Blog

- Home

- Blog

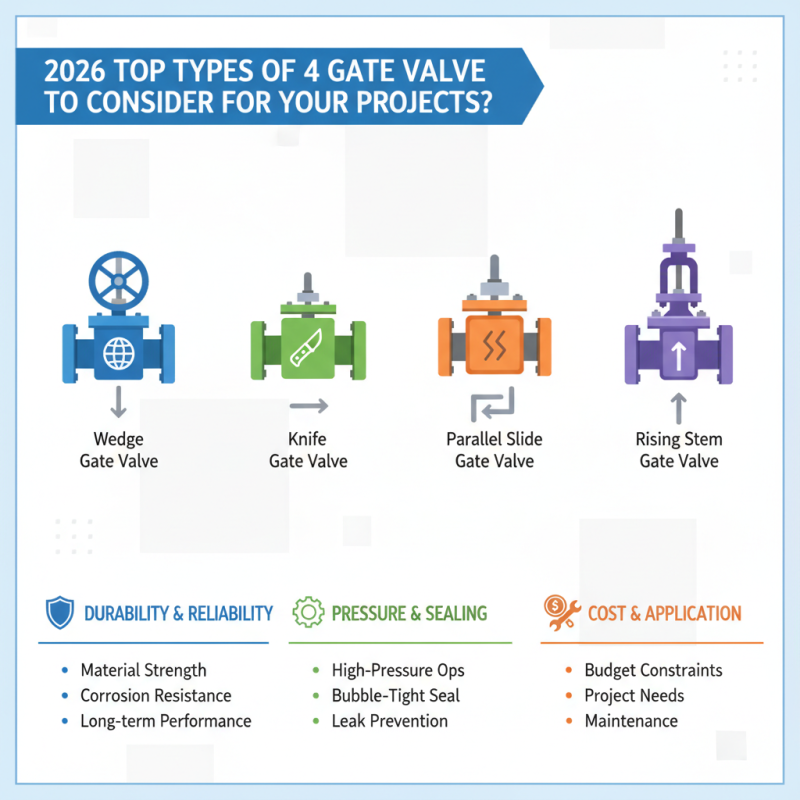

2026 Top Types of 4 Gate Valve to Consider for Your Projects?

When choosing the right equipment for your projects, understanding the various types of 4 gate valves becomes crucial. These valves play a vital role in managing fluid flow in piping systems. With numerous designs available, selecting the right one can be overwhelming.

In 2026, the demand for efficient 4 gate valves will likely escalate. Factors like durability, reliability, and performance are essential in your decision-making process. There are different configurations to consider, each with unique advantages. For example, some valves provide better sealing capabilities, while others excel in high-pressure situations.

However, the choice isn't always clear-cut. Some options may seem perfect at first glance but might not perform well long-term. It’s important to evaluate the projects’ specific needs carefully. Reflect on which type of 4 gate valve aligns best with your requirements and budget constraints. Knowing both strengths and weaknesses will enhance your selection process.

2026 Overview of 4 Gate Valve Types in Industrial Applications

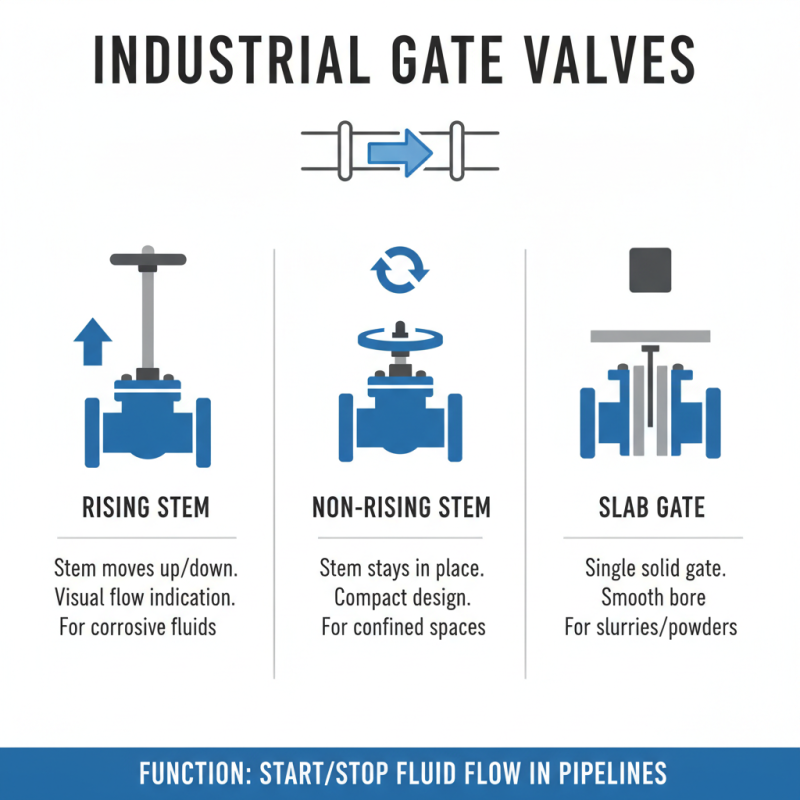

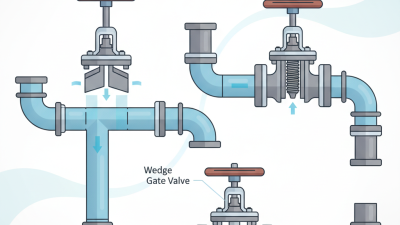

When considering gate valves for industrial applications, understanding the types available is crucial. Gate valves play a significant role in controlling fluid flow. They are used in pipelines to either completely stop or allow flow. Common types include rising stem, non-rising stem, and slab gate valves. Each type serves different needs in various industries.

