engineered valves have emerged as critical components in numerous industrial applications, driving enhanced performance metrics across different sectors. According to a report by Grand View Research, the global market for industrial valves is projected to reach USD 79.50 billion by 2025, largely driven by the increasing adoption of engineered solutions that adapt to the complex demands of modern industries. These advanced valves are designed with superior materials and technologies, resulting in improved durability and resistance to harsh operating conditions.

In the oil and gas sector, for instance, engineered valves contribute to heightened efficiency and safety by minimizing leakage and optimizing flow rates. A study by the American Society of Mechanical Engineers (ASME) indicates that advanced valve technologies can reduce maintenance costs by up to 20% while enhancing operational reliability. Furthermore, in the water treatment industry, engineered valves are capable of withstanding extreme pressures and corrosive environments, leading to an increase in system longevity and a decrease in downtime. This illustrates the significant role that engineered valves play in achieving sustainability goals and operational excellence in various industrial applications.

Material Engineering: How It Affects Valve Durability and Efficiency

Material engineering plays a crucial role in the performance and longevity of engineered valves used in industrial applications. The choice of materials dictates not only the valve's durability but also its efficiency in handling various media under changing conditions. According to a recent report by the International Journal of Industrial Engineering, valves constructed from advanced composite materials can exhibit upwards of 30% higher durability and resistance to corrosion compared to traditional metals. This enhancement leads to fewer maintenance cycles and extended service life, ultimately reducing operational costs for manufacturers.

When selecting engineered valves, it's vital to consider the specifics of material composition. For instance, the use of high-performance alloys can significantly improve the valve's ability to withstand extreme temperatures and pressures, which are common in industries such as oil and gas, chemical processing, and power generation. A study published by the American Society of Mechanical Engineers indicates that valves made from high-strength stainless steel can withstand pressures exceeding 250 bar without a failure, thus ensuring safety and reliability in critical applications.

Tips: Always consult with a materials engineer to assess the best material options for your valve applications. Conduct regular maintenance checks to ensure that the selected materials are performing as expected. Additionally, keep abreast of advancements in material science to capitalize on innovations that could enhance efficiency and durability in your operations.

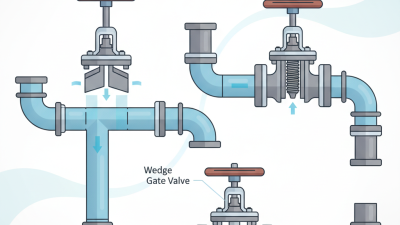

Innovative Designs in Engineered Valves for Optimal Flow Control

Engineered valves have become pivotal in achieving optimal flow control within various industrial applications. Their innovative designs address common flow challenges by offering precise regulation, which is critical in processes where accuracy can significantly impact efficiency and safety. Recent industry reports indicate that the comprehensive use of engineered valves can reduce leakage rates by up to 50%, underscoring their role in enhancing operational reliability. This is particularly beneficial in sectors such as oil and gas, where even minor discrepancies can lead to significant operational costs and safety hazards.

The versatility of engineered valves is also noteworthy. Advanced materials and actuator technologies allow these valves to operate effectively under extreme temperature and pressure conditions, making them indispensable in high-stakes environments. According to a market analysis by Research and Markets, the global market for engineered valves is projected to grow at a CAGR of 7.6% through 2027, driven by increased demand for automation and smart flow control systems. This growth reflects a broad recognition of the value brought by innovative designs in engineered valves, which not only enhance performance but also promote energy efficiency and sustainability in industrial processes.

Related Posts

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Top Insights on Through Valve Technology for 2025 and Beyond

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Exploring the Future: Top Valve Engineering Innovations of 2025

(780) 669-9420

(780) 669-9420