Rising stem gate valves are ideal for high-pressure applications. They provide better visibility on the valve’s open or closed status. However, they require more space to operate. Non-rising stem valves are suitable for tight spaces. They maintain a lower profile, making installation easier in cramped areas.

Tips: Check the valve size carefully. The right fit is essential for functionality. Also, consider the material. Different materials react differently under pressure and temperature.

Slab gate valves are simpler but can have issues with sealing. They are easier to manufacture, which can reduce costs. However, long-term reliability may be a concern. Always factor in the operational environment. This can impact longevity and performance. Each project may demand a different choice of valve type. Reflect on these factors carefully before making a decision.

Key Factors Influencing Selection of 4 Gate Valves for Projects

When considering gate valves for projects, several key factors play a crucial role. One major aspect is the material used in the valve construction. Different materials offer varying levels of durability and corrosion resistance. According to industry reports, stainless steel valves are highly favored in petrochemical applications, whereas ductile iron valves excel in water treatment. Selecting the right material can significantly impact the longevity and efficiency of the valve system.

Another important factor is the valve size and pressure rating. A well-matched size ensures that the valve operates optimally within the system. Data shows that poorly sized valves can lead to increased wear and higher operational costs. This can be further amplified when pressure ratings do not align with system requirements. Therefore, precise measurements are vital. It’s common to see professionals overlooking these details, leading to potential system failures.

Lastly, consider the valve’s design and installation ease. Some designs are more complex than others, which can complicate replacement and repairs. Industry feedback highlights that simpler designs tend to reduce maintenance time. However, over-simplification might limit functionality. This balance is essential for project success. Reflecting on these elements can lead to better decision-making and more successful project outcomes.

2026 Top Types of 4 Gate Valves to Consider for Your Projects

Performance Metrics: Comparing Popular 4 Gate Valve Designs

When selecting a 4 gate valve for your project, several performance metrics stand out. Start by assessing the flow capacity. This determines how much fluid can pass through the valve. Different designs influence this rate significantly. A robust and efficient design can enhance overall system performance.

Another vital metric is pressure drop. This directly affects energy consumption. If a valve creates a high pressure drop, it can lead to inefficiencies. Some designs have better flow characteristics, which minimize this issue. For instance, a well-designed valve can reduce turbulence and ensure smooth flow.

Lastly, consider the ease of operation. Some valves require complex mechanisms, while others are straightforward. The maintenance needs also vary. A valve that needs frequent adjustments can lead to increased downtime. Reflecting on these factors can guide you in choosing the right valve design for your needs.

Future Trends: Innovations in 4 Gate Valve Technology for 2026

In 2026, the landscape of 4 gate valve technology is evolving rapidly. Innovations focus on improved efficiency, durability, and sustainability. Manufacturers are exploring advanced materials that resist corrosion and wear. This is crucial for industries reliant on reliable valve performance. Enhanced seal designs also promise to reduce leakage and maintenance needs.

Smart technology integration is gaining traction. Some 4 gate valves now feature IoT connectivity. This allows real-time monitoring and data collection. However, issues around data security and system compatibility remain a challenge. Not all users may be ready to embrace such innovations fully.

The trend towards automation in valve operations continues. The push for automation can enhance operational efficiency but also raises concerns about job displacement. Choosing the right valve for a project can be daunting. Balancing traditional methods with new advancements requires careful assessment.

2026 Top Types of 4 Gate Valve to Consider for Your Projects

| Valve Type | Material | Pressure Rating | Temperature Rating | Applications | Innovative Features |

|---|---|---|---|---|---|

| Standard Gate Valve | Carbon Steel | 150 PSI | -20°C to 180°C | Water, Oil, Gas | Corrosion Resistance |

| Metal Seated Gate Valve | Stainless Steel | 300 PSI | -40°C to 400°C | High-Temperature Steam | Extended Lifespan |

| Plastic Gate Valve | PVC | 100 PSI | -10°C to 60°C | Chemical Processing | Lightweight and Durable |

| Electrically Controlled Gate Valve | Cast Iron | 200 PSI | -20°C to 150°C | Oil and Gas Pipelines | Remote Operation Capability |

Market Analysis: Demand and Supply of 4 Gate Valves Across Industries

The demand for 4 gate valves has seen substantial growth across various industries. Recent market reports indicate an annual growth rate of 4.5% from 2021 to 2026. Industries such as oil and gas, water treatment, and power generation are major contributors to this demand. The versatility of gate valves in controlling flow makes them essential in these sectors.

Supply chain dynamics, however, present challenges. Recent disruptions have led to delays in production and shipping. According to industry analyses, approximately 25% of manufacturers reported difficulties in sourcing materials. This fluctuation creates uncertainty in pricing and availability. In response, companies are exploring alternative materials and suppliers, aiming for a more resilient supply chain.

Additionally, environmental regulations are reshaping the market. Industries are under pressure to adopt more sustainable practices. This shift can complicate the sourcing of compliant gate valves. Some manufacturers may struggle to adjust rapidly, leading to potential supply shortages. It is vital for stakeholders to stay informed and proactive in navigating these market challenges.

Related Posts

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

2026 Top Gate Valve Types for Your Industrial Applications?

-

Top Gate Valve Types Explained for Your Industrial Needs?

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

(780) 669-9420

(780) 669-9420